Safety Bull™ – 3

1. UK – SAFETYBULL INSPECTION AND

MAINTENANCE LOG

3.

Inspection date

8.

11.

13.

1. DK – SAFETY BULL EFTERSYNS- OG

VEDLIGEHOLDELSESLOG

3. Safety Bull serie

Safety Bull model

8.

Vogndele

11.

Svejset forbindelse

13. -

1. DE – INSPEKTIONS- UND

WARTUNGSPROTOKOLL SAFETY BULL

füllen Sie es vor jeder Benutzung aus

und archivieren Sie es.

3. Serie Safety Bull

8.

Wartung durchgeführt

Wagenteile insgesamt

11. Genehmigt durch

13. Zurrringe Sicherheitsleine und

1. PL – DZIENNIK KONTROLI I

KONSERWACJI SAFETY BULL

w swoich rejestrach.

3.

8.

11. Zatwierdzone przez

13. -

1. SE – INSPEKTIONS- OCH

SÄKERHETSLOGG FÖR SAFETYBULL

varje användning och spara den.

3.

8.

Övergripande vagndelar

11.

Svetsade anslutningar

13.

1. NO – SAFETY BULL INSPEKSJONS- OG

VEDLIKEHOLDSLOGG

sammen med papirene dine.

3.

Inspisert element notert

8.

Generelle vogndeler

11.

13.

1. FI – SAFETY BULLIN TARKISTUS- JA

KUNNOSAPITOLOKI

3. Safety Bullin sarjanumero

Safety Bullin malli

8.

11.

13.

1. CZ – PROTOKOL KONTROLY A ÚDRŽBY

ZAŘÍZENÍ SAFETYBULL

záznamech.

3.

8.

11. Schválil

13.

