in ow may occur after shutting down the hot water

supply to the mixing valve; however, the drop should be

minimal and for a short duration.

3. Open the hot water supply to the mixing valve.

Thermometers T1 and T2 should return to their set

temperatures and T3 to the proper outlet temperature.

4. Shut off the cold water supply to the mixing valve. The

ow of water should shut down rapidly.

5. Open the cold water supply. Thermometers T1 and T2

should return to their set temperatures and T3 to the

proper outlet temperature.

Operating Principle

The Model 911 Mixing Valve is made of two independent

thermostats housed in a single lead free brass casting.

The twin thermostatic cartridges respond independently

to incoming hot and cold water temperatures and provide

backup protection against element failure. If one element

fails, the other should continue to function properly. If

only one element is operating the valve will experience a

decrease in outlet temperature (T3). For this reason the

Model 911 Valve requires testing and maintenance on a

regular basis. In the event of element failure, the cartridge

will provide full cold water ow. The resulting temperature

difference between the two valves will be reected by T1

and T2.

Thermometers T1, T2, and T3 should be checked at least

every six months.

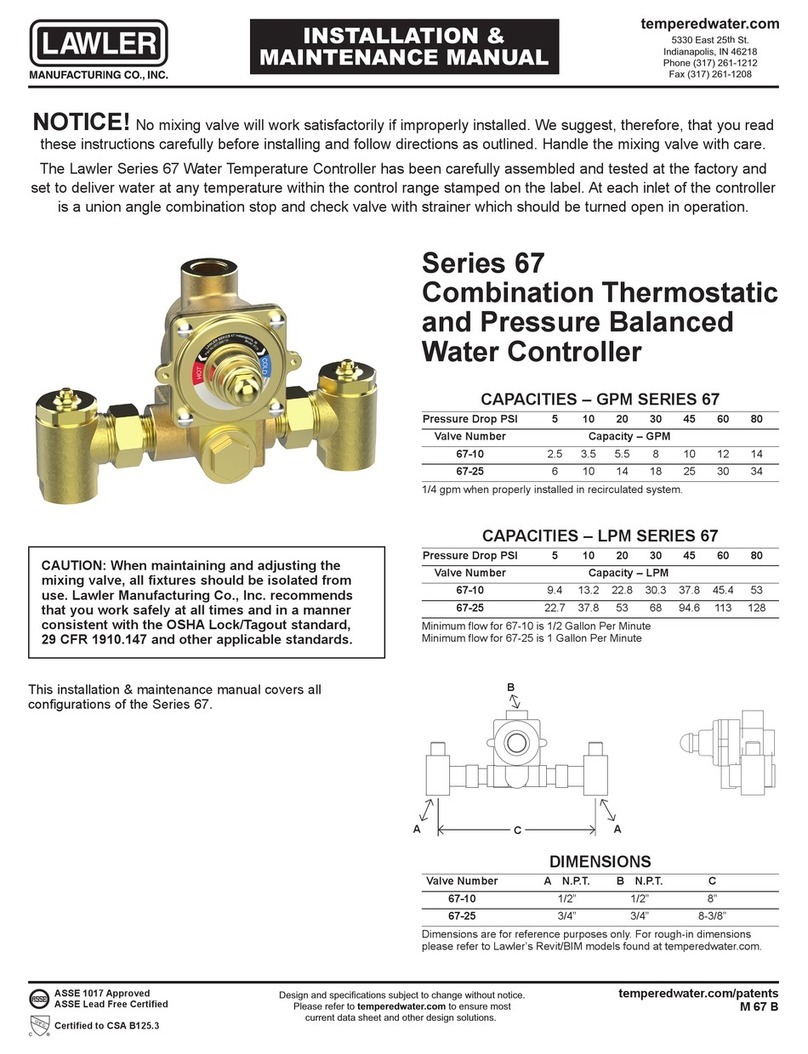

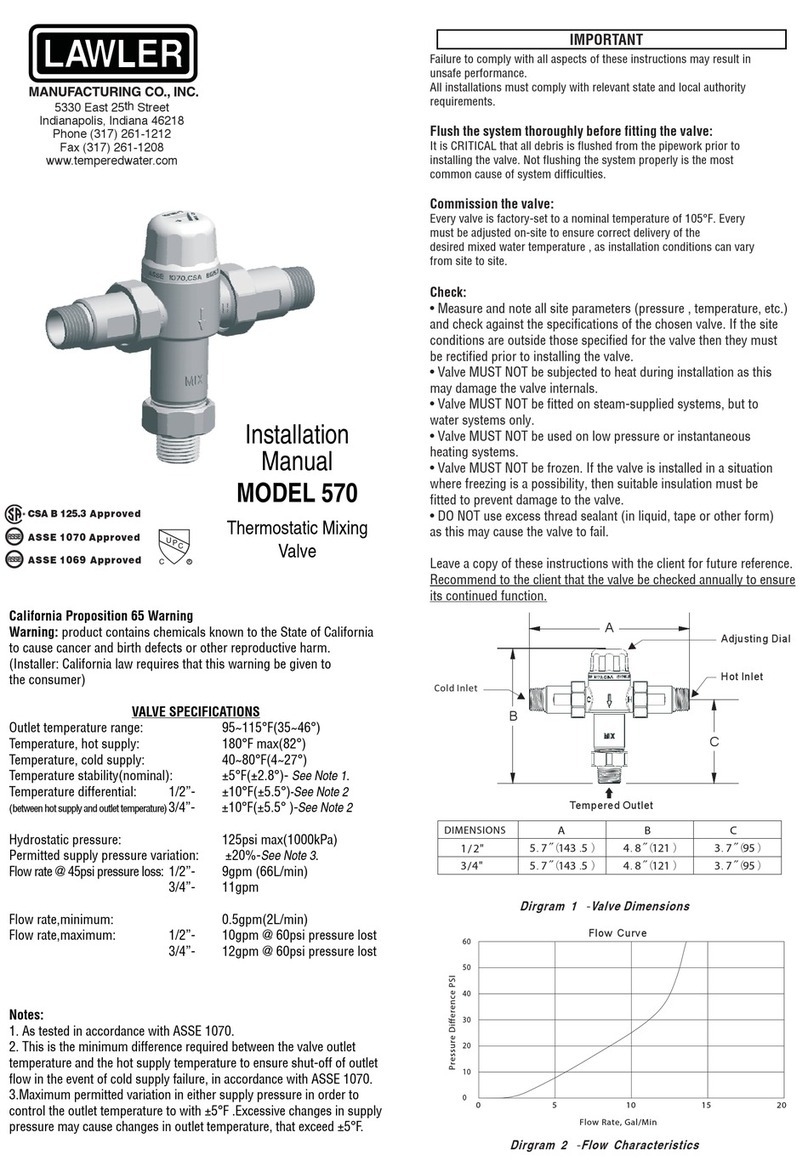

Installation

After installing the mixing valve, be sure to ush the system

thoroughly. Lawler recommends isolation and check valves

for proper maintenance.

Testing the Mixing Valve

The mixing valve and the emergency xtures it serves

should be tested weekly for proper operation.

Valve temperature test procedure is as follows:

1. Activate shower xtures to observe and record the

temperature of the thermometers T1, T2, and T3.

The valve is functioning properly if the T1 and T2

temperatures are equal and T3 is at the proper outlet

temperature. If the temperature of thermometers T1 and

T2 are not equal, readjust the mixing valve according to

the section “Setting the Mixing Valve.” Slight variations

between the valve set temperatures and the outlet

temperatures may occur.

2. Observe the ow from the emergency xtures to ensure

an adequate ow of water.

In addition to testing for proper temperature, the cold water

by-pass and hot water shut down features of the mixing

valve should be tested weekly.

The test procedure is as follows:

1. Test valve temperature as described in Step 1 and Step

2 above.

