Lawler 61 Series Instruction Manual

temperedwater.com

5330 East 25th St.

Indianapolis, IN 46218

Phone (317) 261-1212

Fax (317) 261-1208

INSTALLATION &

MAINTENANCE MANUAL

Design and specifications subject to change without notice.

Please refer to temperedwater.com to ensure most

current data sheet and other design solutions.

CAUTION: When maintaining and adjusting the

mixing valve, all xtures should be isolated from

use. Lawler Manufacturing Co., Inc. recommends

that you work safely at all times and in a manner

consistent with the OSHA Lock/Tagout standard,

29 CFR 1910.147 and other applicable standards.

temperedwater.com/patents

M 61 E

ASSE 1017 Approved

ASSE Lead Free Certied

Certied to CSA B125.3

NOTICE! No mixing valve will work satisfactorily if improperly installed. We suggest, therefore, that you read

these instructions carefully before installing and follow directions as outlined. Handle the mixing valve with care.

Series 61

Thermostatic Water

Controller

This installation & maintenance manual covers all

congurations of the Series 61.

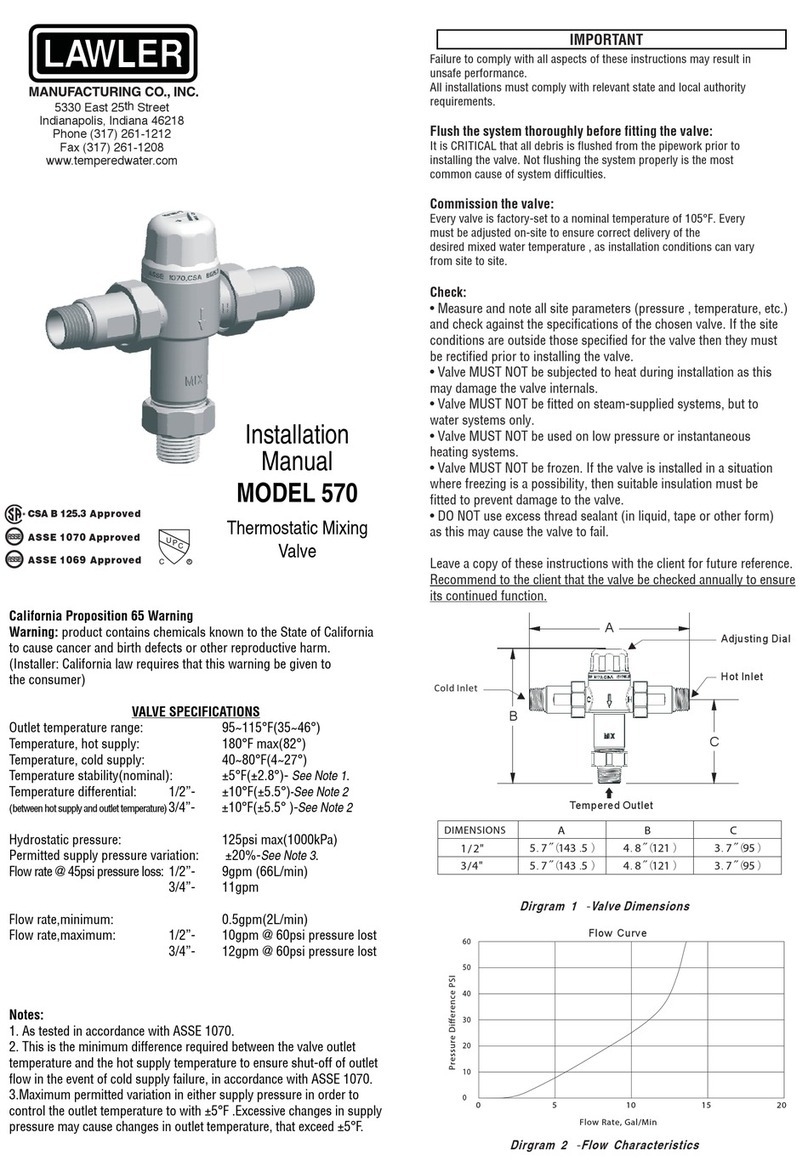

CAPACITIES – GPM SERIES 61

Pressure Drop PSI 5 10 20 30 45 60 80

Valve Number Capacity – GPM

61-10 2.5 3.5 5.5 8 10 12 14

61-15 3.5 5.5 8.5 11 15 18 20

61-25 6 10 14 18 25 30 34

1/4 gpm when properly installed in recirculated system.