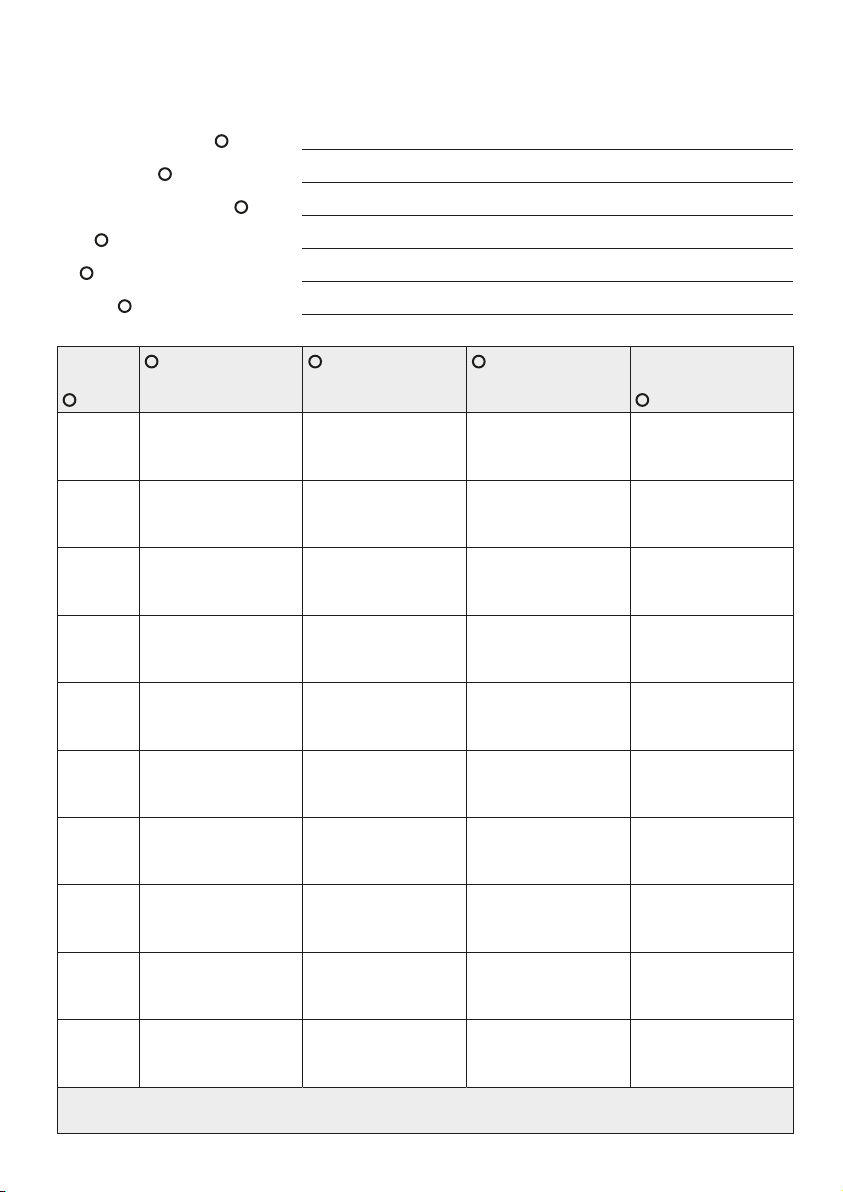

1. EL - ΑΡΧΕΙΟ ΚΑΤΑΓΡΑΦΗΣ

ΕΠΙΘΕΩΡΗΣΗΣ ΚΑΙ ΣΥΝΤΗΡΗΣΗΣ

SAFETY BULL

2. Αντιγράψτε αυτό το αρχείο κατα-

γραφής, συμπληρώνετέ το πριν

από κάθε χρήση και διατηρείτε το

στα αρχεία σας.

3. Αριθμός σειράς Safety Bull

4. Αριθμός μοντέλου Safety Bull

5. Ημερομηνία αγοράς

6. Ημερομηνία επιθεώρησης

7. Σημειώθηκε στοιχείο επιθεώ-

ρησης

8. Απαιτείται διορθωτική ενέργεια

9. Πραγματοποιήθηκε συντήρηση

10. Γενικά εξαρτήματα καλαθιού

11. Εγκρίθηκε από

12. Συγκολλημένη σύνδεση

13. Δακτύλιοι πρόσδεσης και

δακτύλιοι D ανύψωσης γραμμής

ζωής ασφάλειας

14. Καλώδια

15. Ένδειξη πτώσης

16. Γενική διάβρωση καλαθιού

1. ES - REGISTRO DE INSPECCIÓN Y

MANTENIMIENTO DEL SAFETY BULL

de cada uso y guárdelo en sus

archivos.

3.

8.

11.

Juntas de soldadura

13.

elevadores

1. FR - REGISTRE D’INSPECTION ET

D’ENTRETIEN DE SAFETY BULL

remplir avant chaque utilisation et le

conserver dans vos dossiers.

3. Série Safety Bull

8.

11.

13.

levage de sécurité de la ligne de vie

Indicateur de chute

1. IT - REGISTRO ISPEZIONI E

MANUTENZIONI SAFETY BULL

compilarlo prima di ogni uso e

conservarlo nei propri archivi.

3.

Voce ispezione annotata

8.

11.

13.

Indicatore di caduta

1. NL – INSPECTIE- EN

ONDERHOUDSLOGBOEK VOOR

SAFETYBULL

administratie.

3. Serienummer Safety Bull

Inspectiepunt genoteerd

8.

11.

13.

Valindicator

1. RO – JURNAL DE INSPECȚIE ȘI

ÎNTREȚINERE SAFETYBULL

dvs.

3.

8.

11.

13.

1. RU — ЖУРНАЛ ПРОВЕРКИ И

ТЕХОБСЛУЖИВАНИЯ УСТРОЙСТВА

SAFETY BULL

2. Скопируйте этот журнал,

заполняйте его перед каждым

использованием и храните в

своих записях.

3. Серийный номер устройства

Safety Bull

4. Модель устройства Safety Bull

5. Дата покупки

6. Дата проверки

7. Пункт проверки с примечанием

8. Необходимое корректирующее

действие

9. Проведенное техобслуживание

10. Все детали тележки

11. Утвердил

12. Сварное соединение

13. Кольца для пристегивания стра-

ховочного пояса и D-образные

кольца для подъема

14. Кабели

15. Индикатор падения

16. Коррозия всех частей тележки

1. SK – PROTOKOL KONTROLY A ÚDRŽBY

ZARIADENIA SAFETY BULL

3.

8.

11. Schválil

13.

1. BS – SAFETY BULL DNEVNIK INSPEKCE

I ODRŽAVANJA

3.

Safety Bull model

8.

11.

Vareni spoj

13.

Sajle

1. TR – SAFETY BULL DENETİM VE BAKIM

GÜNLÜĞÜ

3.

8.

11.

13.