2

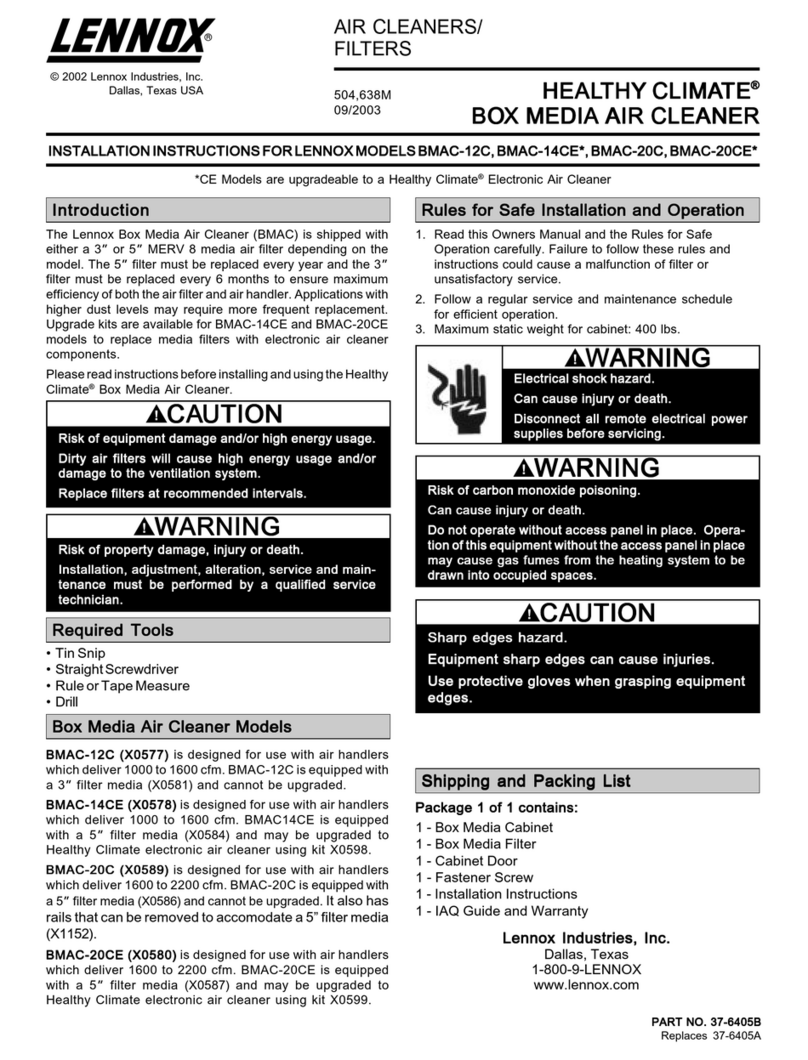

Shipping and Packing List

Assembled PureAir S air purication system which includes:

• Cabinet (1)

• UVA Lampholder / PCO cartridge (secure to interior

of cabinet) (1)

• UVA lamp in box (secure to interior of cabinet) (1)

• Healthy Climate® Carbon Clean 16®Filter (located in

interior of cabinet) (1)

• UVA lamp socket with 4-pin male connector assembly

attached to light ballast electrical connector (1)

• Lennox Communication Control interface.

• Literature bag includes power cord (120VAC)1, instal-

lation instruction, UVA Lamp Socket brass nger nuts

(2), UVA Lampholder / PCO cartridge wing nuts (2)

and warranty.

1230VAC power cord available separately (part number

91X44).

Check equipment for shipping damage. If damage is found,

immediately contact last carrier.

