ALL-IN-ONE™INSTRUCTION MANUAL

5

4.2 Tighten the clamp underneath the concrete slab unl the base is ghtly mounted to the concrete slab.

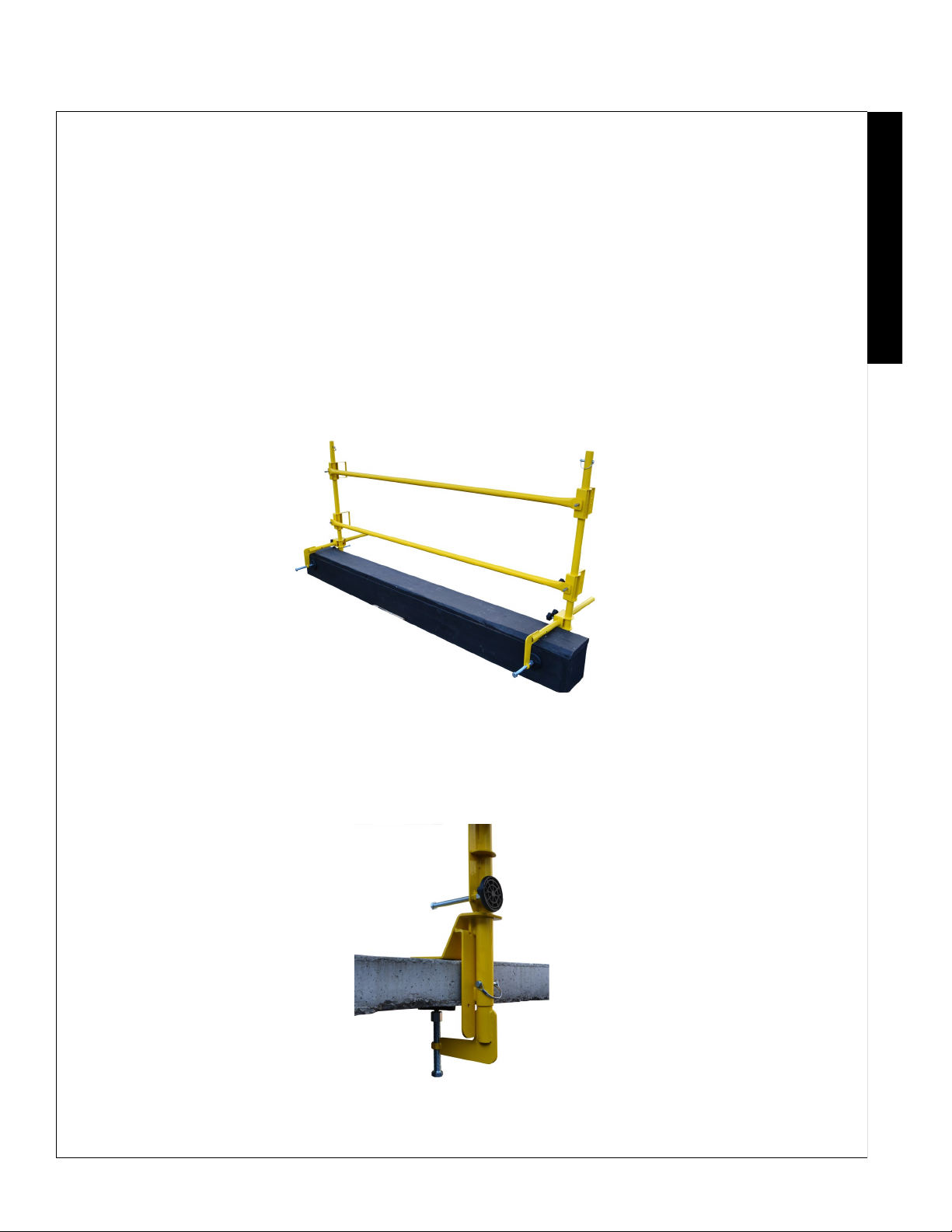

5.0 Installing the Horizontal Rails

5.1 All-In-OneTM can be used with metal RaptorRailTM rails or lumber rails.

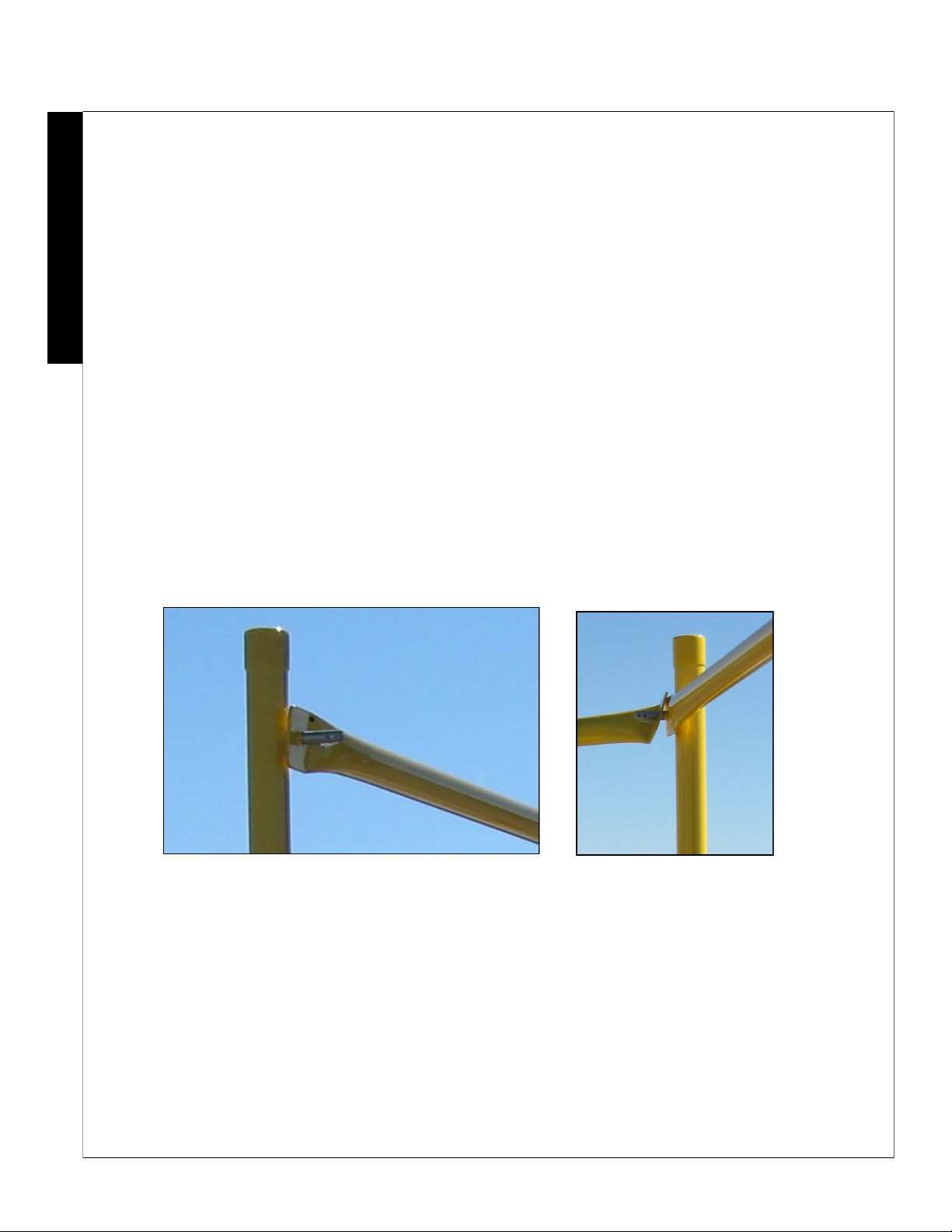

5.2 To install using metal RaptorRailTM Rails, install the bases the width of the rail (8’, 10’, or adjustable). Loosen the rail

brackets on the vercal posts and turn the brackets so that the railing drop-lock pins are facing in toward the working

surface. Then ghten the brackets using the ghtening knobs so that the top rail is 42” +/- 3” above the walking/

working level. Lastly, slide the metal RaptorRailTM onto the droplock pins.

5.3 To install using wood rails, cut the lumber no more than 9’ long. The lumber rail must overlap on either side of the posts

by 6”. The posts in a wood rail system must be spaced a maximum of 8’. Install the posts and bases at a maximum of 8’

apart. Loosen the rail brackets on the vercal posts and turn the brackets so that the wood brackets are facing in to-

ward the working surface. Then ghten the brackets using the ghtening knobs so that the top rail is 42” +/- 3” above

the walking/working level. Slide the wooden rails into the brackets and secure using at least two wood screws.

6.0 General Installaon Tips

6.1 Aer aaching the corner, begin seng up the addional bases at approximately 10 foot intervals. A good technique to

ensure the best possible t is to connect a top rail to an already mounted/xed base, set up the approximate posion of

the next base, connect the rail to the top pin, and set up the base in a vercal posion. Then connect the mid-rail.

When the post/base is connected and veried to be in a fully upright or vercal posion, aach the base either using

mounng screws or, if using the oponal parapet clamps, ghten the clamp.

6.2 Connue this process unl the railing system is complete, or unl the next corner locaon. At the corner, place the two

corner post/bases no less than 18" and no more than 27" from the actual corner. If the distance between your last post/

base and the corner post/base just installed is less than 10 feet, use the adjustable rails for opmum t.

7.0 Applicaons

7.1 The All-In-OneTM is to be used as a railing system for roofs and intermediate level oors. The All-In-OneTM may be used

where worker mobility and fall protecon are required.

7.2 The All-In-OneTM should be used as a part of a complete fall protecon system plan.

E

N

G

L

I

S

H