Electrical safety: double insulated

-2-

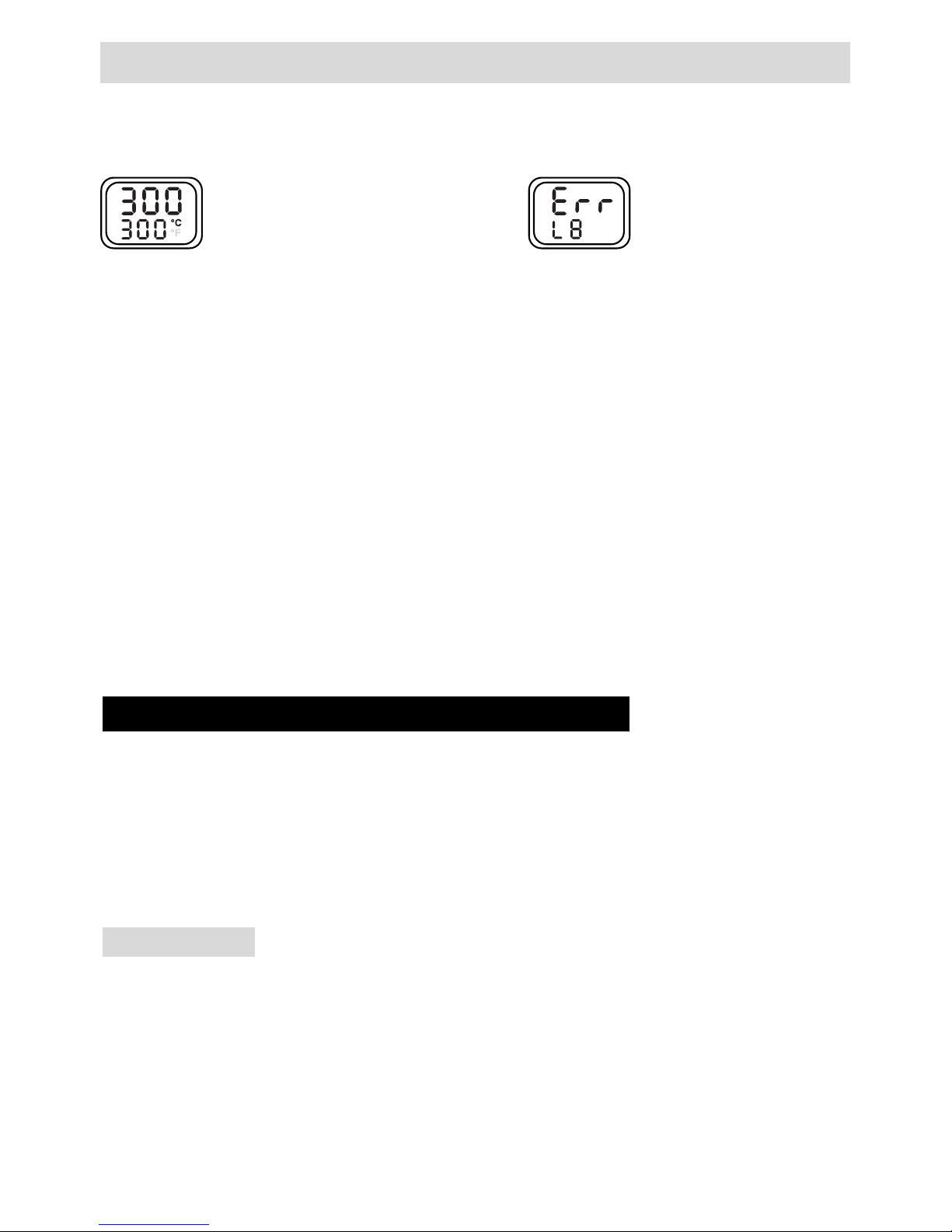

TEST SIGNS

TECHNICAL DATA

Voltage V~ 100 120 230

Frequency Hz 50/60 50/60 50/60

Capacity W 450 600 1000

Temperature °C 20 – 600 20 – 600 20 – 600

Air flow l/min. >40 >40 >40

Air pressure Pa max. 105 (dynamic)

Weight g 1000 with 3m cable, air hose and Y-connection

Size mm ø 32/43 × 270

Mains voltage cannot be switched over

This tool is CCA certificated (CENELEC Certification Agreement).

Danger to life when opening the tool, as live components

and connections ar exposed. Unplug the tool before

opening it.

Incorrect use of hot air blowers can cause fire and

explosion hazard, especially near combustible materials

and explosive gases.

The tool must be operated with supervision. Warmth can

reach combustible materials, which are out of sight.

For personal protection on building sites we strongly

recommend the tool be connected to a GFCI (Ground

Fault Circuit Interrupter) or a RCCB (Residual Current

Cir

cuit Breaker) .

The voltage rating stated on the tool must correspond to

the line/mains voltage.

Do not touch the element housing and nozzle when they

are hot as they can cause burns. Let the tool cool down.

Do not point hot air flow in the direction of people or

animals.

Protect tool from damp and wet.

FI

120

230

WARNING

CAUTION