Checking Mixing Valve

1. CHECKING COLD WATER SHUT-OFF. Shut off hot

supply keeping cold supply open. At rst, full volume of

cold water should pass through valve. The volume of

cold water should then be reduced to a very small ow.

Failure of this to occur would indicate:

a. Piston #15 is stuck in one position. Unit has to be

cleaned.

b. Valve spring #18 has lost its strength and must be

replaced.

c. Cold water is in excess of 80°F.

2. CHECKING HOT WATER SHUT-OFF. Open both the

hot and cold supplies to mixing valve. Water should ow

through valve at 110°F. If not, adjust valve as explained

under “TEMPERATURE ADJUSTMENT.”

Now shut off the cold water supply to the mixing valve.

A properly operating mixer will shut off the hot water

almost instantly with hot water temperature supplying

the mixing valve at least 15 degrees higher than

maximum setting.

Failure to do so would indicate:

a. Dirt between the hot seat #17 in liner #21 and

piston #15 prevents it from closing. Unit has to be

cleaned.

b. The piston #15 could be stuck so that it cannot

move because of scale or some other deposit in

water. Unit has to be cleaned.

c. The thermostat has lost its power and has to be

replaced with a new one.

Inspection and Cleaning Valve

Shut off hot and cold water supply to mixing valve. Remove

body screws #9. Take the cover #26 off valve body. The

thermostat, piston and liner can now be examined.

Checking the Thermostat

If cold seat #23 on thermostat is worn or deeply indented,

remove it and replace with a new one. If there is a question

as to the thermostat being good, hold thermostat under

cold water faucet and insert an eraser-capped pencil into

the center of thermostat. Make a reference mark where

pencil protrudes from the thermostat. Now place the entire

thermostat into hot water, approximately 125°F for about

one minute. Remove thermostat from water, examine the

reference mark on pencil again. At this temperature, it

should extend out from former position about 1/8”. If it does

not, a new thermostat should be installed.

CAUTION: Extreme care should be exercised when

placing thermostat in and out of hot water.

