5 7 143 5. "( . )

Failure to comply with all aspects ofthese instructions may resultin

unsafe performance.

All installations must comply with relevant state and local authority

requirements.

Flush the system thoroughly before fitting the valve:

It is CRITICAL that all debris is flushedfromthe pipework prior to

installing the valve.Not flushing the system properly is the most

commoncause of system difficulties.

Commission the valve:

Every valve is factory-set to a nominal temperature of 105°F. Every

must be adjusted on-site to ensure correctdelivery of the

desired mixed water temperature ,as installation conditions can vary

from site to site.

Check:

• Measure and note all site parameters (pressure , temperature, etc.)

and check against the specifications of the chosen valve. If the site

conditions are outside those specified for the valve then they must

be rectified prior to installing the valve.

• Valve MUST NOT be subjected to heat during installation as this

may damage the valve internals.

• Valve MUST NOT be fitted on steam-supplied systems, but to

water systems only.

• Valve MUST NOT be used on low pressure or instantaneous

heating systems.

• Valve MUST NOT be frozen. If the valve is installed in a situation

where freezing is a possibility, then suitable insulation must be

fitted to prevent damage to the valve.

• DO NOT use excess thread sealant (in liquid, tape or other form)

as this may cause the valve to fail.

Leave a copy of these instructions with the client for future reference.

Recommend to the client that the valve be checked annually to ensure

its continued function.

California Proposition 65 Warning

Warning: product contains chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm.

(Installer: California law requires that this warning be given to

the consumer)

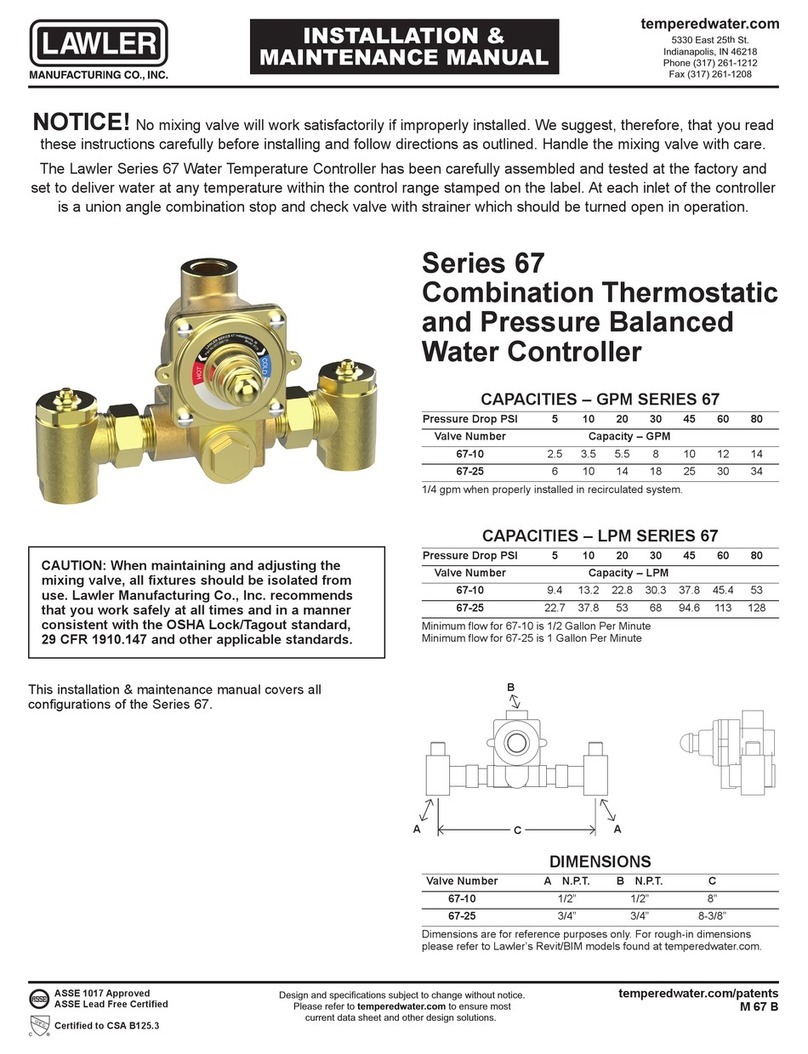

VALVE SPECIFICATIONS

Outlet temperature range: 95~115°F(35~46°)

Temperature, hot supply: 180°F max(82°)

Temperature, cold supply: 40~80°F(4~27°)

Temperature stability(nominal): ±5°F(±2.8°)- See Note 1.

Temperature differential: 1/2”- ±10°F(±5.5°)-See Note 2.

(between hot supply and outlet temperature) 3/4”- ±10°F(±5.5° )-See Note 2.

Hydrostatic pressure: 125psi max(1000kPa)

Permitted supply pressure variation: ±20%-See Note 3.

Flow rate @ 45psi pressure loss: 1/2”- 9gpm (66L/min)

3/4”- 11gpm

Flow rate,minimum: 0.5gpm(2L/min)

Flow rate,maximum: 1/2”- 10gpm @ 60psi pressure lost

3/4”- 12gpm @ 60psi pressure lost

Notes:

1. As testedin accordance with ASSE 1070.

2. This is the minimum difference required between the valve outlet

temperature and the hot supply temperature to ensure shut-off of outlet

flow in the event of cold supply failure, inaccordance with ASSE1070.

3.Maximum permittedvariation in either supply pressure inorder to

control the outlet temperature to with ±5°F .Excessive changes insupply

pressure may cause changes in outlet temperature, that exceed ±5°F.

Installation

Manual

MODEL 570

Thermostatic Mixing

Valve

CSA B 125.3 Approved

5330 East 25th Street

Indianapolis, Indiana 46218

Phone (317) 261-1212

Fax (317) 261-1208

www.temperedwater.com