ML14XC1 - 1.5 to 5 Ton Air Conditioner / Page 2

WARRANTY

Compressor - limited warranty for ve years in

residential installations and ve years in non-residential

installations.

All other covered components - ve years in

residential installations and one year in non-residential

installations.

Note - Refer to Lennox Equipment Limited Warranty

certicate included with unit for specic details.

APPROVALS

AHRI Certied to AHRI Standard 210/240-2008.

Sound rated in Lennox reverberant sound test room

in Accordance with test conditions included in AHRI

Standard 270-2008.

Tested in the Lennox Research Laboratory

environmental test room.

Rated According to U.S. Department of Energy (DOE)

test procedures.

Region specic models meet the minimum efciency

requirements for U.S DOE Federal Regional Standards

in that area.

Units and components within bonded for grounding to

meet safety standards for servicing required by UL,

NEC and CEC.

Units are ETL certied for the U.S. and Canada.

ISO 9001 Registered Manufacturing Quality System.

For expanded ratings, see www.LennoxPROs.com.

APPLICATIONS

SEER up to 17.00.

1.5 through 5 ton.

Single-phase power supply.

Sound levels as low as 73 dB.

Vertical air discharge allows concealment behind shrubs

at grade level or out of sight on a roof.

Matching add-on furnace indoor coils or air handlers

provide a wide range of cooling capacities and

applications. See AHRI System Matches.

See Indoor Coils and Air Handlers sections for data.

Units shipped completely factory assembled, piped and

wired. Each unit test operated at the factory ensuring

proper operation.

Installer must set air conditioner, connect refrigerant

lines and make electrical connections to complete job.

REFRIGERATION SYSTEM

R-410A Refrigerant

Non-chlorine, ozone friendly, R-410A.

Unit pre-charged with refrigerant.

See Specication table.

Outdoor Coil Fan

Direct drive fan moves large air volumes uniformly

through entire condenser coil for high refrigerant cooling

capacity.

Vertical air discharge minimizes operating sounds and

eliminates damage to lawn and shrubs.

Fan motor has sleeve bearings (-018 through -048

and -060 models), ball bearings (-059 model) and is

inherently protected.

Motor totally enclosed for maximum protection from

weather, dust and corrosion.

Rain shield on motor provides additional protection from

moisture.

Louvered steel top fan guard furnished as standard.

Fan service access accomplished by removal of top

panel.

High Pressure Switch

Shuts off unit if abnormal operating conditions cause the

discharge pressure to rise above setting.

Protects compressor from excessive condensing

pressure.

Manual reset.

Lennox Quantum™ Coil

Enhanced aluminum alloy tube/enhanced n coil for

superior corrosion resistance.

Lennox designed and fabricated coil.

Ripple-edged aluminum ns.

Aluminum tube construction.

Lanced ns provide maximum exposure of n surface to

air stream resulting in excellent heat transfer.

Fin collars grip tubing for maximum contact area.

Flared shoulder tubing connections/silver soldering

construction.

Coil is factory tested under high pressure to ensure

leakproof construction.

Steel louvered panels provide complete coil protection.

Panels can be completely removed for servicing.

A

B

C

B

C

D

E

F

FEATURES

CONTENTS

AHRI System Matches - All Regions ......................... 11

AHRI System Matches - North / South Regions........ 36

AHRI System Matches - Southwest Regions ............ 78

Dimensions - Unit ........................................................ 8

Electrical Data.............................................................. 6

Features....................................................................... 2

Field Wiring.................................................................. 5

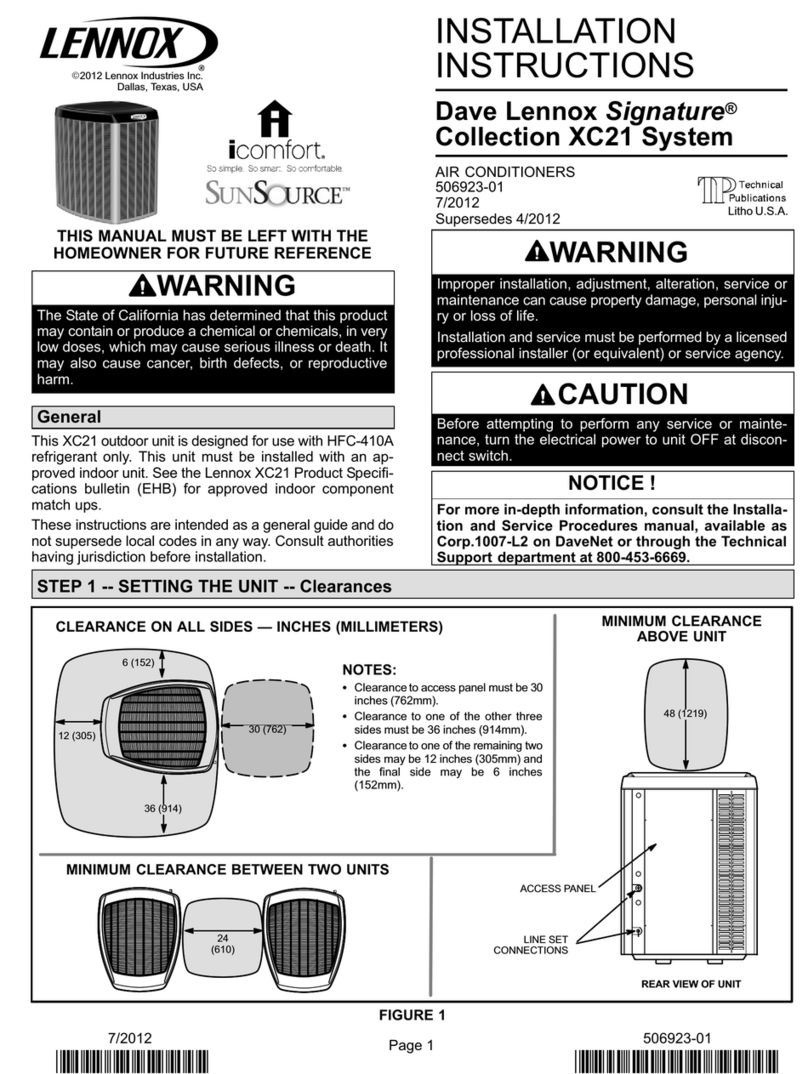

Installation Clearances ................................................ 5

Model Number Identication........................................ 1

Optional Accessories ................................................... 6

Sound Data.................................................................. 9

Specications............................................................... 6