Lawler 3000 Instruction Manual

temperedwater.com

5330 East 25th St.

Indianapolis, IN 46218

Phone (317) 261-1212

Fax (317) 261-1208

INSTALLATION &

MAINTENANCE MANUAL

Design and specifications subject to change without notice.

Please refer to temperedwater.com to ensure most

current data sheet and other design solutions.

temperedwater.com/patents

M 3000 E

ASSE 1070 Approved

ASSE Lead Free Certied

Certied to CSA B125.3

NOTICE! No mixing valve will work satisfactorily if improperly installed. We suggest, therefore, that you read

these instructions carefully before installing and follow directions as outlined. Handle the mixing valve with care.

CAUTION: When maintaining and adjusting the

mixing valve, all xtures should be isolated from

use. Lawler Manufacturing Co., Inc. recommends

that you work safely at all times and in a manner

consistent with the OSHA Lock/Tagout standard,

29 CFR 1910.147 and other applicable standards.

This installation & maintenance manual covers all

congurations of the Model 3000.

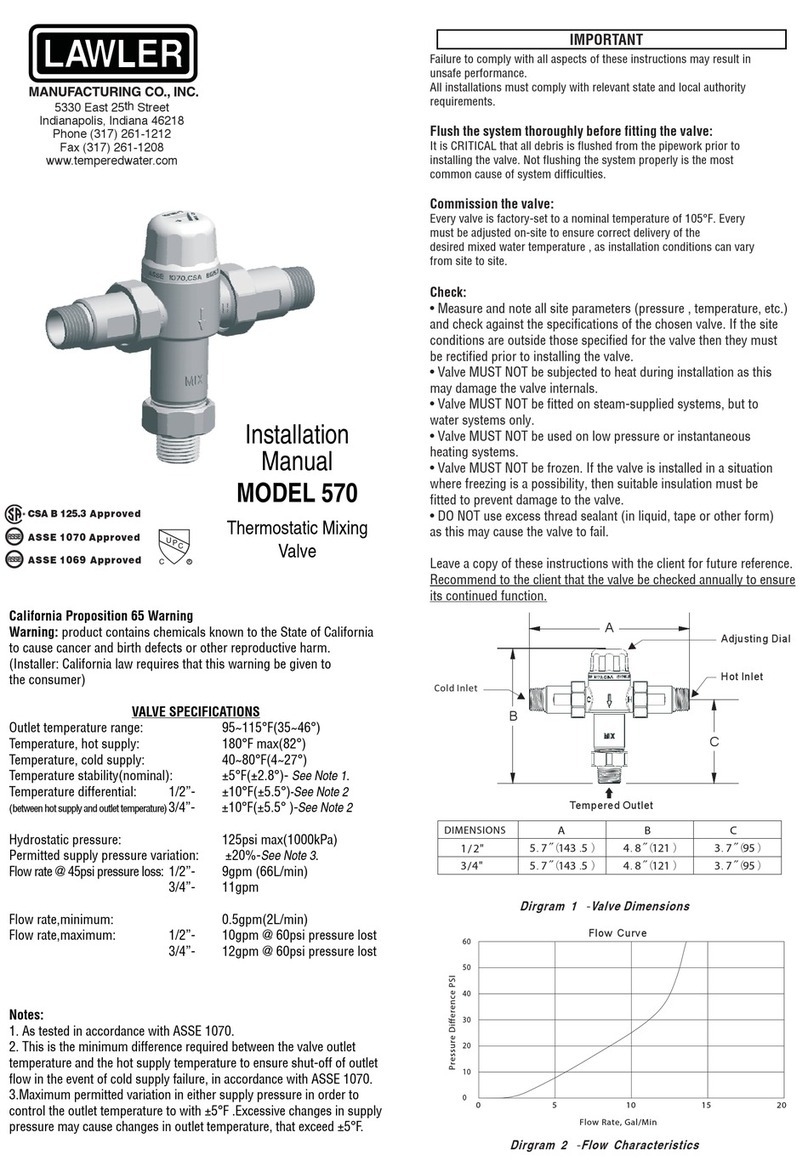

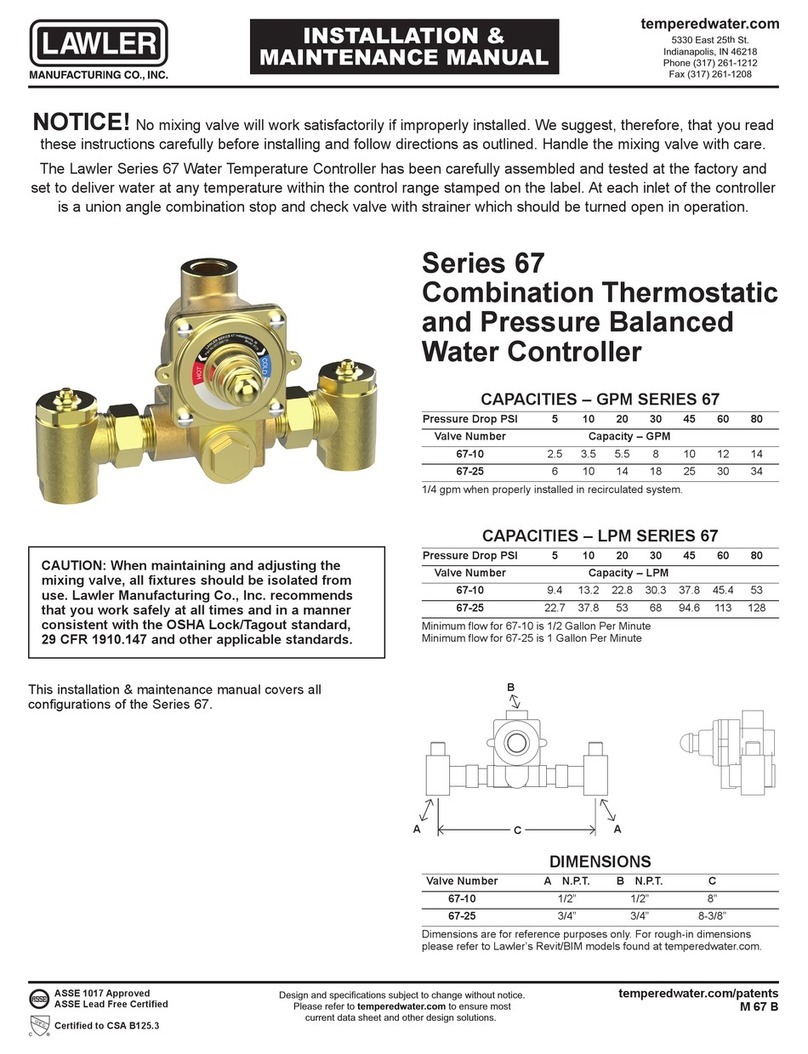

Model 3000

Thermostatic Shower Valve

3500 less stop & check valves

72047_3500-50_STD_DRW_NODIMS.pdf

B

A A

D

C E

DIMENSIONS

Valve Number A N.P.T. B N.P.T. C D E

