(2)

Testing the Mixing Valve

The mixing valve and the emergency fixtures it serves

should be tested weekly for proper operation.

Valve temperature test procedure is as follows:

1. Activate eye wash fixture to observe and record

the temperature of the dial thermometer. If the

temperature of the thermometer is not correct,

readjust the mixing valve according to the section

“Setting the Mixing Valve”.

2. Observe the flow from the emergency fixtures to

ensure an adequate flow of water.

In addition to testing for proper temperature, the cold

water by-pass and hot water shut down features of

the mixing valve should be tested weekly.

The test procedure is as follows:

1. Test valve temperature as described in Step 1

and Step 2 above.

2. Shut off the hot water supply to the mixing valve.

Observe the outlet flow from the emergency fix-

tures to ensure an adequate flow of cold water.

A slight drop in flow may occur after shutting

down the hot water supply to the mixing valve;

however, the drop should be minimal and for a

short duration.

3. Open the hot water supply to the mixing valve.

The thermometer should return to the set tem-

perature.

4. Shut off the cold water supply to the mixing valve.

The flow of water should shut down rapidly.

5. Open the cold water supply. The thermometer

should return to the set temperature.

Note: The thermometer should be checked at least

every six months.

Replacing the Thermostat Element

The thermostat replacement procedure is as follows:

1. Shut off the hot water supply and cold water

supply to the mixing valve.

2. Remove the four cover screws (#9) and remove

the front cover (#26) of the valve.

3. Remove thermostat (#11) from the valve body.

No special tools are necessary.

4. Insert a dowel rod, pencil (eraser-end), or narrow

pen into the open end of the thermostat. Push on

the dowel rod with your hand. If the thermostat

feels spongy or springy, the thermostat has lost

its charge. If the thermostat feels solid or hard,

the thermostat is good and operable.

5. Be sure that the stainless steel piston (#15)

moves freely up and down within the liner (#21).

Lime or calcium buildup should be cleaned with

vinegar, green scotch pad, or fine emery cloth.

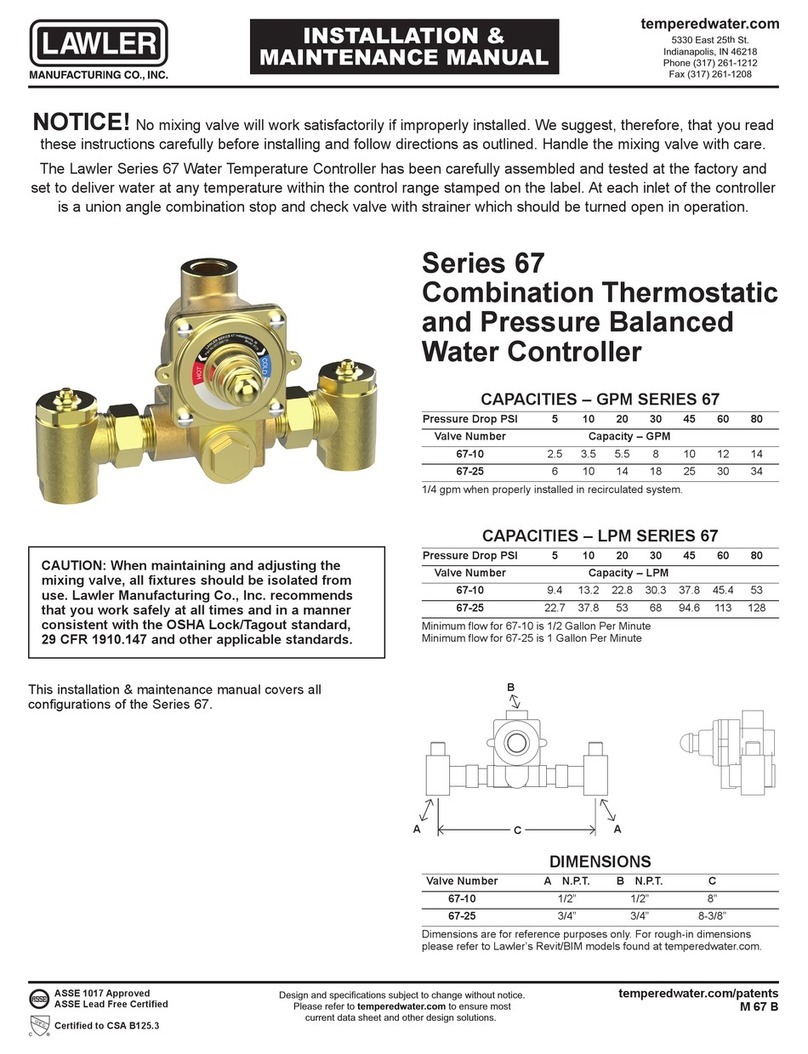

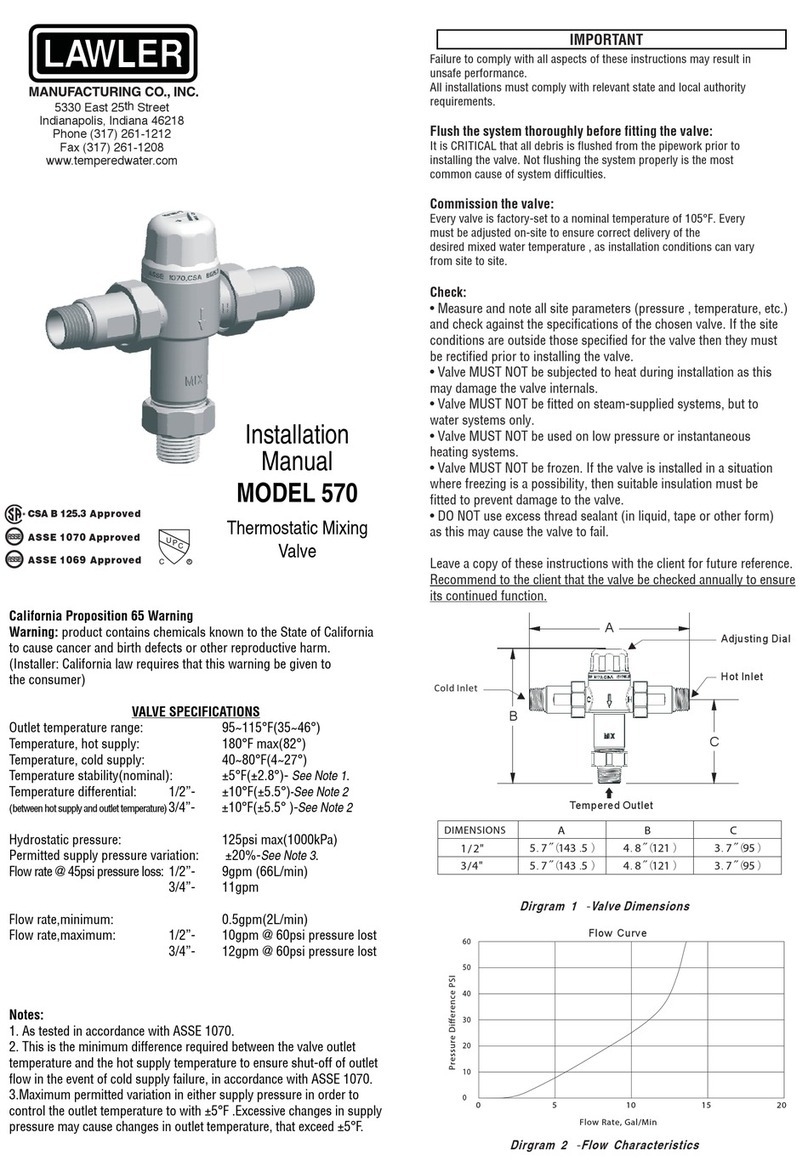

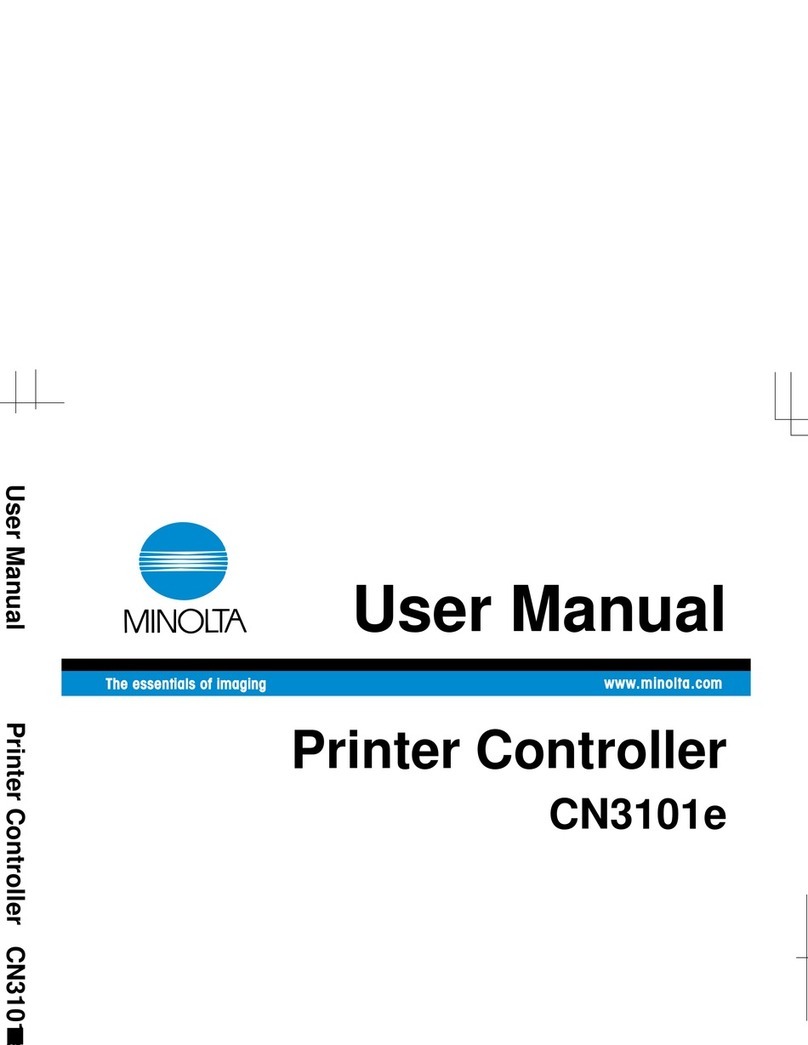

DIMENSIONS: 1/2″inlets & outlets

Valve

Number A B C

911E/F 9″4″8″

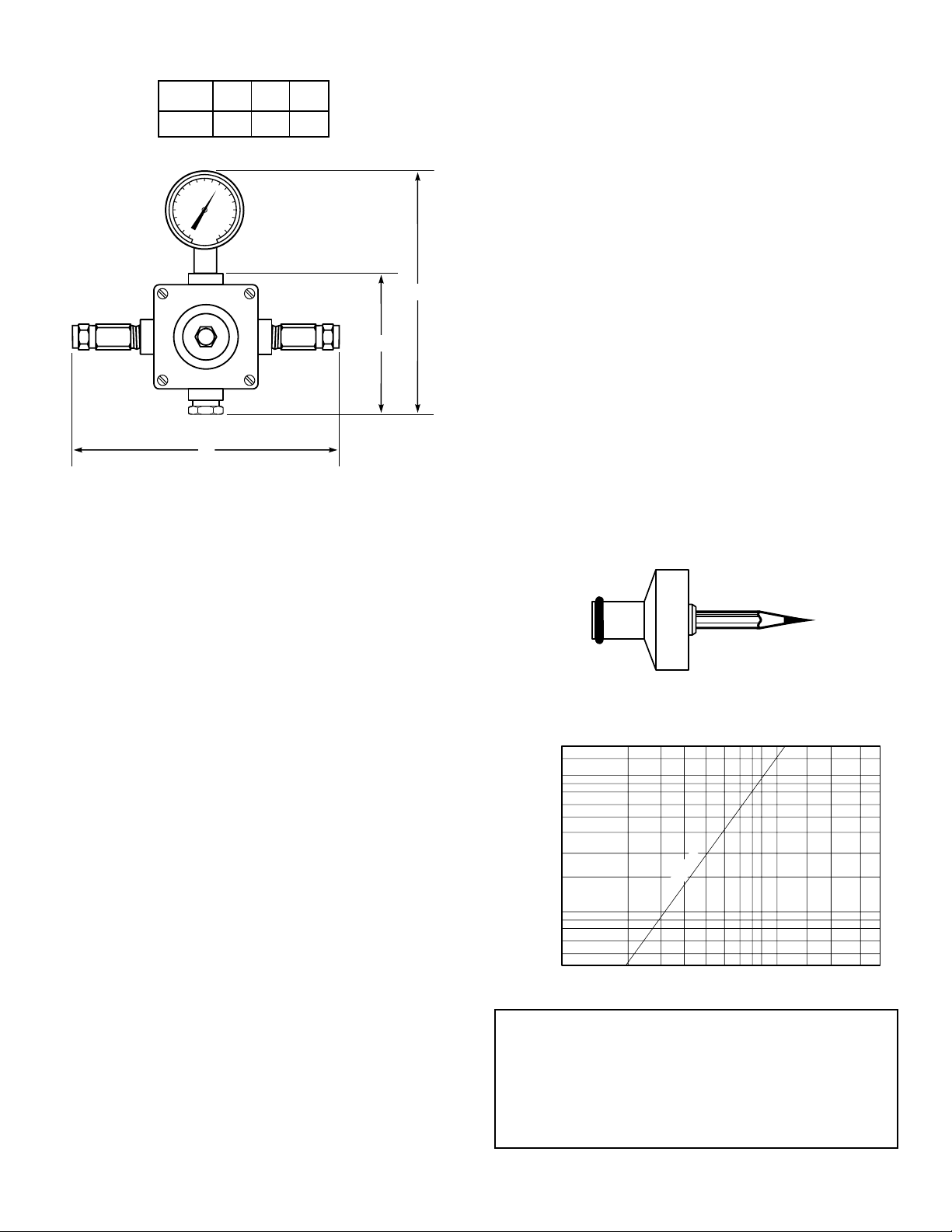

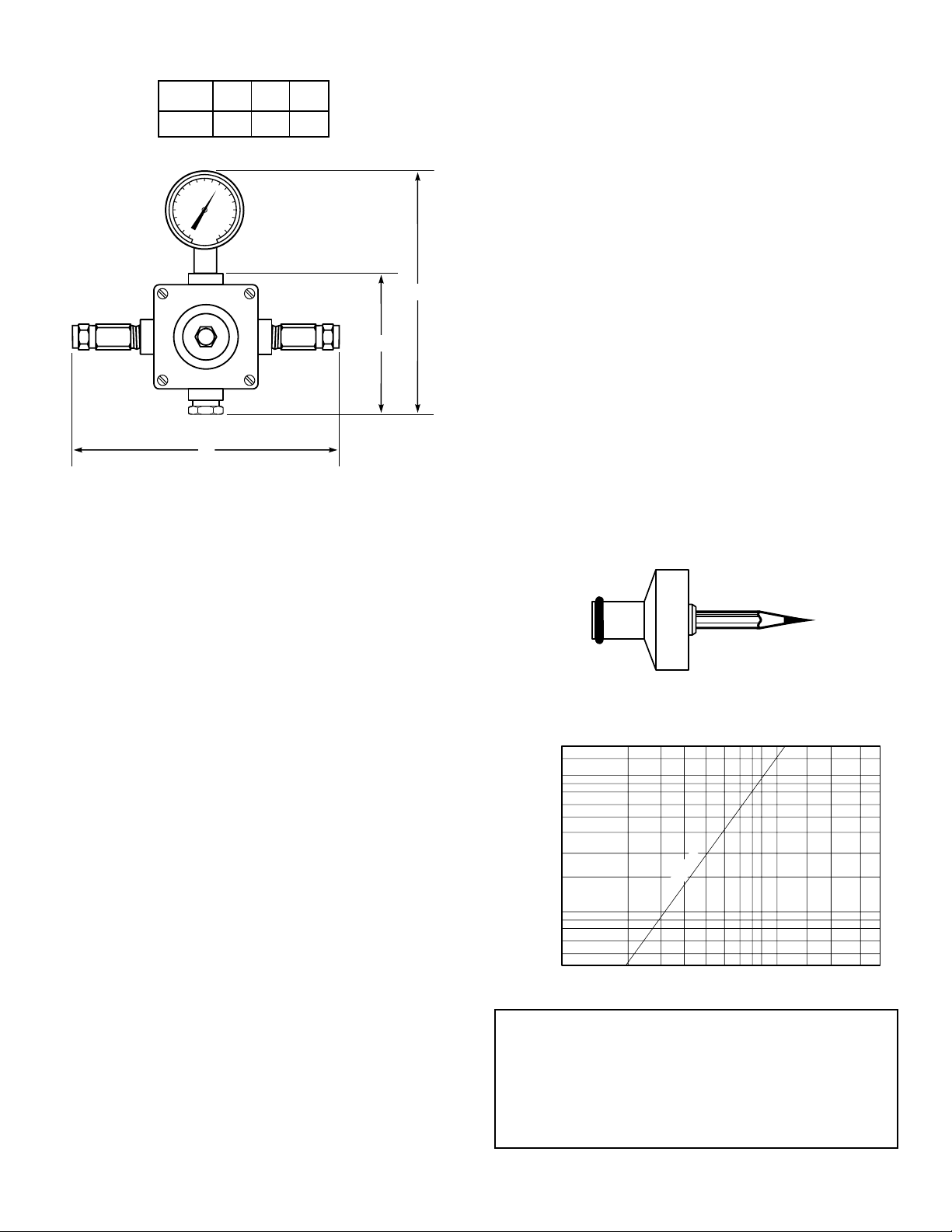

PRESSURE DROP, POUNDS PER SQUARE INCH

FLOW OF WATER, GALLONS PER MINUTE

70

5

60

40

35

30

25

20

15

8

7

6

9

10

45

50

1 2 3 4 5 6 7 8 9 10 15 20 30 35

1/2

″

MED

CAPACITY OF TYPE 911E/F

THERMOSTATIC MIXING VALVE

FOR EMERGENCY SHO

W

ERS

30

40

50

60

70 80

90

110

120

130

A

B

C

Note: Gallon per minute ratings may vary de-

pending upon incoming water temperatures and

pressures. Hot and cold water inlet pressures

must be equal.

Provisions shall be made to thermally isolate

the valve.