Models

Table 1. Unit Catalog Numbers

Model Catalog Number

PCO3S-14-16 Y8905

PCO3S-16-16 Y8904

PCO3S-20-16 Y8903

Application

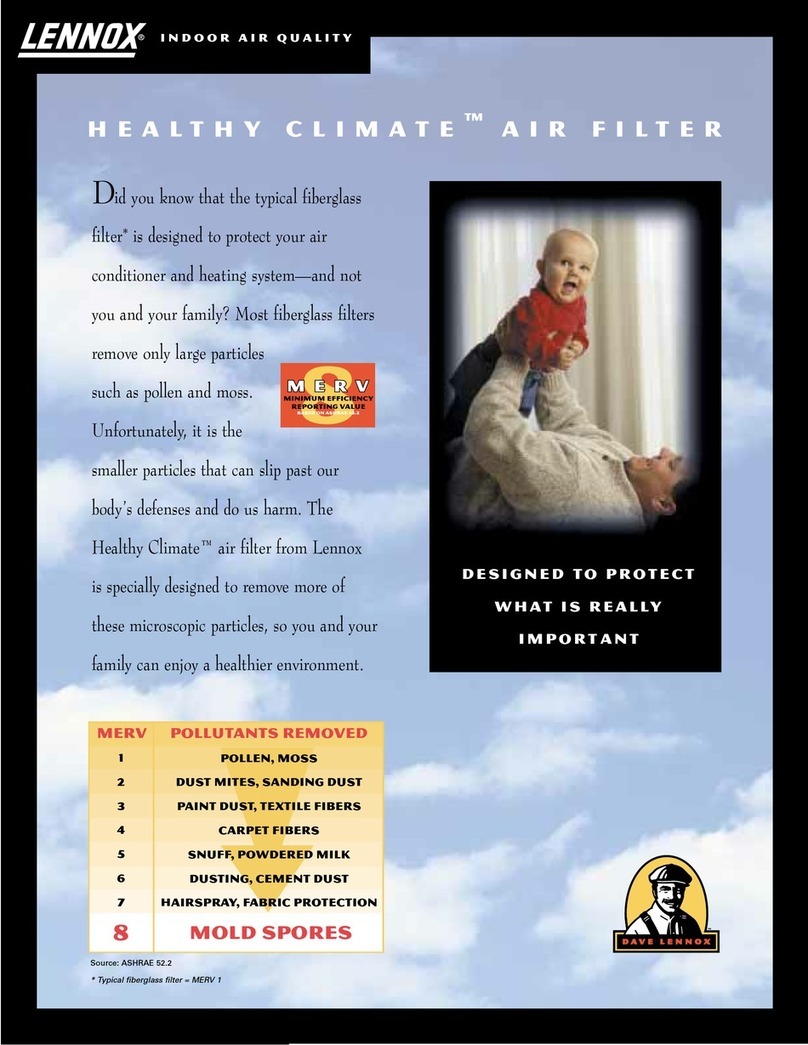

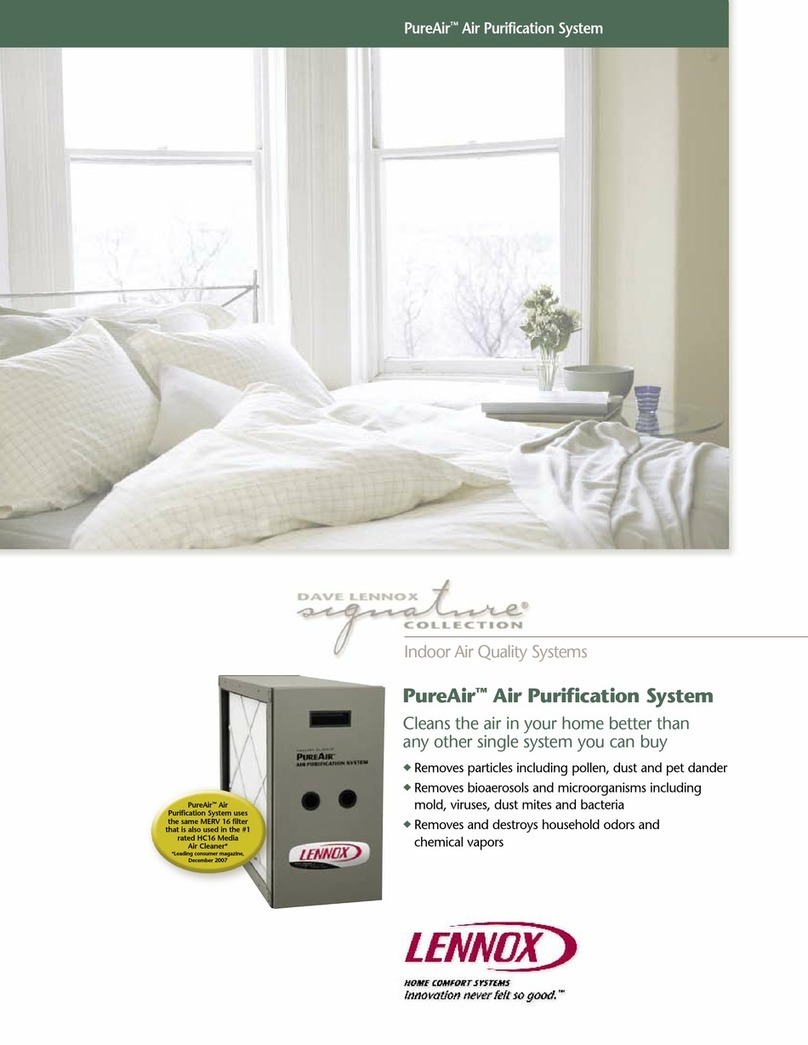

The PureAir S air purication system uses photocatalytic

oxidation (PCO) technology to reduce levels of airborne

volatile organic compounds, cooking odors, common

household odors, airborne dust particles, mold spores and

pollen. Each unit may be connected to either 120VAC or

230VAC power supply.

Lab tests conrm a 50% reduction in total volatile organic

compounds (TVOC) within the rst 24 hours of initial

operation of the PureAir S air purication system. It may

take up to 48 hours after initial system start-up to reduce

the airborne chemicals that have built up in a home over a

long period of time.

For peak performance, unit should be installed in homes

with TVOC levels that are less than 1000 micro-gram /

cubic meter. Home source removal and ventilation may be

required to lower total volatile organic compounds to this

level.

The Healthy Climate® Carbon Clean 16®Filter combines

industry-leading MERV 16 ltration and carbon-coated ber

matrix.