CAPACITIES – LPM SERIES 61

Pressure Drop PSI 5 10 20 30 45 60 80

Valve Number Capacity – LPM

61-10 9.4 13.2 22.8 30.3 37.8 45.4 53

61-15 13.2 20.8 32 41.6 56.7 68 75.7

61-25 22.7 37.8 53 68 94.6 113 128

Minimum ow for 61-10 & 61-15 is 1/2 Gallon Per Minute

Minimum ow for 61-25 is 1 Gallon Per Minute

DIMENSIONS

Valve Number A N.P.T. B N.P.T. C

61-10 1/2” 1/2” 8-1/2”

61-15 1/2” 1/2” 8-1/2”

61-25 3/4” 3/4” 8-5/8”

Dimensions are for reference purposes only. For rough-in dimensions

please refer to Lawler’s Revit/BIM models found at temperedwater.com.

72906_6110_STD_DRW_NODIMS.pdf

B

A A

C

Maintenance

The Lawler thermostatic water controller, if correctly

installed and properly used, should require very little

attention or maintenance. However, every mechanical

device, including water controllers, deserves some care.

Strainers should be checked periodically and, if needed,

cleaned as outlined under “INSPECTING AND CLEANING

OF VALVE.” To test controller for proper setting and

operation—proceed as follows:

1. Place handle in hottest position. Mixing valve should

deliver water at the temperature stamped on the label.

Standard setting is 110°F. If not 110°F, readjust to 110°F

according to “TEMPERATURE ADJUSTMENT” procedure in

another paragraph of this manual.

a. If the temperature is below 110°F and the

following procedures for adjusting do not increase

temperature, see paragraph “CHECKING COLD

WATER SHUT-OFF.”

b. If the temperature is above 110°F and the

following procedures for adjusting do not decrease

temperature, see paragraph “CHECKING HOT

WATER SHUT-OFF.”

Checking Cold Water Shut-Off

1. Turn adjustment handle to cold position. In this position

a full ow of cold water should pass through the

controller.

2. Shut the hot water stop valve and open cold water

stop valve. Cold water should ow momentarily until

thermostat cools and then ow should be reduced to

a negligible amount with adjustment handle set to the

warmest position.

Failure to do so will indicate that:

a. Piston is sticking and unit must be cleaned.

b. Spring has lost its strength and should be replaced.

c. On rst test, if water does not ow, this can be

normal if temperature of cold water is below 75°F.

A quick test is to momentarily turn on hot water so

the thermostat warms up. If ow then starts, the

thermostat is good. Failure to obtain ow when rst

starting or when valve is cold is a normal reaction.

Checking Hot Water Shut-Off

1. With adjustment handle set in hot position, mixing valve

should deliver water at the temperature stamped on the

nameplate.

2. Shut cold water supply to controller. The hot water

should be reduced to a negligible amount.

Failure to do so will indicate:

a. Hot water supply isn’t 20°F above the required

maximum temperature setting.

b. Piston is sticking. Unit must be cleaned.

c. Thermostat has lost charge.

Performance

The Series 61 will maintain outlet temperature to within

3°F under any of the following conditions, providing

the recommended minimum ow and minimum supply

temperature differentials are not exceeded:

• reduction to minimum ow (1/2 or 1 GPM)

• 30°F change in hot water temperature

• 30°F change in cold water temperature

• 30% drop in inlet supply pressure

Maximum Inlet Conditions

Pressure: 125 psig

Temperature: 200°F

Recommended Conditions

Minimum Flow

1 Gallon Per Minute for 61-25

1/2 Gallon Per Minute for 61-10 & 61-15

Minimum Temperature Differential

Hot and cold water inlets must have a minimum 20°F

differential from the outlet set temperature.

Three-Way Protection

Three-Way protection is provided with Lawler’s patented

backseat.

