Lee Reloading products are guaranteed not to wear out or break from

normal use for two full years, or they will be repaired or replaced at no

charge if returned to the factory. Any Lee product of current manufacture,

regardless of age or condition, will be reconditioned to new, including a

new guarantee, if returned to the factory with payment equal to half the

current retail price.

THE LEE GUARANTEE

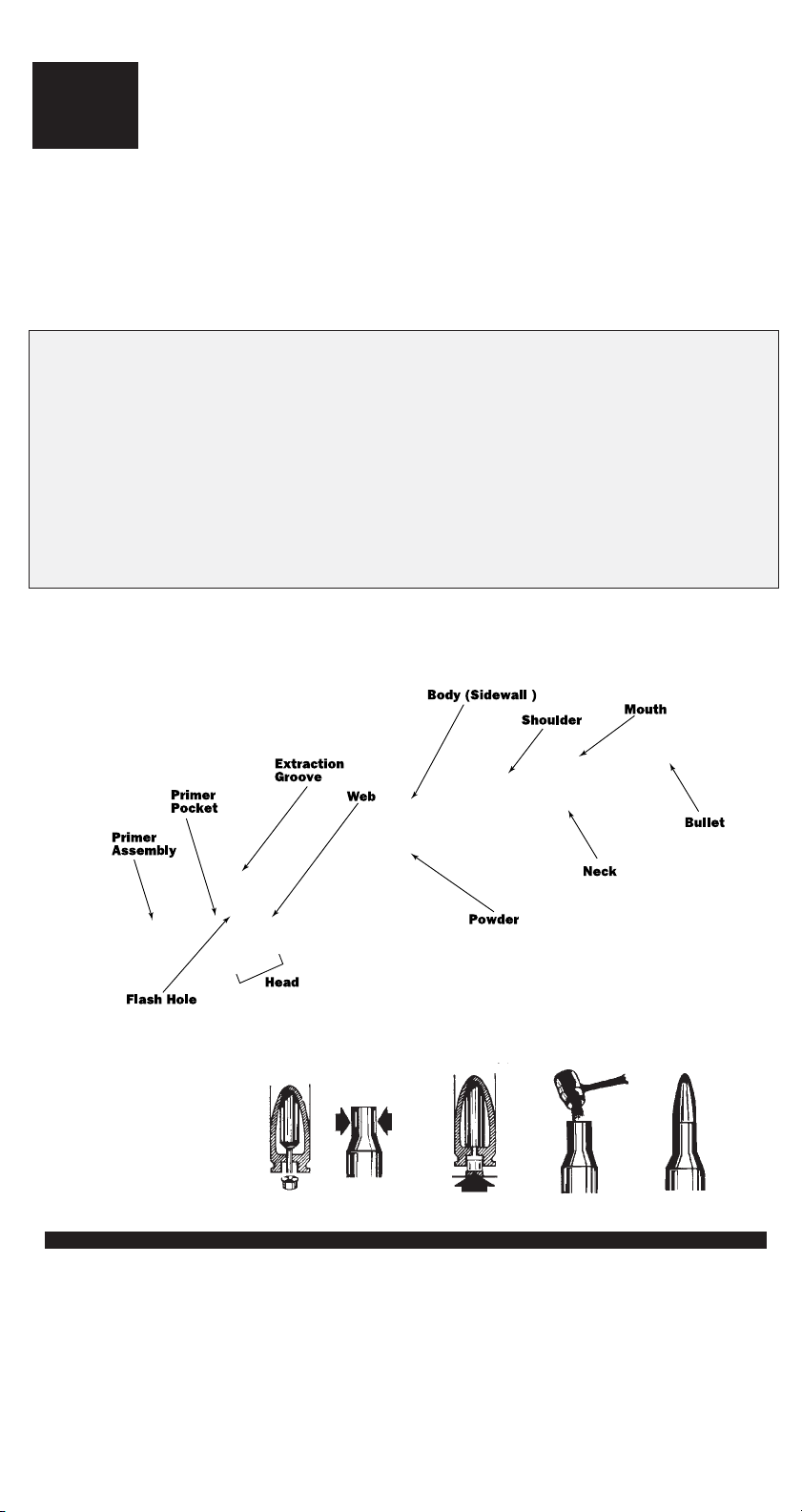

CASES

The easiest and best way of getting cases is to simply save

those from your factory loaded rounds. New and used cases

can also be purchased. Cases must be clean and safe. Do not

use cases that have cracks or splits. If they have been used

more than twice, they should be checked to see that none of

them have become too long for safe use. The easiest way is

to trim them is with a Lee Case Trimmer. This automatically

cuts them to the correct length and no gauging or measuring

is needed. Afer trimming, be sure to chamfer both the inside

and outside of the case. A Lee Chamfer Tool works best, but

it can be done with a pocket knife.

