5

This die may come with a silver Breech Lock Bushing installed.

(A) Install appropriate die and bushing onto Auto Drum powder measure.

(B) Insert assembly into position 2.

(C) Position a case under position 2 and raise to top of its stroke (hold

lever down).

(D) Rotate entire powder measure and die inward until the top of stroke

indicator nears the top of the slot in the casting.

Dispense position

Note: slider drop

tube should not

make contact with

top of slot

Position 3

This is an excellent positon for the optional Lee

Universal Expanding die when loading bottleneck

rifle cartridges.

Universal Case Expanding

Die # 90798

Position 2 = Powder Through Expanding Die or Rifle Charging Die

Position 3 = Universal Case Expanding Die

Position 1 = Full Length Sizer Die

sizing & depriming must be done in this station

Position 4 = Accessory

priming

position

This die may come with a red Breech Lock Bushing installed.

(A) Install die and bushing in tool head position 1.

(B) Raise the carrier to top of stroke. (Handle down and hold)

(C) Screw die into contact the shell plate.

(D) Release lever, screw in the die additional 1/3 turn further.

*Note* Using a 1/2” (13mm) wrench on the decapper clamp makes adjustment

easy.

EZ X Expander / Decapper

Breech Lock Bushing

Decapper Clamp

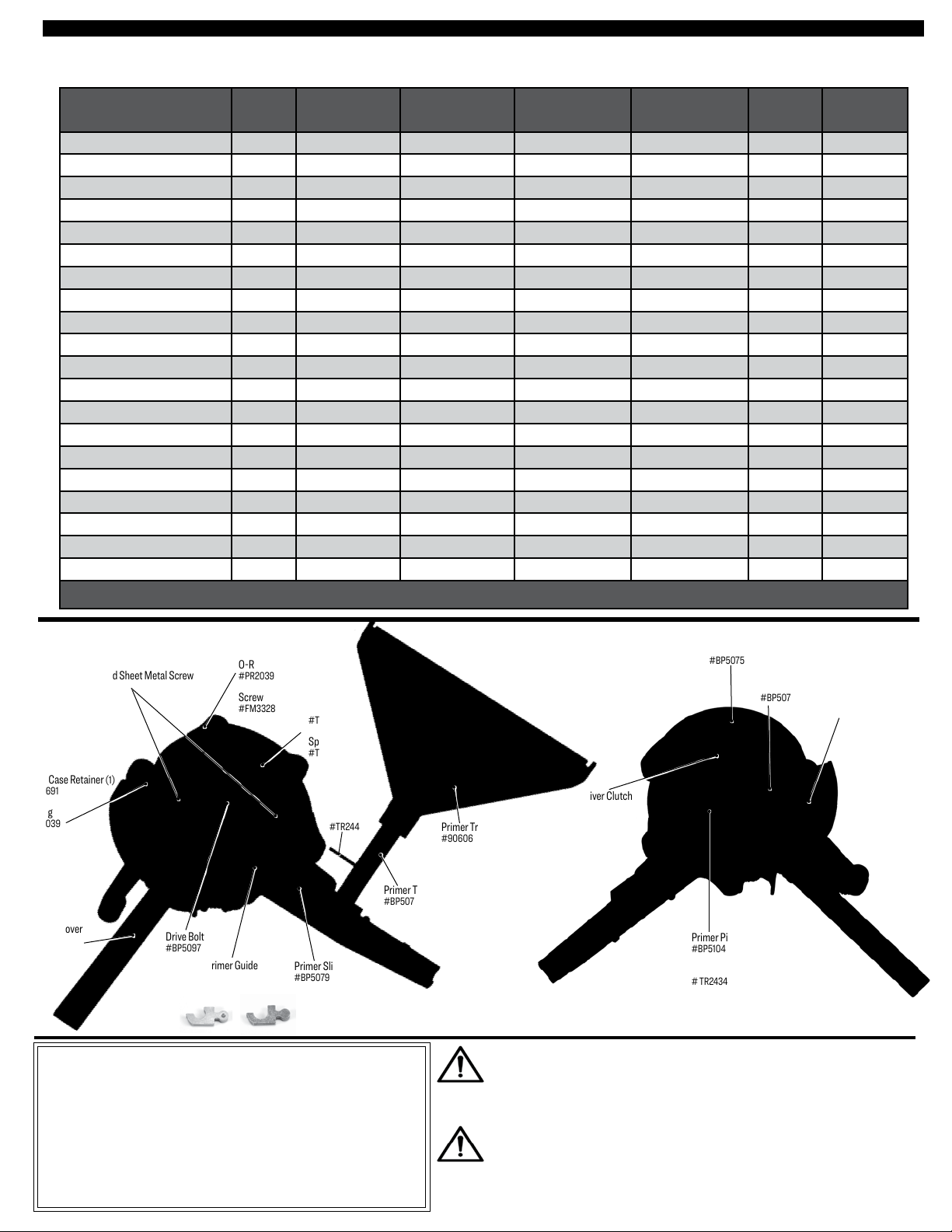

SHELL PLATE LISTINGSHELL PLATE LISTING ShellShell

PlatePlate Product Product

SPECIAL, MAG SPECIAL, MAG SS

ACP, CREED ACP, CREED LL

x WAT., SWISS x WAT., SWISS LL

ACP ACP SS

S&W LONG, H&R MAG. S&W LONG, H&R MAG. AA

BELTED MAGNUMS, MAG, BRITISH BELTED MAGNUMS, MAG, BRITISH

KRAG, MM WSMKRAG, MM WSM

LL

SS

M CARBINE, ACP M CARBINE, ACP SS

WIN, RIGBY WIN, RIGBY LL

MAGNUM MAGNUM LL

SWIFT, JAP, SOCOM SWIFT, JAP, SOCOM LL

MAG., SPL., COLT MAG., SPL., COLT LL

X MM PPC, PPCX MM PPC, PPC LL

COLT, S&W COLT, S&W LL

X FNX FN SS

S&W, XR S&W, XR LL

MM LUGER, S&W, SUPER, x TOKAREVMM LUGER, S&W, SUPER, x TOKAREV SS

MM AUTOMM AUTO LL

HORNET HORNET

REM SPC REM SPC LL