1. Thermostat Protection.

Lawler’s exclusive design cuts water ow if the

thermostat’s liquid motor fails.

2. Hot Supply Protection.

Responds automatically if the hot water supply is

interrupted, or temperature changes.

3. Cold Supply Protection.

Guards against scalding if the cold supply is interrupted.

Lawler Thermostatic Valves adjust for changes in both input

temperature and pressure, maintaining constant output.

Operating Principle

Cold: With the stop valves open and adjustment handle in

the cold position, the plunger is positioned in the liner so

that the hot ports are closed and the cold ports are open,

allowing only cold water to pass through the controller.

Warm: When the adjustment handle is moved toward the

warm position, the spring forces the piston upward, opening

the hot water ports and closing the cold water ports. As

the warm water ows over the thermostatic element,

which is solidly lled with a thermo-sensitive liquid, the

liquid changes in temperature. This change in temperature

causes an expansion or contraction of the liquid, resulting

in a movement of the exible bellows. This movement is

transferred to the pushrod which in turn moves the piston.

This moving action proportions the amount of hot and cold

water allowed to enter the mixing valve in accordance with

the adjustment handle setting.

Inspecting and Cleaning the Valve

Shut off hot and cold water supply to mixing valve. Set

mixing valve handle on maximum hot position. Remove

body screws. Turn mixing valve handle toward “COLD”

position until it forces cover off valve body. The thermostat

can now be examined.

Checking the Thermostat

If there is a question as to the thermostat being good,

hold thermostat under cold water faucet and insert an

eraser capped pencil into the center of thermostat.

Make a reference mark where pencil protrudes from the

thermostat. Now place the entire thermostat into hot water,

approximately 125°F, for about one minute. Remove

thermostat from water, examine the reference mark on the

pencil again. At this temperature, it should extend out from

former position about 1/8’’. If it does not, a new thermostat

should be installed.

Checking the Piston and Liner

With a 1 3/8” socket (1/2” N.P.T.) or 1-5/8” socket (3/4”

N.P.T.) remove piston and liner assembly. Check to see if

the piston moves freely in the liner. If the piston is sticking,

place the assembly in a mildly acidic cleaner. Work the

piston in the liner until free. Rinse the assembly in water. Be

sure to wear protective gloves when cleaning the assembly.

If the assembly is corroded or pitted, it should be replaced.

Check O-ring #17 and replace if necessary.

Piston and liner assembly consists of parts included in

assembly #12. (Only available as an assembly.)

Temperature Adjustment

Valves are normally set at the factory for 110°F maximum

outlet temperature. If it is desired to change this setting,

proceed as follows:

1. Allow water to ow through the controller.

2. Remove handle screw.

3. Turn adjustment handle to maximum hot position and

hold in that position.

4. With 5/32” allen key turn adjusting screw #7

clockwise to reduce maximum outlet temperature

and counterclockwise to increase maximum outlet

temperature. Screw should not be turned more than 1/2

turn at a time without testing outlet water temperature.

5. When temperature is correct, replace handle screw.

If outlet temperature is to be 15°F or more higher than that

on the label, contact factory or Lawler representative for a

special thermostat.

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

(Installer: California law requires that this warning

be given to the consumer.)

For more information: www.oehha.org/prop65

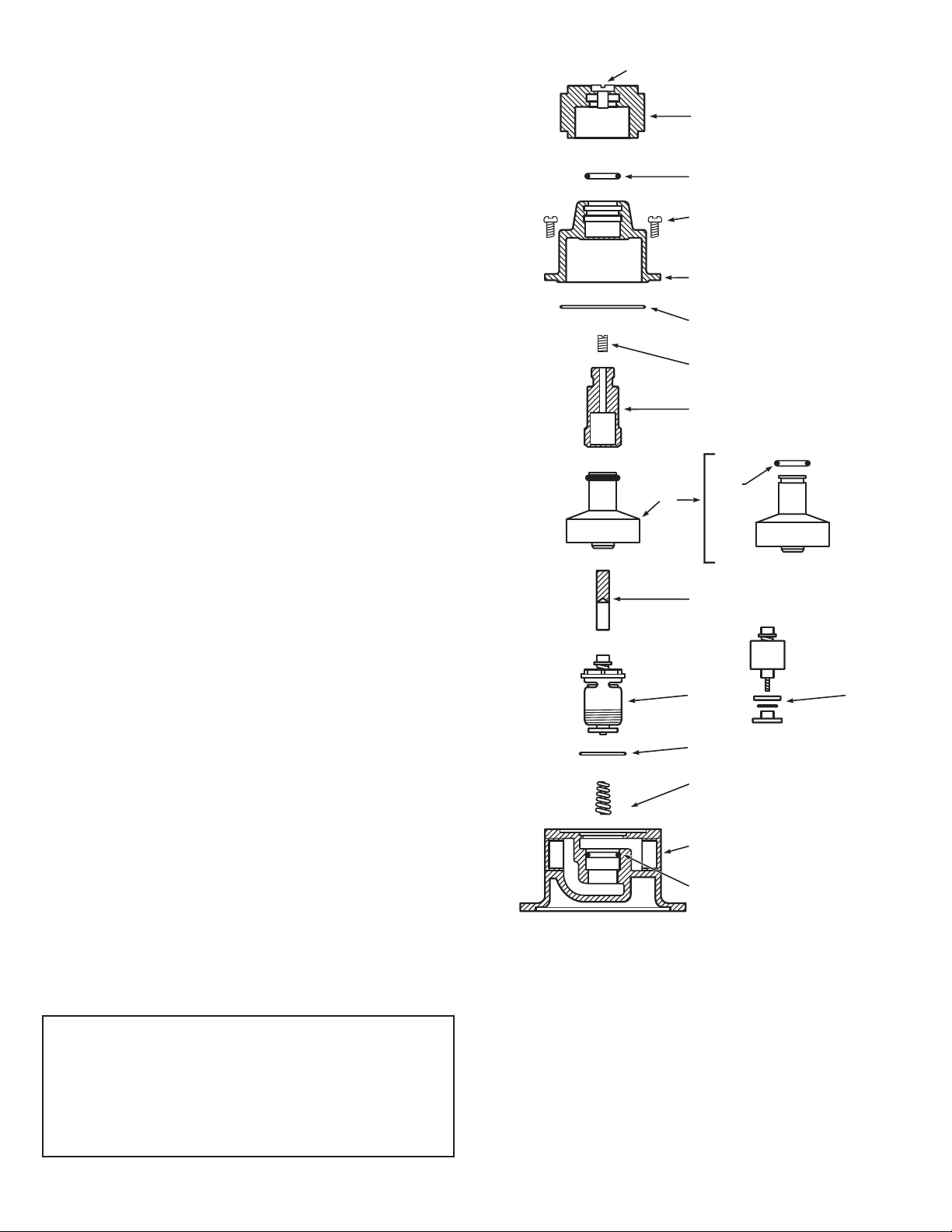

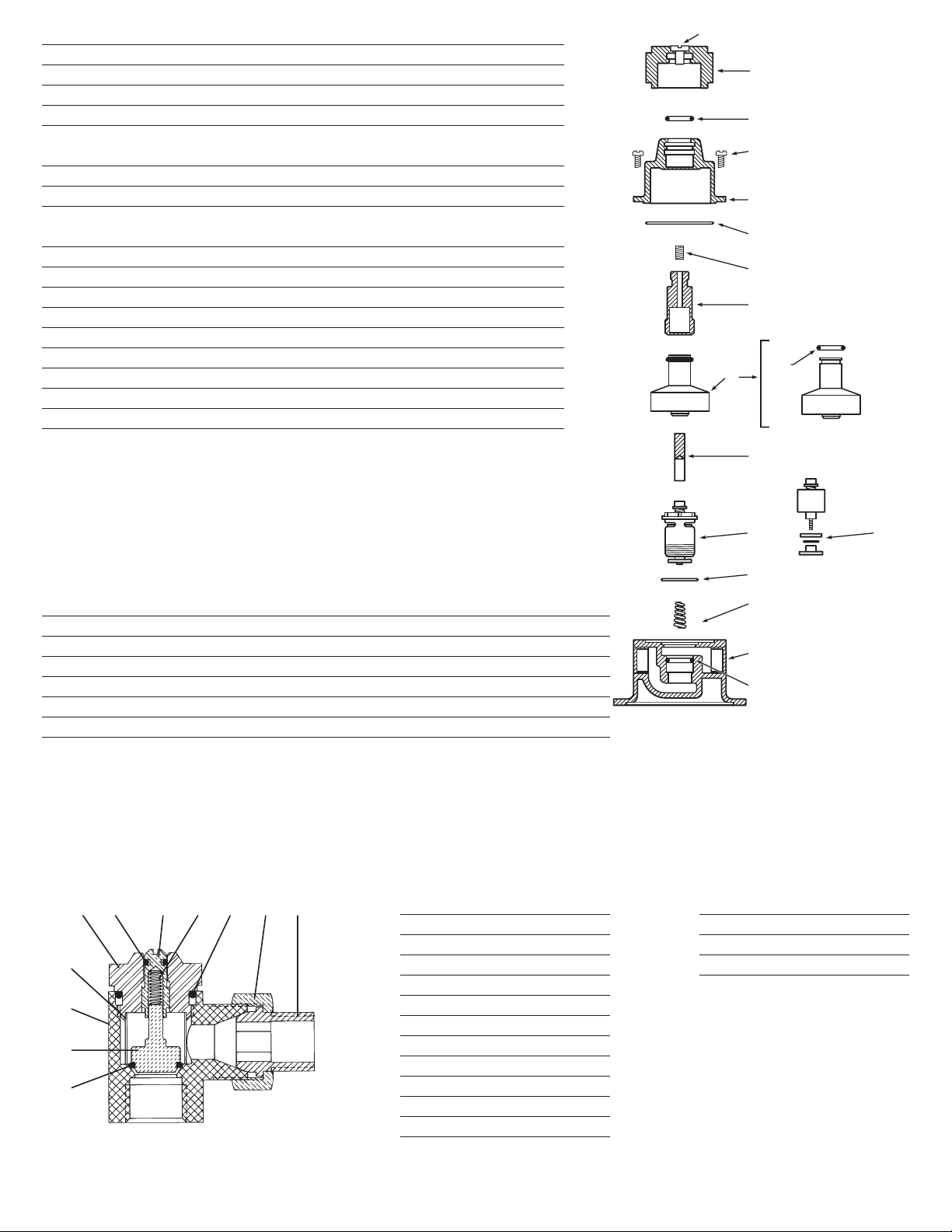

Thermostatic Water Controller Cut-away

Series 61 cut away new

9

3

4

5

6

7

8

11

12

15

17

16

10

2

1

13

14

Series 61 cut away new

9

3

4

5

6

7

8

11

12

15

17

16

10

2

1

13

14

Item Description 1/2” Part No. 3/4” Part No.

1 Handle Screw 7628-00 7628-00

2 Handle 8062-00 8062-00

3 Cover O-Ring — —

4 Cover Screw 7185-00 117-00

5 Cover — —

(Available only in Cover & Spindle Assembly)

6 Body Gasket — —

7 Adjusting Screw 8262-00 8262-00

8 Spindle — —

(Available only in Cover & Spindle Assembly)

9 Thermostat Assembly See Below See Below

10 Thermostat O-Ring — —

11 Pushrod 153-03 153-03

12 Piston, Liner & Backseat Assembly See Below See Below

13 Hot Seat Disc — —

14 Liner Seat O-Ring — —

15 Valve Spring 8223-00 8063-00

16 Body — —

17 Body O-Ring — —

Numbers shown below are for a 1/2” 61-10 and 3/4” 61-25 with standard brass nish and

temperature range of 85-135.Consult price sheets or contact the factory on kits with other ow

rates and temperature ranges.

Item Description Contains 61-10 61-25

A Complete Repair Kit B-C-D-4-11-15 78001-01 78002-01

B O-Ring and Gasket Kit 3-6-10-13-14-17 79959-00 79960-00

C Piston, Liner & Backseat 12-14 72904-11 72905-11

D Thermostat Assembly 9-6 72903-11 72903-11

E Cover & Spindle (Brass) 3-5-7-8 72940-00 72941-00

Cover & Spindle (Chrome) 3-5-7-8 72940-01 72941-01

Does not include parts for stop & checks

Repair Kits and Assemblies

Rebuilding Kit for Inlet Stop & Checks

NOTE:* Components are not included in repair kit.