3500 1/2” 1/2” 7-1/2” 5-1/8” 3-1/2”

Dimensions are for reference purposes only. For rough-in dimensions

please refer to Lawler’s Revit/BIM models found at temperedwater.com.

3800 less stop & check valves

73047_3800-50_STD_DRW_NODIMS.pdf

B

A A

C D

DIMENSIONS

Valve Number A N.P.T. B N.P.T. C D

3800 1/2” 1/2” 3-1/2” 4”

Dimensions are for reference purposes only. For rough-in dimensions

please refer to Lawler’s Revit/BIM models found at temperedwater.com.

3900 less stop & check valves

74147_3900-50_STD_DRW_NODIMS.pdf

B

A A

CD

DIMENSIONS

Valve Number A N.P.T. B N.P.T. C D

3900 1/2” 1/2” 10-1/2” 5-1/2”

Dimensions are for reference purposes only. For rough-in dimensions

please refer to Lawler’s Revit/BIM models found at temperedwater.com.

Checking Mixing Valve

1. Check movement of handle. Handle must move freely

from HOT to SHUT positions. If necessary, remove

handle and reposition so that the handle pointer aligns

properly.

2. CHECKING COLD WATER SHUT-OFF. Shut off hot

supply keeping cold supply open. Now move mixing

valve handle 1/2 turn counterclockwise.

A full volume of cold water should pass through valve.

Now move mixing valve handle as far as it will go

counterclockwise. The volume of cold water should be

reduced to a very small ow.

