-

c

-T!!!EZC

TABLE OF CONTENTS

PAGE

WARRANTY................................................................................................................................................

1

GENERAL INFORMATION ........................................................................................................................

2

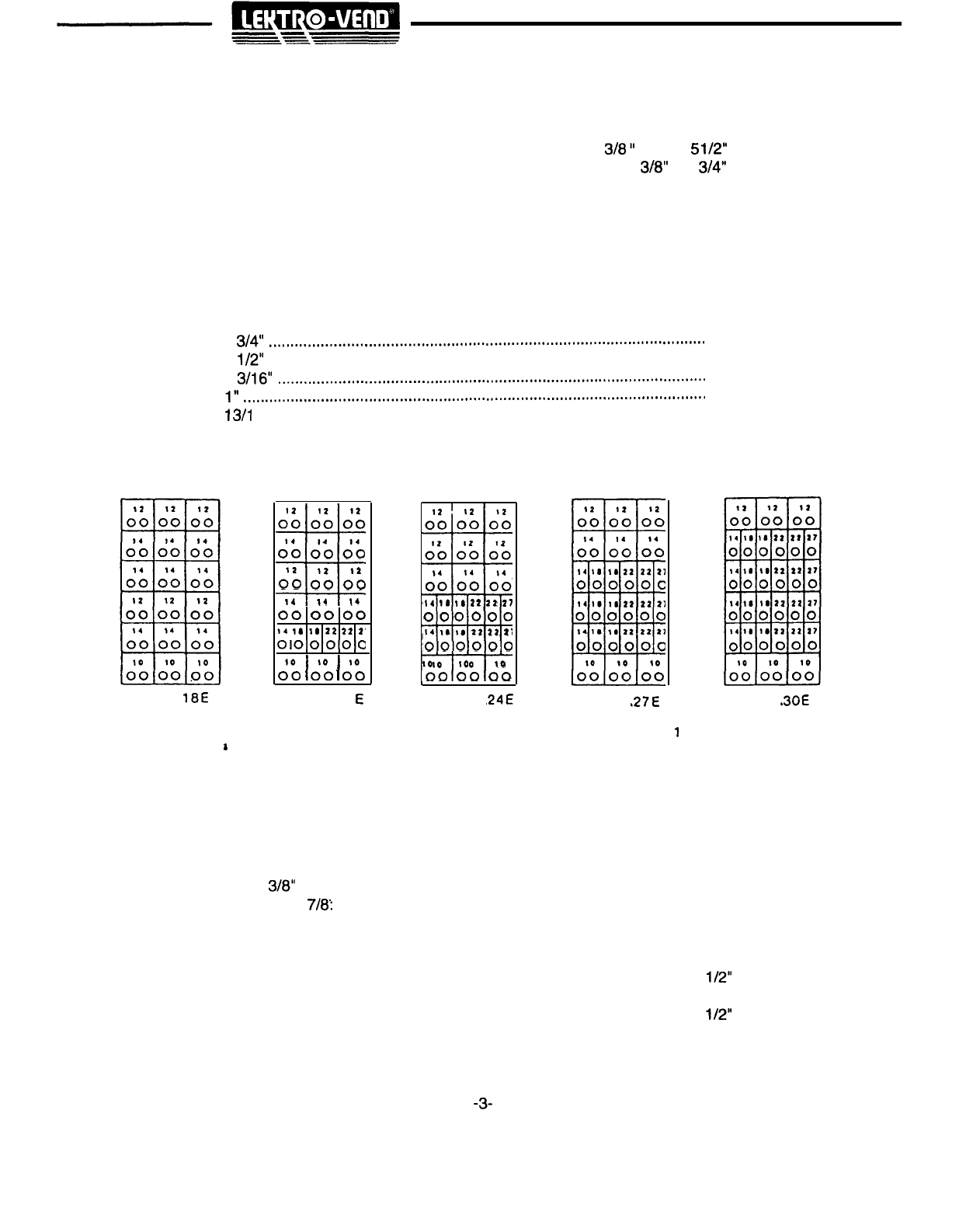

VENDING COMPARTMENT SPECIFICATIONS .......................................

.

...............................................

3

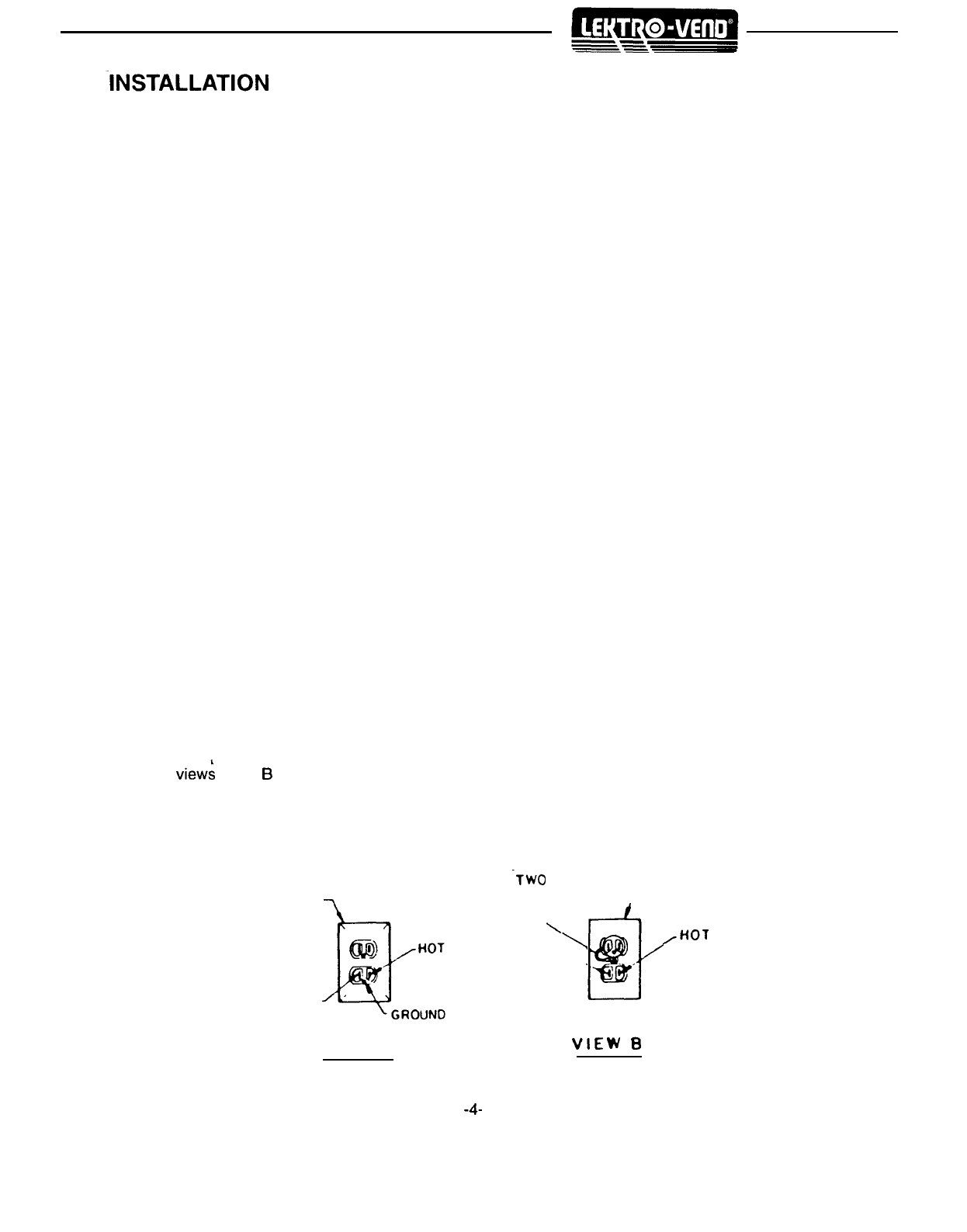

EQUIPMENT INSTALLATION.. ...............................................................................................................

4-5

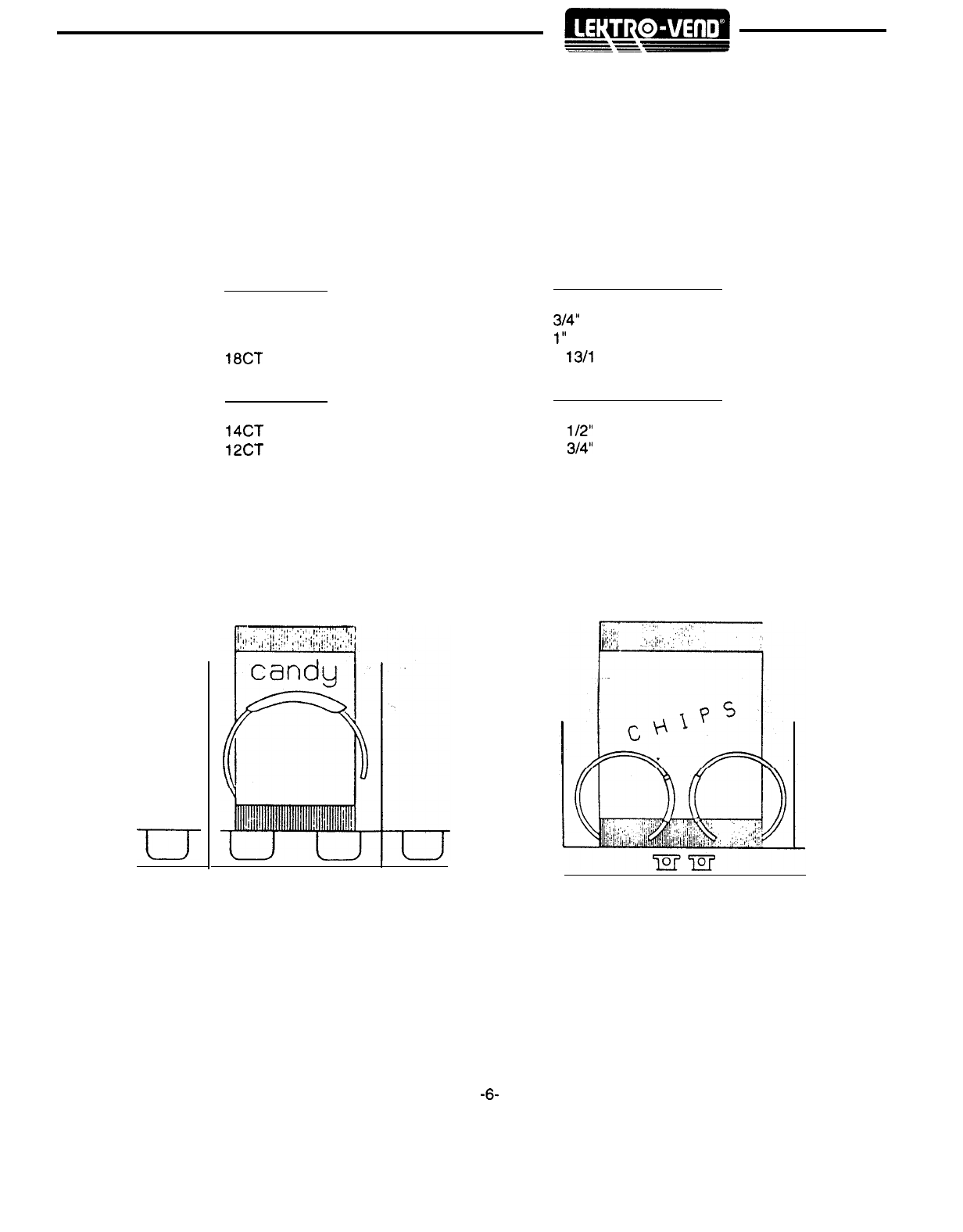

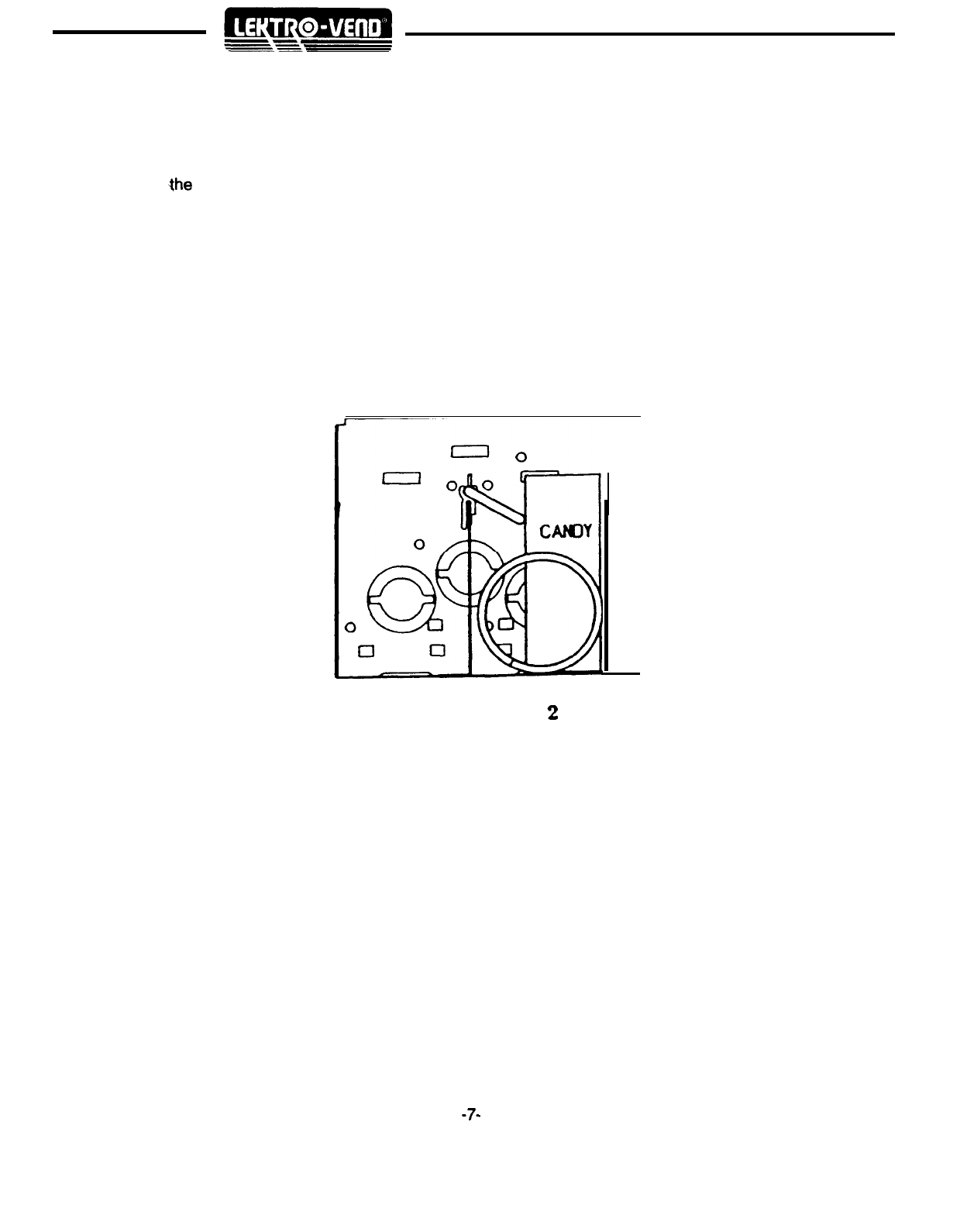

PRODUCT LOADING .............................................................................................................................

6-7

GUM

AND MINT LOADING .......................................................................................................................

8

CAROUSEL

LOADING

..............................................................................................................................

8

COLD FOOD

SIDE SET UP..

.......

i.............................................................................

.;.

.............................

9

REMOVING CAROUSEL JAM .................................................................................................................

10

CHANGING DIVIDER POSITIONS CAROUSEL TRAY...........................................................................

10

PRIMARY CABINET COMPONENT INFORMATION ..............................................................................

11

HEALTH SAFETY SWITCH OPERATION ...............................................................................................

12

SHOPPER SYSTEM OPERATION ..........................................................................................................

13

MACHINE THEORY

OF

OPERATION .....................................................................................................

14

ELECTRONIC SPECIFICATIONS ...........................................................................................................

15

ERROR

CODES........................................................................................................................................

15

ELECTRICAL SERVICE

SECTION

...............................................................................

i..

........................

16

DETAILED OPERATION

OF CONTROL

BOARD.. .............................................................................

17-25

COOLING SYSTEM INFORMATION .......................................................................................................

26

CLEANING AND MAINTENANCE ...........................................................................................................

SHIPPING POLICY .............................................................................................................................

28-z;

TROUBLE SHOOTING .......................................................................................................................

30-40

REFRIGERATION SYSTEM THEORY OF OPERATION ........................................................................

41

REFRIGERATION SYSTEM OPERATION ..............................................................................................

42

SOLENOID

COVER PANEL

REMOVAL ..................................................................................................

43

CHILLER ASSEMBLY REMOVAL AND INSTALLATION ........................................................................

43

PARTS

REPLACEMENT DIAGRAMS AND

PARTS LISTS

...................................................................

44

DOOR TRIM ASSEMBLY ...................................................................................................................

45-46

SHADOW

BOX

ASSEMBLY (SERVICE DOOR).................................................................................

47-48

DELIVERY DOOR (SERVICE DOOR) ................................................................................................

49-50

DOOR GLASS (SERVICE DOOR) ......................................................................................................

51-52

SERVICE DOOR ASSEMBLY (PRIMARY COMPONENTS) ..............................................................

53-54

COLD FOOD

AREA (PRIMARY COMPONENTS) ..............................................................................

55-56

LAMP

ASSEMBLY

(COLD FOOD

AREA) ...........................................................................................

57-58

TRAY SUPPORT ASSEMBLY ............................................................................................................

59-60

COLD FOOD DOOR ASSEMBLY .......................................................................................................

61-65

COLD FOOD DOOR

GASKET.. ...............................................................................................................

66

COIN

REJECT ASSEMBLY ................................................................................................................

67-68

POWER

SUPPLY ASSEMBLY ...........................................................................................................

69-70

POWER

SUPPLY WIRING HARNESS ....................................................................................................

71

POWER

SUPPLY SCHEMATIC.. .............................................................................................................

72

CHILLER ASSEMBLY .........................................................................................................................

73-76

CABINET ASSEMBLY (PRIMARY COMPONENTS) ..........................................................................

77-78

CAROUSEL COMPONENTS ..............................................................................................................

79-80

CAROUSEL ASSEMBLY .........................................................................................................................

81

CAROUSEL MOTOR ASSEMBLY ......................................................................................................

83-84

CABINET ASSEMBLY ........................................................................................................................

85-86

REAR CABINET ASSEMBLY ..............................................................................................................

87-88

ELECTRICAL SCHEMATIC

(WIRE

HARNESS

PART NOS.)

..................................................................

89