At this time, or shortly afterwards, the Heat Flash indicator bars on the Remote

handset will reduce from 3 bars to 2, and then 1 and finally no bars, as the heater

switches off.

When settled, the Heat Flash indicator will indicate the power being used in maintaining

the working temperature. Since proportional control is used, this will vary upon the oper-

ating environment.

8) The machine may now be operated fully as desired with due attention to all pre-

vailing safety regulations.

FLUID REPLACEMENT

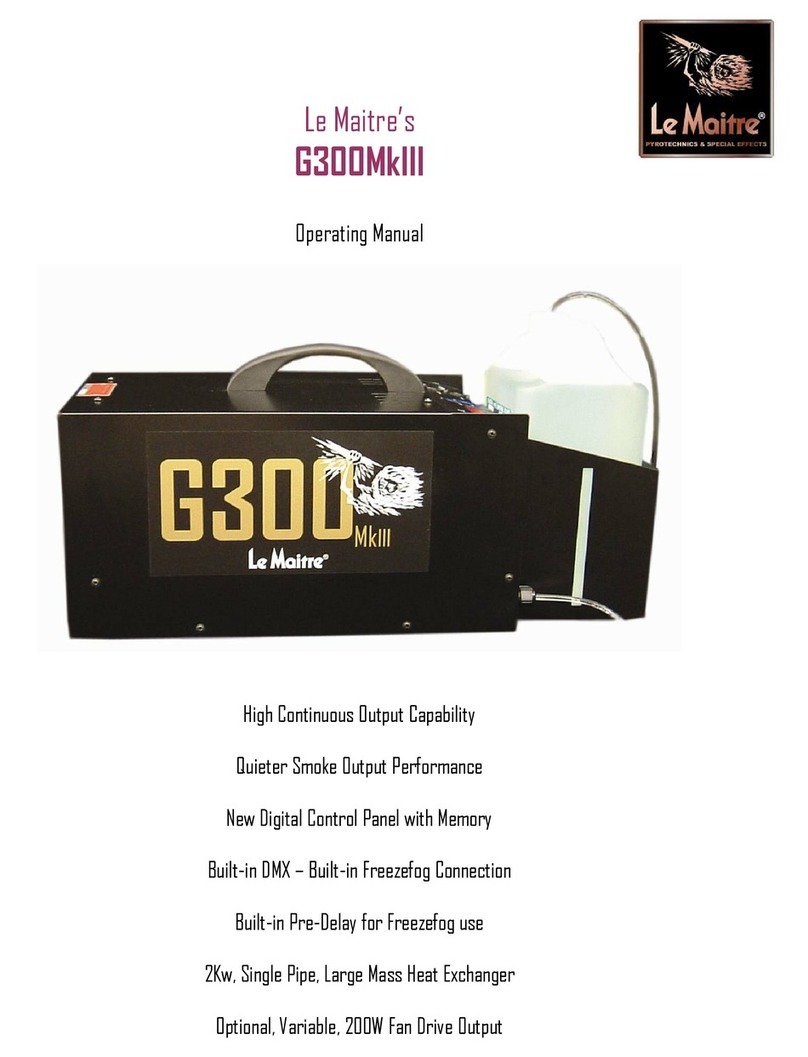

Replacing fluid does not require any attention to priming conditions. The G300 uses a

unique system of fluid pumping which allows fluid system replenishment without requir-

ing special settings of flow control.

HAZE FLOW CONTROL

The machine will change the characteristics of the Flow Rate settings when Haze mode

is in effect. This allows very short burst issues up to 5 seconds apart to be selected just by

the Flow Rate control when at its lowest on setting. ( 0 is actually no flow, which can

be useful if only a single channel 0 -10v control is available).

This decreases to every 4,3,2, and 1 seconds, after which point normal flow control com-

mences as the flow rate is increased.

This feature allows instant Hazing to be instigated by employing a high flow setting,

then allowing replenishment of loss by means of a low output, high velocity haze issue.

AUTOMATIC and CONTINUAL FLOW CONTROL

The G300 employs an extremely high accuracy thermal monitoring system. Combining this

with Micro-Processor control and a highly stable Patented Heat Exchanger, allows a self

management system to automatically adjust the flow rate for maximum conditions at any

temperature. This means that regardless of energy availability, a continual flow setting is

automatic. If the initial flow setting is high, then this will be decreased as flow continues,

until such time as a stable situation is attained.

Note:

Note:

Note:

6