2. Shut off the hot water supply to the mixing valve.

Observe the outlet ow from the emergency xtures

to ensure an adequate ow of cold water. A slight drop

30

40

50

60

70 80

90

110

120

130

30

40

50

60

70 80

90

110

120

130 30

40

50

60

70 80

90

110

120

130

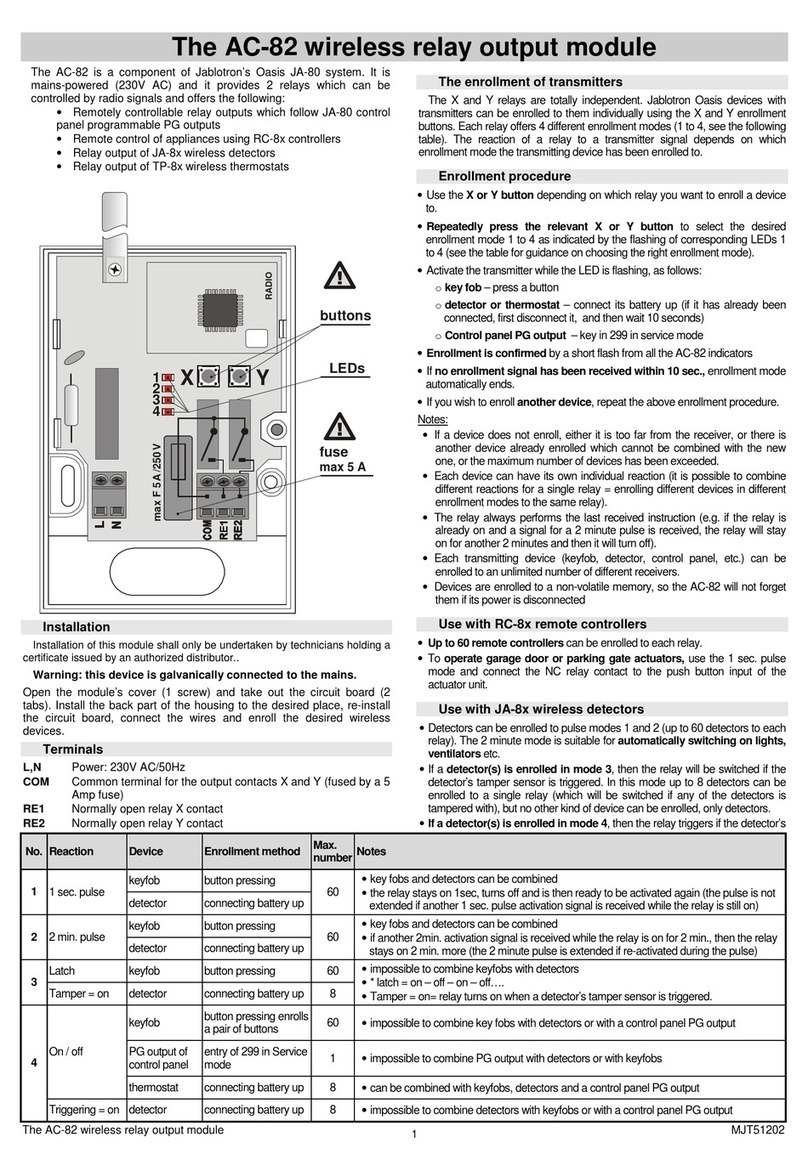

1″

4N.P. T.

N.P. T.

HOT

INLET

1″

4A

B

C

1

N.P. T. TEMPERED

OUTLET

1

4

1

T2

T3

T1

5330 East 25th Street

Indianapolis, Indiana 46218

Valve 2

(V2)

Valve 1

(V1)

Replacing a Thermostat Cartridge

The thermostat replacement procedure is as follows:

1. Shut off the hot water supply and cold water supply to

the mixing valve.

2. Unscrew valve V1 or V2 (depending on which valve

is not operating properly) and install a new thermostat

cartridge assembly.

3. Open the hot water supply and the cold water supply

to the mixing valve. Check the temperature to see if

the replacement cartridge is operating correctly. If the

temperature requires adjustment refer to the section

“Setting the Mixing Valve.”

20

40

60

80 100120

14 0

16 0

18 0

200

0

Cartridge Kit

Part Number 8334-50

Thermometer

Part Number 6679-00