Straight sided cases, such as those used by most hand-

guns, are loaded with a 3–die set.

MILITARY CASES

Used military cases are readily available at low cost. Usually,

these have primers that are crimped in place. This is to pre-

vent the primer from coming loose in automatic weapons and

jamming the action at an inopportune time. The crimp must

be removed before repriming. This can be done with a primer

pocket reamer or swaging tool. Even a Lee Chamfer Tool can

be used to ream the crimp.

POWDER

Powder is usually classified as smokeless and black powder.

There is also Pyrodex, which is a substitue for black powder.

We will be using only smokeless powder for reloading.

Each set of Lee Dies is supplied with powder mea-

sure and charge table with a generous selection of loads.

Additional load data is available from all the powder manu-

facturers and bullet makers. This is excellent information

and should be followed exactly.

Dierent powders are available to do dierent jobs.

Bullets having a high sectional density ( long length in rela-

tion to their diameter) require a slow burning powder. This

permits sustained peak pressure to gain maximum accelera-

tion within working pressure limits.

Short, light bullets use quicker burning powder for

complete combustion within the barrel. A wide selection of

powder is readily available. Powders should always be stored

in their original containers. While smokeless powder is not

an explosive and not as dangerous to handle as gasoline, it

would be foolish to handle it carelessly and store excessive

amounts. Follow the powder manufacturers’ recommendations

for storage and use.

PRIMERS

Rifle and pistol cartridges require dierent primers. Rifle

primers have a thick and stronger cup to withstand the

higher pressure. Pistol primers have a thinner cup for

easy detonation with a lighter hammer blow. Both rifle

and pistol primers are available in regular and magnum.

Use regular for all loads except if the load data specifies mag-

num primers.

Primers must always be stored in their original containers.

It is always a wise idea to wear safety or shooting glasses when

shooting or reloading.

BULLETS

Commercial rifle bullets usually have a sof lead core with a

copper jacket. Point shapes come in a variety of styles, but

usually have some sof lead exposed to properly mushroom

on impact.

The jackets serve a dual purpose: to control the bullet

expansion and act as a bearing surface for its high speed travel

down the bore. Some bullets have a crimping groove called a

cannelure. This groove must be seated almost entirely in the

case when crimping the case. The very end of the case mouth

is turned into this groove by the bullet seating die used in a

tubular magazine gun and most revolver ammunition.

Cast bullets are very popular with the handloader. These

are very economical to use and for all guns where the velocity

is less than 2,000 feet per second and can be as accurate as

jacketed bullets. They do not normally expand as well as sof

lead jacketed bullets on game. Therefore, it is poor economy to

use them for hunting.

CRIMPING

Ammunition loaded for hunting should always have the bul-

lets crimped in place, as should ammunition used in tubular

magazine and auto-loading rifles. It could ruin your hunt if a

bullet wedged in the chamber or pushed back into the case.

Best accuracy is usually obtained with crimped ammo as the

crimp has an eect on ignition, velocity, pressure and bal-

listic consistency. No die does a better job crimping than the

Lee Factory Crimp Die.

Cycle the press up and down.

If the turret does not stop in the correct

position—follow these instructions.

With the ram in the down position, place a

N-inch wrench on the index rod and hold

in position. Now rotate the turret into the

correct position. Never use a pliers as index

rod damage will occur.

ADJUSTING THE INDEX

TF 3567

Square Ratchet TP 2673 Square index rod

TF 3566 Auto Index clamp

FT 3570

8-32

x 11⁄2Phillips panhead

PARTS LIST FOR THE FOUR HOLE AUTO INDEX