Failure of this to occur would indicate:

a. Piston #15 is stuck in one position. Unit has to be

cleaned.

b. Valve spring #18 has lost its strength and must be

replaced.

c. Cold water is in excess of 80°F.

3. CHECKING HOT WATER SHUT-OFF. Open both the

hot and cold supplies to mixing valve. Place handle at

hottest position (turned all the way counterclockwise).

Water should ow through valve at 110°F. If not,

adjust valve as explained under “TEMPERATURE

ADJUSTMENT.”

Now shut off the cold water supply to the mixing valve.

A properly operating mixer will shut off the hot water

almost instantly with hot water temperature supplying

the mixing valve at least 15 degrees higher than

maximum setting.

Failure to do so would indicate:

a. Dirt between the hot seat #17 in liner #21 and

piston #15 prevents it from closing. Unit has to be

cleaned.

b. The piston #15 could be stuck so that it cannot

move because of scale or some other deposit in

water. Unit has to be cleaned.

c. The thermostat has lost its power and has to be

replaced with a new one.

d. On 3/4” valve only if hot water pressure is over

50.p.s.i., valve may have a slight drip.

4. If a mixing valve will not shut off completely when

handle is turned all the way clockwise check:

a. Cold seat #13, may be worn or dirty - clean or

replace.

b. Seat of liner #21 could be eroded or cut - replace

piston & liner.

If the handle is hard to turn, remove spindle #4 and polish

with steel wool and lubricate with water insoluble grease or

Vaseline. Check O-Ring for imbedded foreign matter.

Inspection and Cleaning Valve

Shut off hot and cold water supply to mixing valve. Set

mixing valve handle on maximum hot position. Remove

body screws #9. Turn mixing valve handle toward cold

position until it forces cover off valve body. The thermostat

can now be examined.

Mixing valve

Valve is carefully assembled and tested at the factory

and set to deliver water at any temperature between full

cold and 110°F. Failure of the cold water supply will cause

the hot water seat to close. The label on the valve cover

is marked “HOT - COLD,” so that the handle can be set

accordingly.

When unit is not being used turn the handle toward COLD

position fully to shut off all ow.

Stop and Check Valves

Each inlet of the mixing valve must have a screwdriver-

operated check valve. Both the cold and hot water stop

and check valves must be open at all times for proper

functioning of the valve.

The stop and check valves serve two purposes:

1. They prevent the hot or cold water from by-passing

through the mixing valve.

2. They provide convenient means to shut the supplies to

the mixer for cleaning or repairs.

Stop and checks are required whenever downstream shut

off devices are used.

Temperature Adjustment

The temperature of the hot water supplying the mixing

valve should be at least 15 degrees higher than maximum

required valve setting. Valves are normally set at factory

for 110°F maximum outlet temperature with 140°F inlet. If

readjustment is required, proceed as follows:

1. Remove handle screw.

2. With narrow blade screwdriver, turn adjusting screw

#5 clockwise to reduce maximum outlet temperature

and counterclockwise to increase maximum outlet

temperature. This must be done with valve handle in the

hot position, turned counter-clockwise. Screw should

not be turned more than 1/2 turn at a time without

testing water temperature.

3. When temperature is correct, replace handle screw.

Adjusting screw #5 may not be turned counter-clockwise

more than 1-1/2 turns.

CAUTION: It is not recommended to set maximum

outlet temperature above the applicable plumbing code.

Piping Instructions

Before installing the mixer, blow out all pipe lines to be sure

that no dirt, such as pipe chips, wicking or lead, can enter

the mixing valve. Valve inlets are marked hot and cold.

Piping must go to proper inlets.

Maintenance

The Lawler thermostatic mixer should be checked

periodically for proper operation and cleaning. See

“INSPECTION AND CLEANING VALVE.” To test mixing

valve for proper setting and operation—proceed as follows:

Checking the Thermostat

If cold seat #13 on thermostat is worn or deeply indented,

remove it and replace with a new one. If there is a question

as to the thermostat being good, hold thermostat under

cold water faucet and insert an eraser capped pencil into

the center of thermostat. Make a reference mark where

pencil protrudes from the thermostat. Now place the entire

thermostat into hot water, approximately 125°F, for about

one minute. Remove thermostat from water, examine the

reference mark on pencil again. At this temperature, it

should extend out from former position about 1/8”. If it does

not, a new thermostat should be installed.