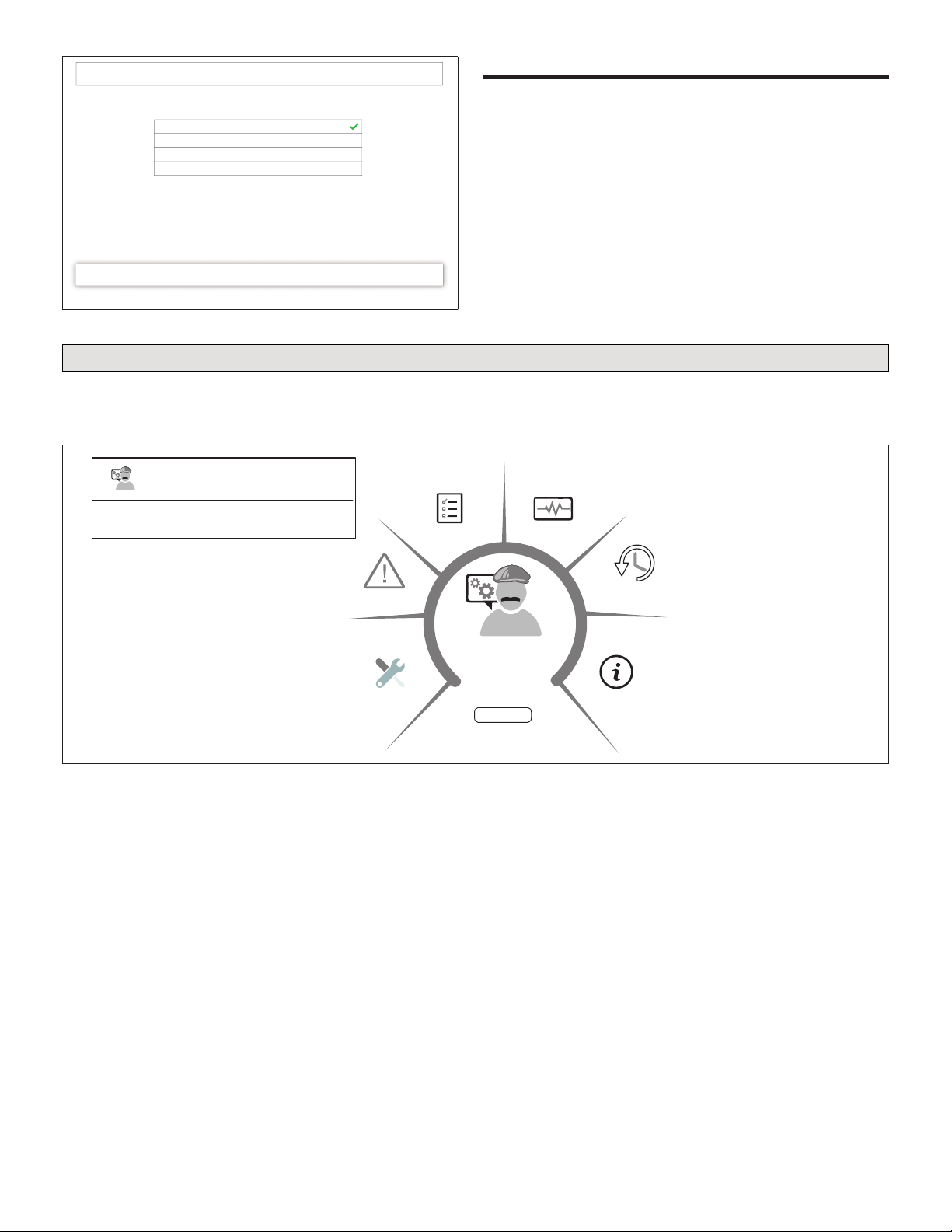

For full feature benets, the PureAir Smust be used with

an S30 Ultra Smart Thermostat and communicating indoor

unit.

The iComfort S30 Ultra Smart Thermostat will require

rmware version 3.4 or higher to take advantage of all of

the PureAir Sfeatures.

New features included are:

