LAUNCH TyreChanger(TWC-502RMB)

9

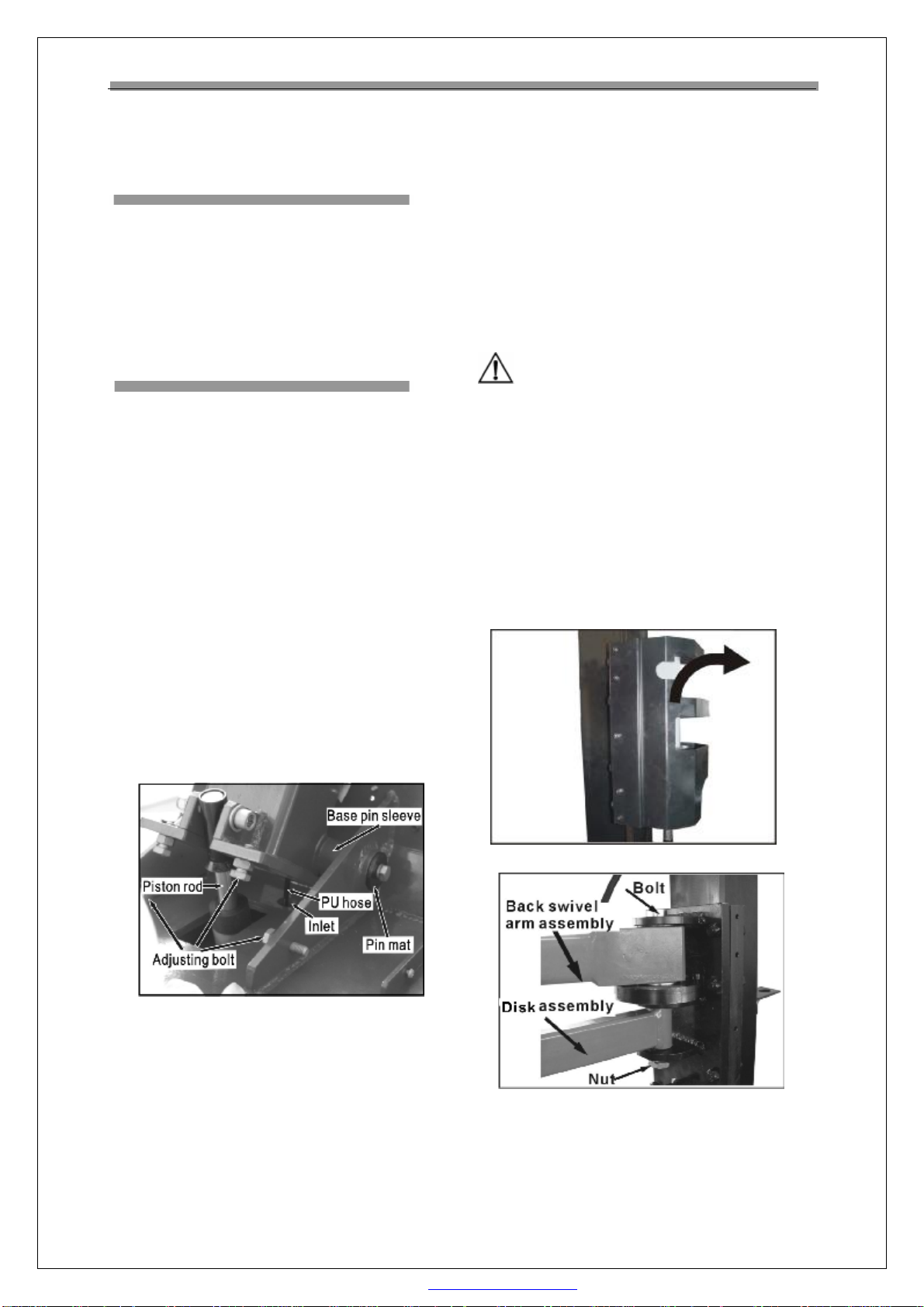

column. Also, there are two bolts on the side

plates of theseatfor limiting thehorizontal

position of the tilting column. Before operation,

the two bolts on the base plate of the tilting

column should be on the same horizontal level to

ensure bearingthe sameweight. Theside ends

of two bolts should be away 0.5—1mmfrom the

vertical plates of the tilting column.