CAUTION: Extreme care should be exercised when

placing thermostat in and out of hot water.

Checking Piston and Liner

Remove piston assembly #15 from valve. Check the piston

assembly and liner #21 for cleanliness and excessive wear.

Check hot disc #17 for wear. Replace all worn parts.

Note: Liner #21can be removed with a:

9/32” hex wrench for low ow 1/2” valves, 3/8” hex wrench for

med & high ow 1/2” valves, 5/8” hex wrench for 3/4” valves.

Before reassembling the valve, thoroughly ush out with water.

Note: Piston Sub Assembly, consisting of parts #’s 16, 17,

18, 19 and 20, is factory pre-set with Liner #21, as a single

unit.

Use only genuine factory parts for replacement of seat

washers; thickness will affect the operation of the mixing

valve.

When in Need of Information

When writing the factory or one of its representatives

in regard to a mixing valve, be sure to give the number

appearing on the name plate fastened to the dome.

Repair Kit

Valves can be completely rebuilt in a matter of minutes

without removal from the line by installing a repair kit.

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

(Installer: California law requires that this warning

be given to the consumer.)

For more information: www.oehha.org/prop65

Thermostatic Shower Valve Cut-away

6

9

26

10

5

8

12

15

25

19

17

16

20

22

14

21

18

11

27

3

2

13

Recesso cutaway

Item Description Contains Part No.

A Complete Repair Kit 11-12-15-18-21+B 79850-00

B O-Ring & Gasket Kit 6-10-13-14-17-22-23-24-27 79959-00

C Piston & Liner Assembly 14-15-21 72014-11

E Cover & Spindle Assembly See page 4

F Thermostat Assembly 10-11 71870-11

H Dialplate Assembly See page 4

Must specify capacity and nish of valve. Parts shown under 1/2” are for 1-5 GPM.

All parts shown are for Plain Bronze nish.

Repair Kits and Assemblies

GUARANTEE

We guarantee the Lawler Mixing Valve to be free from defects in workmanship and material, and for

a period of one year from date of purchase, will replace any parts found by us to be defective. We will

not be held responsible, however, for any labor incidental to, or for any damages caused by defective

material. Each mixing valve is thoroughly inspected and tested under actual conditions at our factory.

Repair Kits for Inlet Stop & Checks

NOTE:* Components are not included in repair kit.

Item Description

1 Bonnet

2 Packer

3 Washer

4 Stem

5 Spring

6 Nose

7 Washer

*8 Body

123 4567 8

Kit I

1/2” Angled Stop & Check with Strainer

Part No. 70484-00

Repair Kit 79922-02

Item Description

1 Adjustment Stem

2 O-Ring Seal

*3 Bonnet

4 Spring

*5 Strainer Plug

6 O-Ring Gasket

7 Strainer

8 Strainer Disc Holder

*9A Body (Right Hand)

*9B Body (Left Hand)

10 O-Ring Disc

Kit J

1/2” Stop & Check

Part No. 6839-01

Repair Kit 79905-02

4

10

1

3

2

8

5

7

6

9

Covers

Kit H Kit E

Face Plate Face Plate Assembly Number Cover and Spindle

Series 3500 71985-00 71983-11

Series 3800 71985-04 71983-11

Recesso Conversion Kit to 71982-11 71982-11

Model 3800 PN 72910-10

Series 3900 74985-00 71982-41

WARM COLD

HOT SHUT

WARM COLD

HOT SHUT

WARM COLD

HOT SHUT

WARM COLD

HOT SHUT

WARM COLD

HOTSHUT

This manual suits for next models

3

Other Lawler Control Unit manuals

Lawler

Lawler 61 Series Instruction Manual

Lawler

Lawler 310 Instruction Manual

Lawler

Lawler 67 Series Instruction Manual

Lawler

Lawler 802 Instruction Manual

Lawler

Lawler NEPTUNE EMX 075 Instruction Manual

Lawler

Lawler 911 Instruction Manual

Lawler

Lawler 410 Instruction Manual

Lawler

Lawler 911E Instruction Manual

Lawler

Lawler 803 Instruction Manual

Lawler

Lawler 911 E/F Series User manual