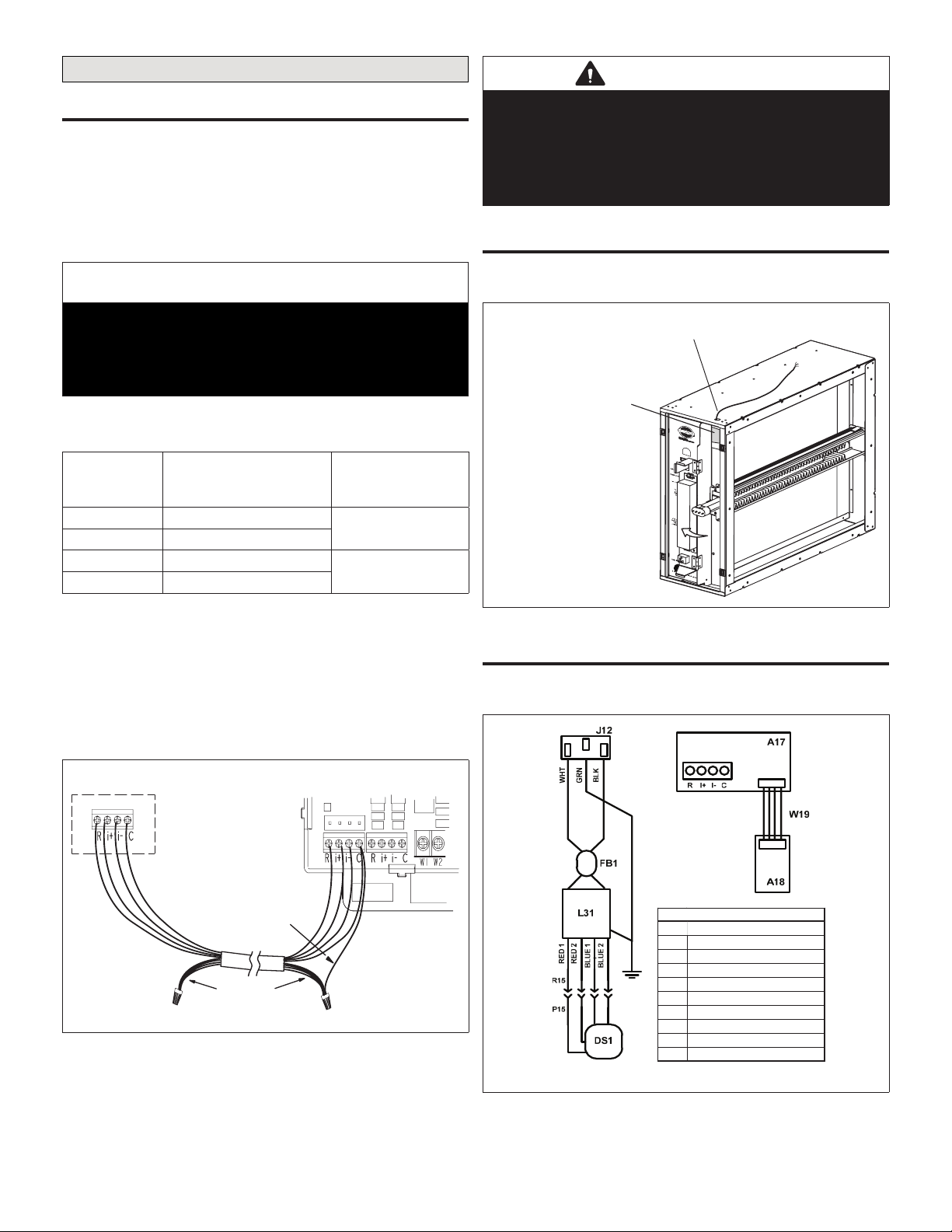

• 4-wire connection to Lennox communicating indoor

unit control

• Using sensors to:

> Automatically detect dirty air lter

> Display air lter life percentage

> Monitor UVA lamp operational state (On or Off).

> Display UVA lamp life percentage

IMPORTANT

Oil on metal ducts may cause odors.

Use a mild soap and water solution to remove oils from

transitions and duct surfaces prior to installation.

IMPORTANT

Do not use any form of silicone sealant.

Use of silicone-based products will reduce the

effectiveness of, or damage the titanium dioxide coatings

on the PCO cartridge.

IMPORTANT

Route power cord away from trafc areas where the cord

may become a safety hazard.

IMPORTANT

UVA lamp life is shortened when lamp is turned off and on.

Power to unit must remain on at all times.

Do not interlock lamp operation with air handler blower

operation.

CAUTION

Ultraviolet (UVA) radiation risk.

Prolonged exposure may cause skin or eye damage.

Avoid prolonged (weeks) exposure to skin or eyes.

WARNING

Risk of carbon monoxide poisoning.

Can cause injury or death.

Do not operate system unless access panel is in place

and properly secured. Operation of this equipment without

the access panel in place may cause exhaust fumes to be

drawn into occupied spaces.

CAUTION

Sharp edges hazard.

Sharp edges can cause injuries.

Use protective gloves when grasping equipment edges.