HorizontalArmand Hexagonal

ColumnClamping Unit

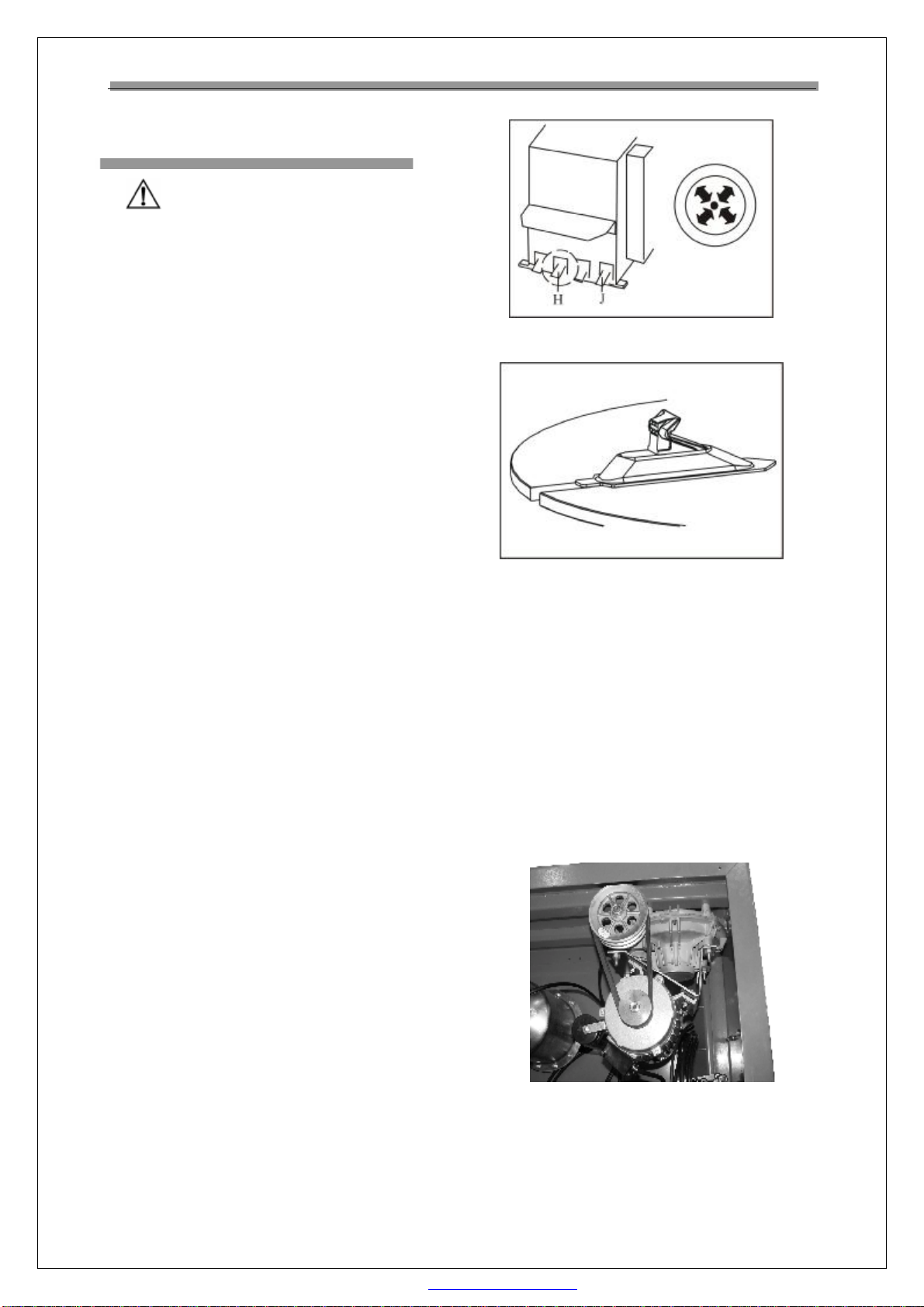

lAs shown in the figure 22 use (air valve) locking

button Jonthe handle(k) tocontrol movement of

the clamping cylinder.Whenthumbeddown the

button, the external shellsof clamping cylinders

(b and g) arepushed out. Their external shells

touch lockingboards (candh). The tiltingof the

boards will lock thehorizontal arm and the

hexagonal column.

Fig.22

lWhen the button is pressed out by index finger,

the clamping cylinder (b andg) will be drawn

back. The tilting boards(c andh) willrelax to

loose the horizontal armand thehexagonal

column. When it doesn’twork, nuts (e and i)

can be tightened or loosened for adjustment.

