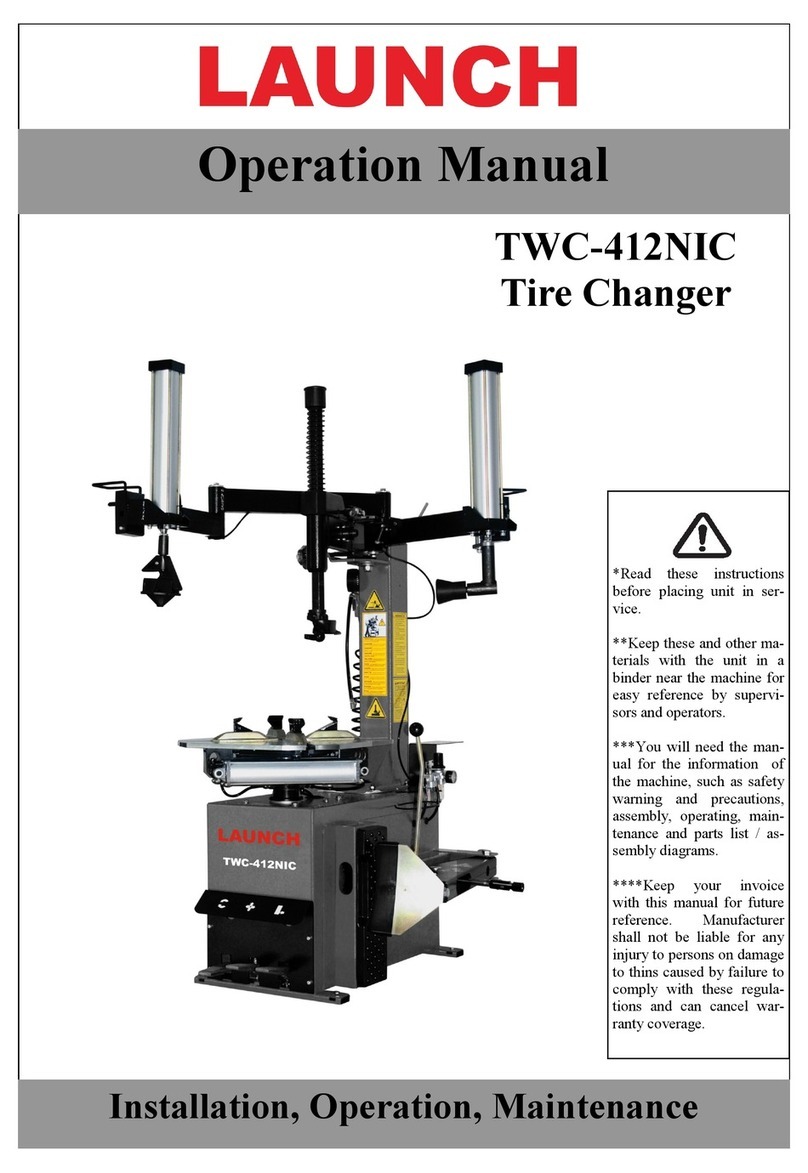

LAUNCH Tire Changer TWC-581

Installation of Tool box

Install the tool box on one side of the cabinet

according to figure 14.

Fig.14

Transportation

It is advisable to transport the machine with fork lift

vehicle.

Movable parts such as the assist arm assembly,

swing arm assembly, bead breaker arm assembly,

must be fastened to the cabinet tightly with rope

to avoid damage to machine and injuries to

people during transportation.

Avoid excessive tilt in transportation.

Don’t drive the fork lift vehicle carrying the

equipment too fast.

Keep the machine at as low a position as

possible and make sure it doesn’t overturn in

transportation (pay attention to the position of the

gravity center).

Positioning

The place to install the machine should be in

accordance with safety regulations:

The machine should be installed in a place close

to the main power and compressed air source.

Install the machine on a smooth concrete floor or

other surface with hard flooring. 4 sets of

anchor bolts (M10×1 0) can be used to fasten

the machine onto the floor to avoid vibration and

noise.

Leave enough space around the machine for

proper operation and maintenance. The space

should be no less than 1M (39”) in front and on

the two sides of the machine and 0.7 M (29”)

behind it.

If the machine has to be installed outdoors, a

protective shelter should be built.

Note:

For the safety and proper operation, keep the

machine at least 0.7 M (29”) away from any wall.

Power and Air Connections

Before installation, verify the electrical power

source and the compressed air are in

accordance with the specifications on the

nameplate. Any electrical connection should be

performed by a specially trained technician.

The power socket should be at a place within the

sight of the operator. The advisable height is

between 0.6 – 1.7M. (24”-6 ”)

In case the main voltage is not stable, a voltage

stabilizer should be used between power source

and the machine.

The machine should be well grounded.

The tire changer is not equipped with

overload protection. Please connect power

according to the circuit diagram included in the

User’s manual. Otherwise, the manufacturer

will not be responsible for any accidents.

Adjusting

Attention:

Make sure that the power supply, air

sources and the oil level in the oil cup are in

accordance with the requirements.

Initial Operation (Fig. 01-1)

Note:

The four pedals must be kept at the original

position.

Press down the pedal (J) to turn the turntable

clockwise;

Lift the pedal (J) to turn the turntable

counter-clockwise;

Press down pedal (I) to move bead breaker;

release it to restore;

Press down pedal (H) to move the jaws on the

turntable outward; pedal again to move them

inward;

When the up down control lever is lifted, the

assist arm device will go up.

When the control lever is lowered down, the

assist arm device will go down.

When the Inflation pedal U

Fig.01-1

is lightly

pressed, air will blast from the air hose

connected with the barometer (mounted on tool

box). When the pedal is pressed down to the

lowest position, air will quickly blast out from

behind the four jaws (the end of the slides)