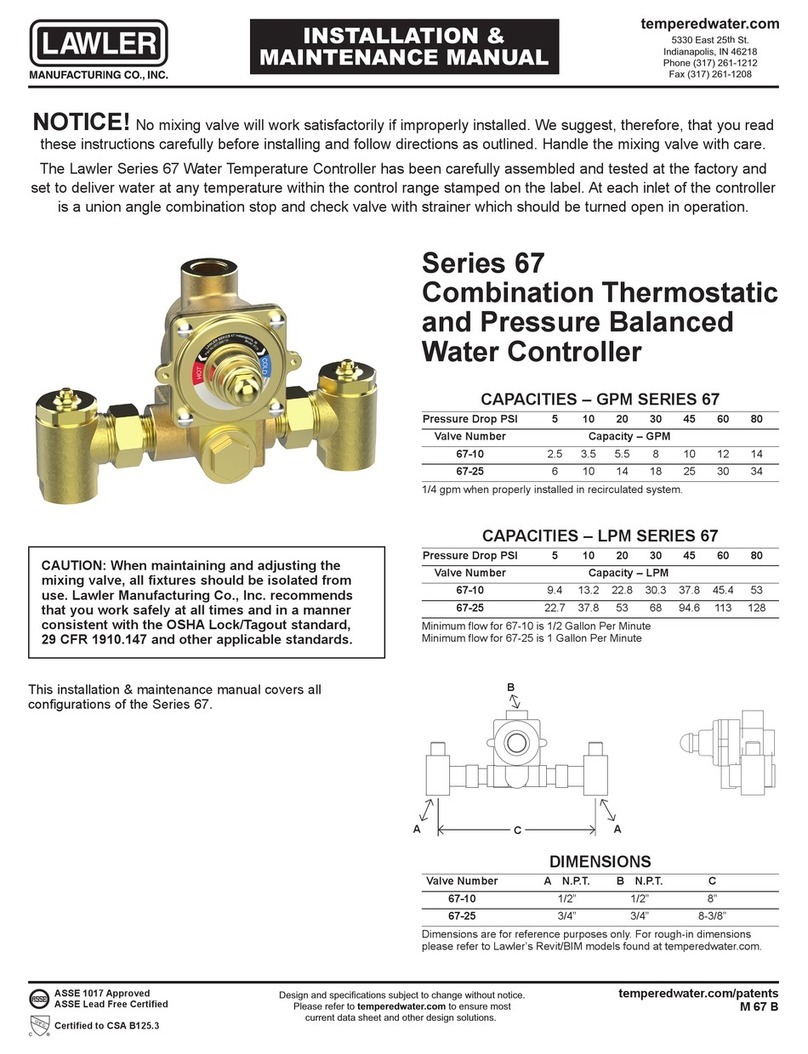

Item Description

1 Adjustment Stem

2 O-Ring Seal

3 Spring

*4 Bonnet

*5 Body

6 O-Ring Disc Holder

7 O-Ring

8 Strainer

*9 Union Nut

*10 Union Tailpiece

11 Bonnet O-Ring

Repair Kit for Two Stop & Checks

Valve Part No.

1/2” 79902-03

3/4” 79907-12

7

6

5

8

42 9103111

This manual suits for next models

3

Other Lawler Control Unit manuals

Lawler

Lawler 3000 Instruction Manual

Lawler

Lawler NEPTUNE EMX 075 Instruction Manual

Lawler

Lawler 911E Instruction Manual

Lawler

Lawler 410 Instruction Manual

Lawler

Lawler 4000 Series Instruction Manual

Lawler

Lawler 911E Instruction Manual

Lawler

Lawler 570 User manual

Lawler

Lawler 67 Series Instruction Manual

Lawler

Lawler 310 Instruction Manual

Lawler

Lawler 911 E/F Series User manual