SupplementaryArm

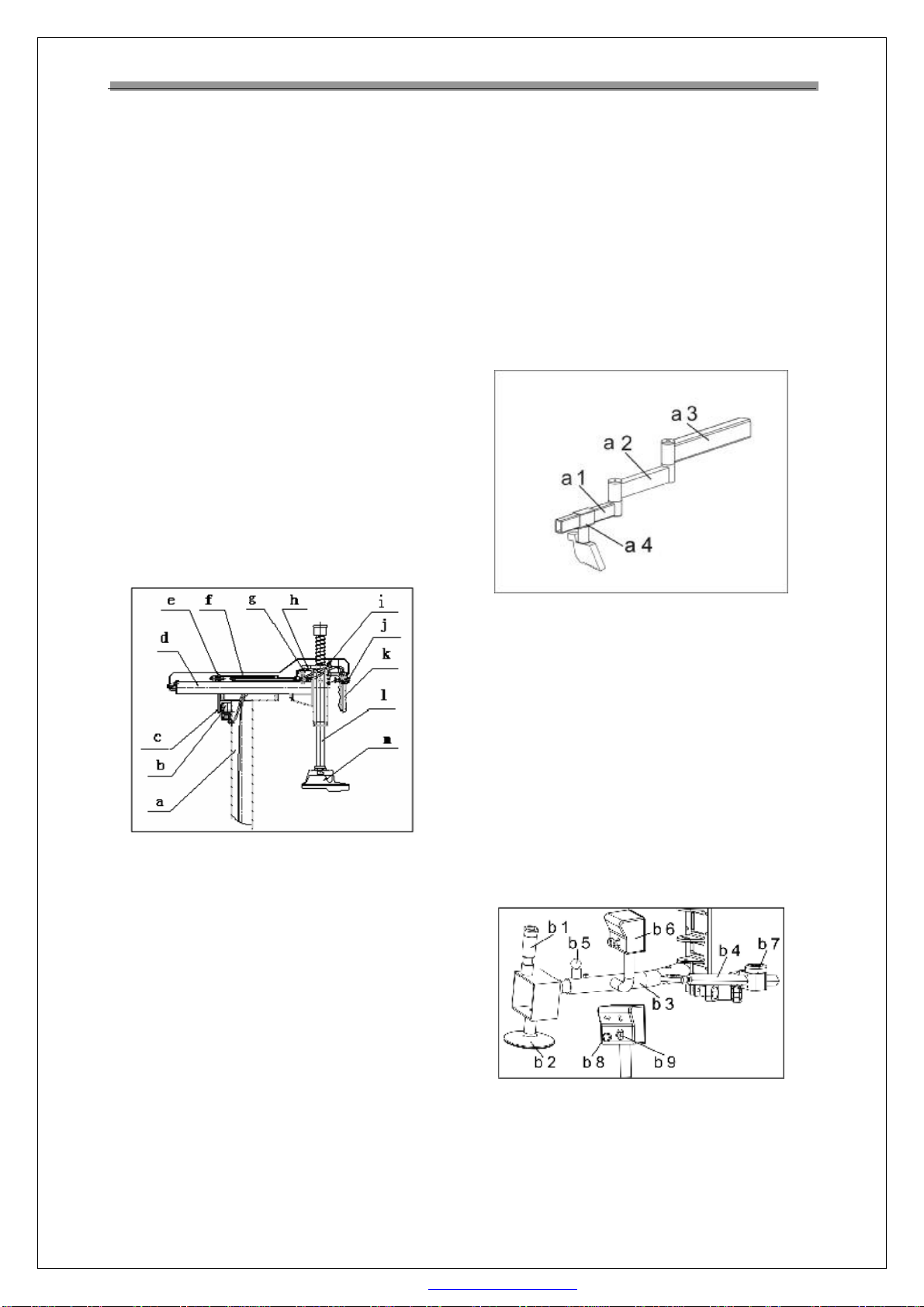

lFigure 02-1 shows structureof the

supplementary arm that consists of such three

main function units as roller,press block and disk.

The horizontal column unit, swivel armunit, disk

unit and sliding sleeve integrate them together

and can moveup and down alongthe sliding

column under controlof rise/fall control lever on

the control box.When therise/fall controllever is

lifted, the supplementary arm moves up along

with the sliding sleeve. Contrarily,when the

rise/fall controllever ispresseddown, the

supplementary arm moves down. If it causes

flutter when supplementary arm moves up and

down, adjust the four locking screws on the side.

lGroup aof supplementary arm (fig.23). fore

swivel arm (a1) and middle swivel arm(a2) both

can turn freely around corresponding axis of back

swivel arm(a3). press block(h)can move on fore

swivel arm (a1)and fixed on back offore swivel

arm (a1) for centering and pressing rim.

Fig.23

lGroup bof supplementary arm(fig24).roller of

disk arm(b1),with pressblock(h)and roller 1(c1)

is used to mount upper tyre bead under condition

without using mounting head.It also has other

functions. disk(b2) is used to demount tyre by

lifting tyre.switch between roller ofdisk arm (b1)

and disk (b2) by knob (b5).On control box(b6),

there is lockbutton(b8)and rise/fall control

lever(b9). disk arm is controlled by lock

button(b8). lock cylinder(b7) can lock by locking

slide bar(b4), so to control movement of disk arm.

Rise/fall control lever(B9) isto control movement

up and down of the supplementary arm.

Fig.24

lGroup cof supplementary arm as in

fig.25.Choose roller 1(c1) according to need and

fix it on fore part ofslide rod(c4) by knob(c3).

Turn lock bar(c5) to lock slide rod (c4.)

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn