2

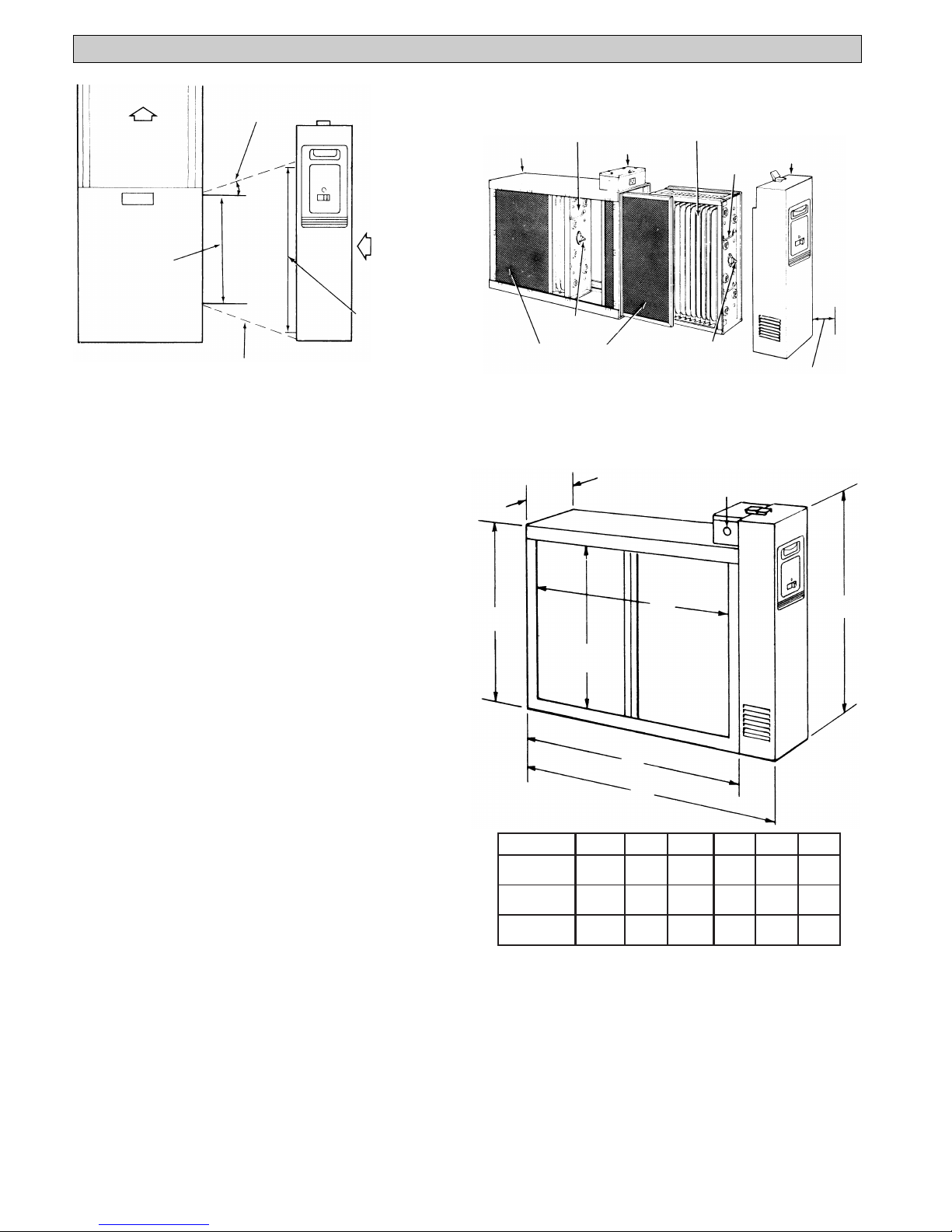

AB C

Unfiltered Air In Filtered Air Out

Before installing the air cleaner, make sure it is properly

sized for the application.

Model EAC-14 is designed for application with air han-

dlers which deliver air volumes up to 1600 cfm.

Model EAC-16 is designed for application with air han-

dlers which deliver air volumes up to 2000 cfm.

Model EAC-20 is designed for application with air han-

dlers which deliver air volumes up to 2200 cfm.

Refer to the specifications given on page 9.

Introduction .......................................................................... 1

Rules for Safe Installation and Operation .......................... 1

General Information ............................................................ 2

Parts Identification .............................................................. 3

Preinstallation ...................................................................... 4

Installation ........................................................................... 6

Wiring Instructions ............................................................... 7

Operation ............................................................................. 8

Maintenance ........................................................................ 8

Specifications ...................................................................... 9

Basic Service Guide .......................................................... 10

Service ............................................................................... 11

Healthy Climate®Electronic Air Cleaner Upgrade Kit ...... 13

Repair Parts ....................................................................... 14

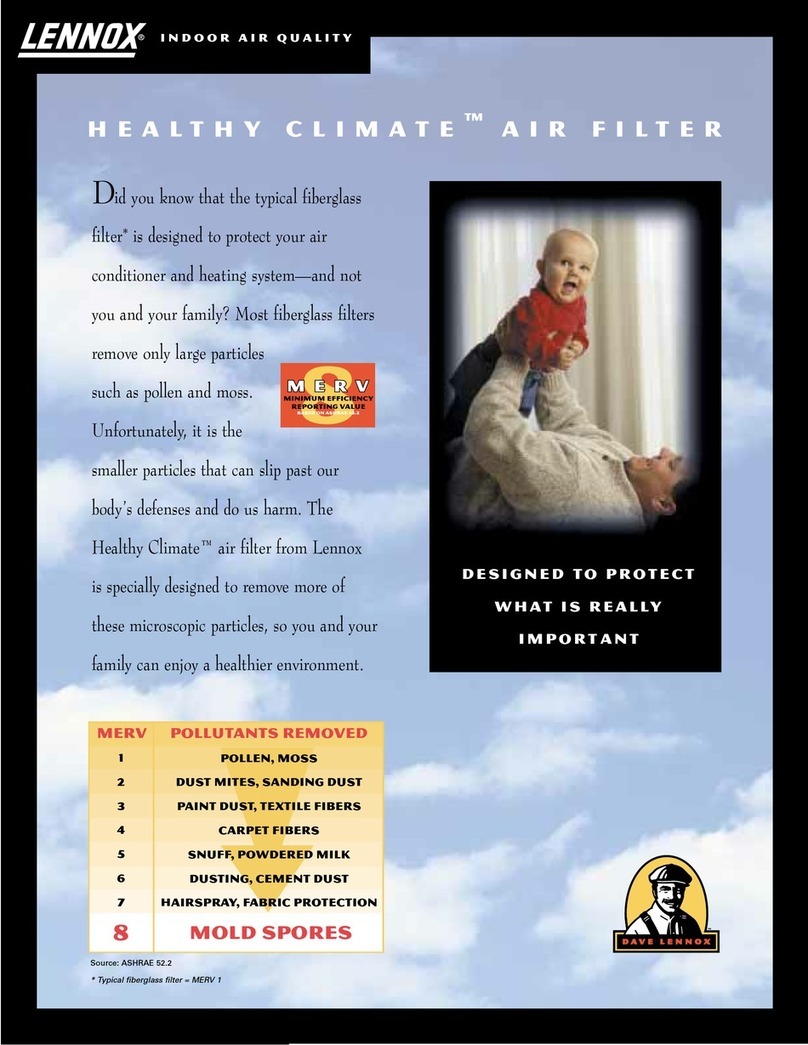

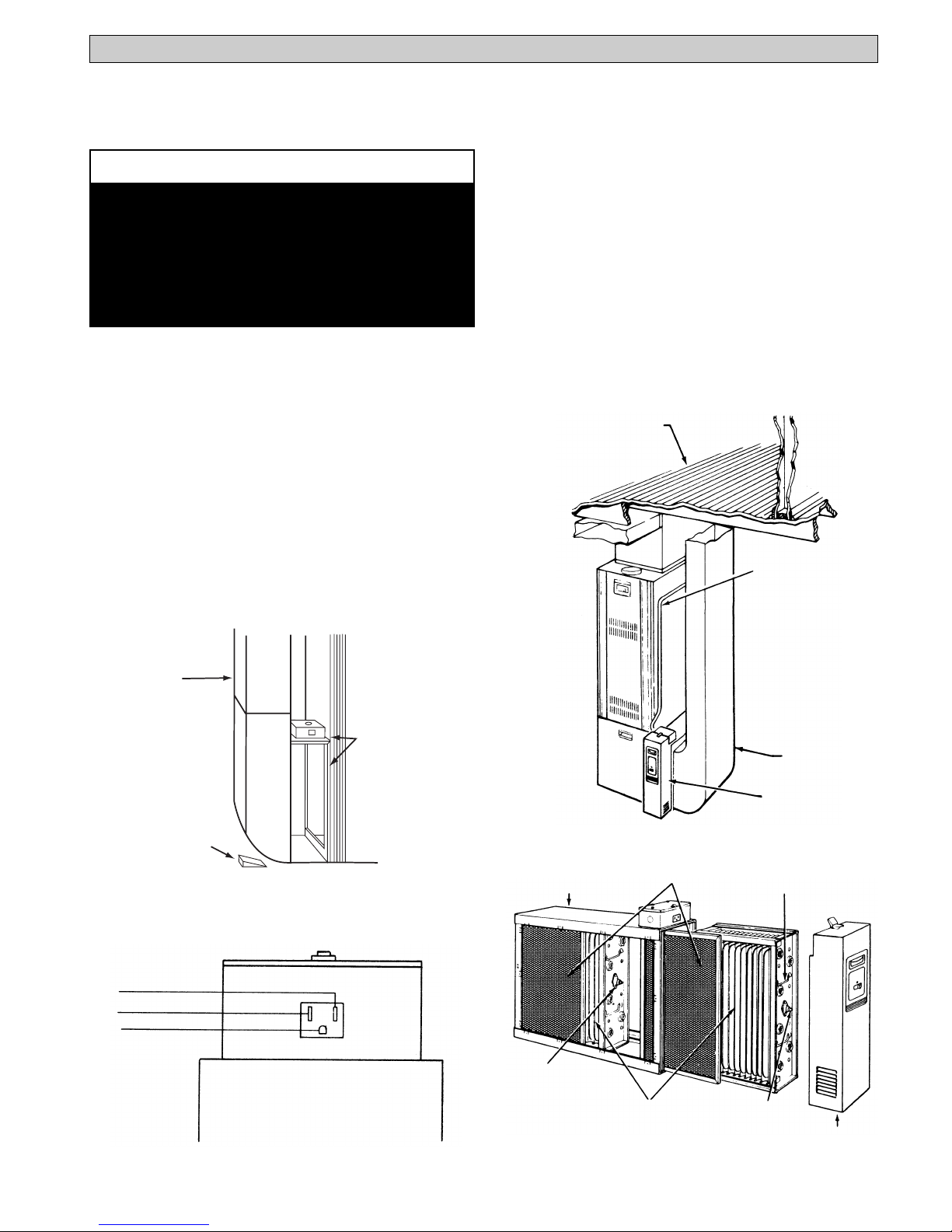

Air is drawn into the air cleaner from the return air duct. The

air enters the pre-filters (A) where large particles (hair, lint,

etc.) are trapped. The air continues into the ionizing section

(B), where the remaining smaller particles (smoke, dust,

pollen, etc.) are given a positive electrical charge. The

charged particles enter the collecting section (C), which is a

series of aluminum plates which are alternately charged

(negative and positive). See figure 1.

The positive charge of the particles causes them to be

repelled by the positive plates and attracted to the negative

plates where they are collected . . . just as a magnet

attracts iron filings.

The filtered air continues into the air handler where it is

conditioned and distributed throughout the supply air duct

system.

White Dust (Lint)

An electronic air cleaner is designed to collect two major

types of contaminants: ➀ irritants (pollens, spores, molds,

bacteria, etc.) and ➁black soiling contaminants (dirt and

smoke particles).

The residue on the collecting plates of an electronic air

cleaner is black, indicating it is removing dirt from the air

stream. After installing an air cleaner you may notice white

dust on darker colored, flat surfaces throughout your home.

This dust typically includes long linty particles or fibers from

carpets, cotton materials or drapery fabrics. This material is

not collected by the air cleaner because it does not contain

the irritants or soiling contaminants listed above or settles

out of the air before reaching the air cleaner. The presence

of white dust does not indicate an air cleaner requires

service.

Carbon (Charcoal) Filters

Odors are gas molecules, not particles. For best odor

removal options, ask your Lennox dealer about other

Healthy Climate products, such as the PureAirTM air

purification system. However, some gases can be absorbed

by an activated carbon filter or diluted with fresh outdoor

air. When odors are present, the addition of charcoal filters

will neutralize many odors, such as cooking odors, pet

odors, cigar and cigarette odors, ozone, etc. Optional

charcoal filters are available for your Air Cleaner. Refer to

the parts list for the charcoal filter part number for your Air

Cleaner. Charcoal filters must be replaced every six

months, or more frequently if necessary. They cannot be

washed. While there is no rule of thumb for how often they

should be changed, you can use your best judgement

based on the odors you perceive in your environment.

Figure 1

Table of Contents Air Cleaner Sizing

General Information