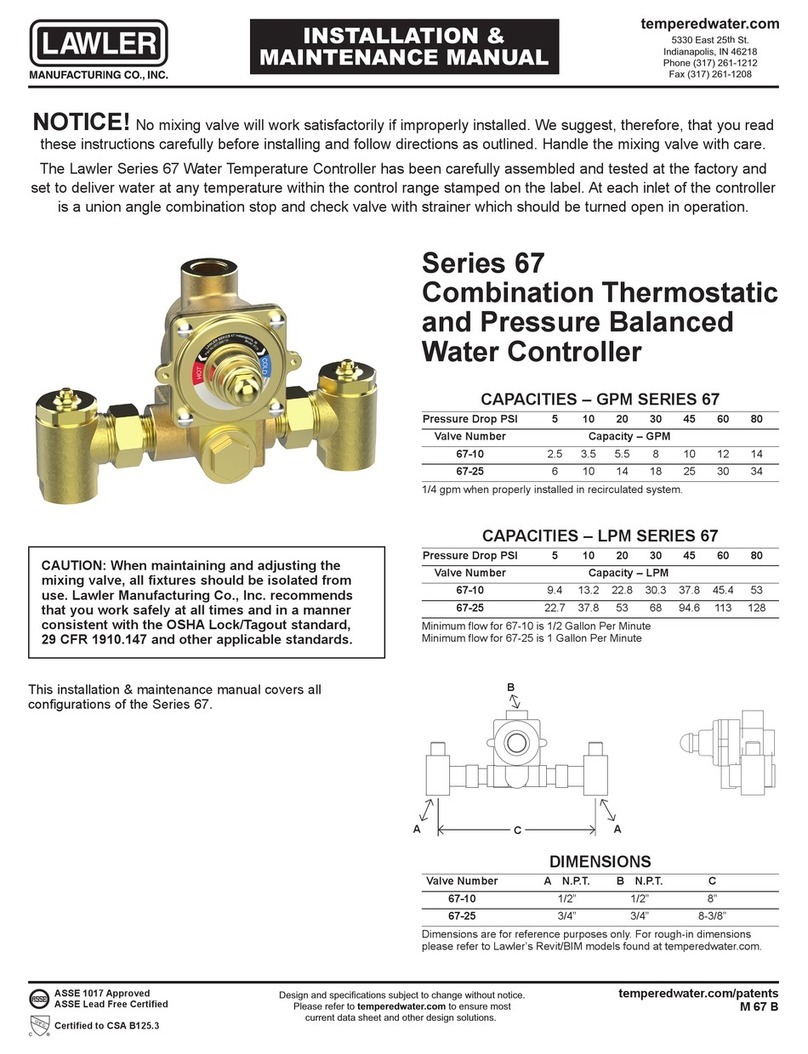

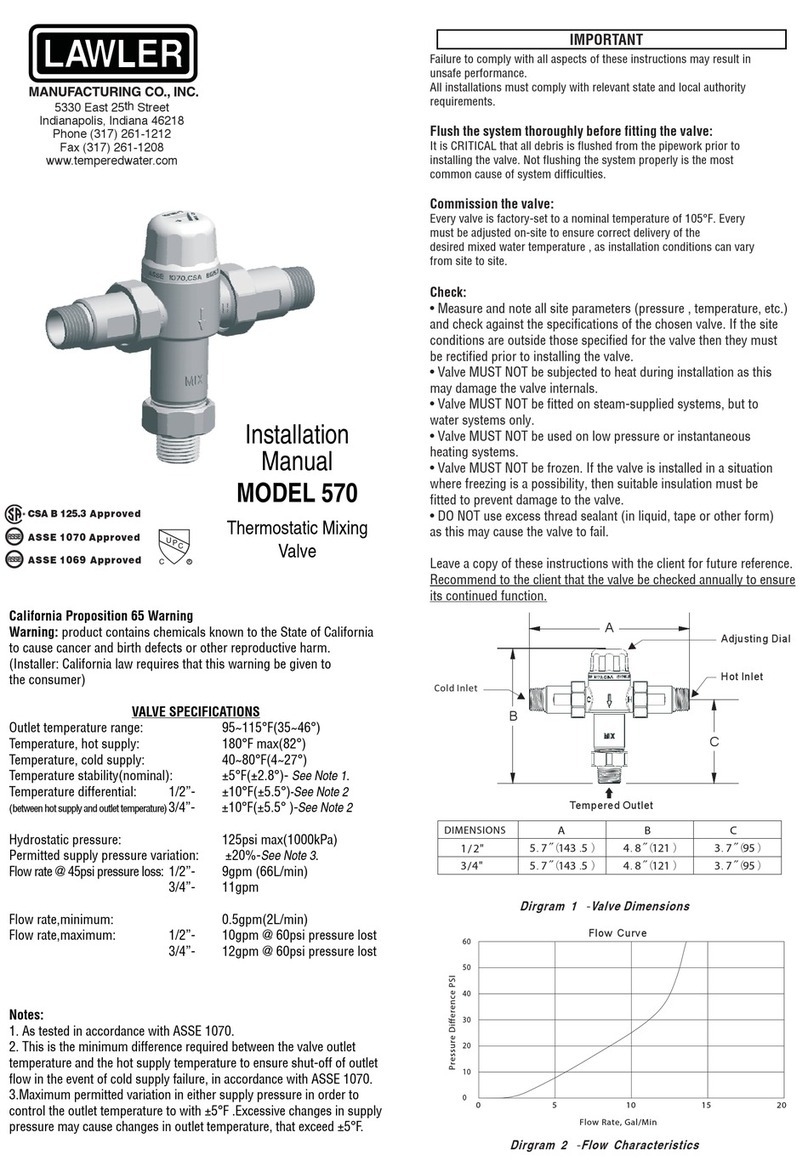

Mixing valve

Valve is carefully assembled and tested at the factory and

set to deliver water at any temperature between full cold

and 115°F. Failure of the cold water supply will cause the

hot water seat to close. The label on the valve cover is

marked “WARMER - COOLER,” so that the temperature set

screw can be set accordingly.

Stop and Check Valves

Each inlet of the mixing valve must have a screwdriver-

operated check valve. Both the cold and hot water stop

and check valves must be open at all times for proper

functioning of the valve.

The stop and check valves serve two purposes:

1. They prevent the hot or cold water from by-passing

through the mixing valve.

2. They provide convenient means to shut the supplies to

the mixer for cleaning or repairs.

Stop and checks are required whenever downstream shut

off devices are used.

Temperature Adjustment

The temperature of the hot water supplying the mixing

valve should be at least 15 degrees higher than maximum

required valve setting. Valves are normally set at factory

for 115°F maximum outlet temperature with 140°F inlet. If

readjustment is required, proceed as follows:

1. Remove outside acorn nut #2.

2. With narrow blade screwdriver, turn adjusting set screw

#5 clockwise to reduce the outlet temperature and

counterclockwise to increase outlet temperature. The

set screw should not be turned more than 1/2 turn at a

time without testing water temperature.

3. When temperature is correct, replace acorn nut.

Adjusting screw #5 may not be turned counter-clockwise

more than 1-1/2 turns.

CAUTION: It is not recommended to set maximum

outlet temperature above the applicable plumbing code.

Piping Instructions

Before installing the mixer, blow out all pipe lines to be sure

that no dirt, such as pipe chips, wicking or lead, can enter

the mixing valve. Valve inlets are marked hot and cold.

Piping must go to proper inlets.

Maintenance

The Lawler thermostatic mixer should be checked

periodically for proper operation and cleaning. See

“INSPECTION AND CLEANING VALVE.” To test mixing

valve for proper setting and operation—proceed as follows: