NOTE -See outdoor unit instructions on how to flow

nitrogen through line sets.

Step 1_ Remove access panel,

Step 2,, Remove the refrigerant line caps from the

refrigerant lines,

Step 3,, Use a wet rag to protect TXV sensing bulb (or

remove it) when brazing suction line

connections,

Step 4..

Step 5..

Step 6_

Step 7_

Step 8..

Place a wet rag against piping plate and around

the suction line connection, The wet rag must be

in place to guard against damage to the paint,

With the wet rag in place, position a field

provided elbow fitting to the air handler's suction

line and line set, Start nitrogen flow before

brazing,

After the procedure is completed then remove

the wet rag,

Place wet rag against piping plate and around

the liquid line connection. Position liquid line

elbow to air handler's suction line and to line set.

Start nitrogen flow and begin brazing both

connections and after procedure is completed

then remove both wet rags,

Refer to instructions provided with outdoor unit

for leak testing, evacuating and charging

procedures,

Step 9_ Install access panel,

Table 2. Refrigerant Line Sets

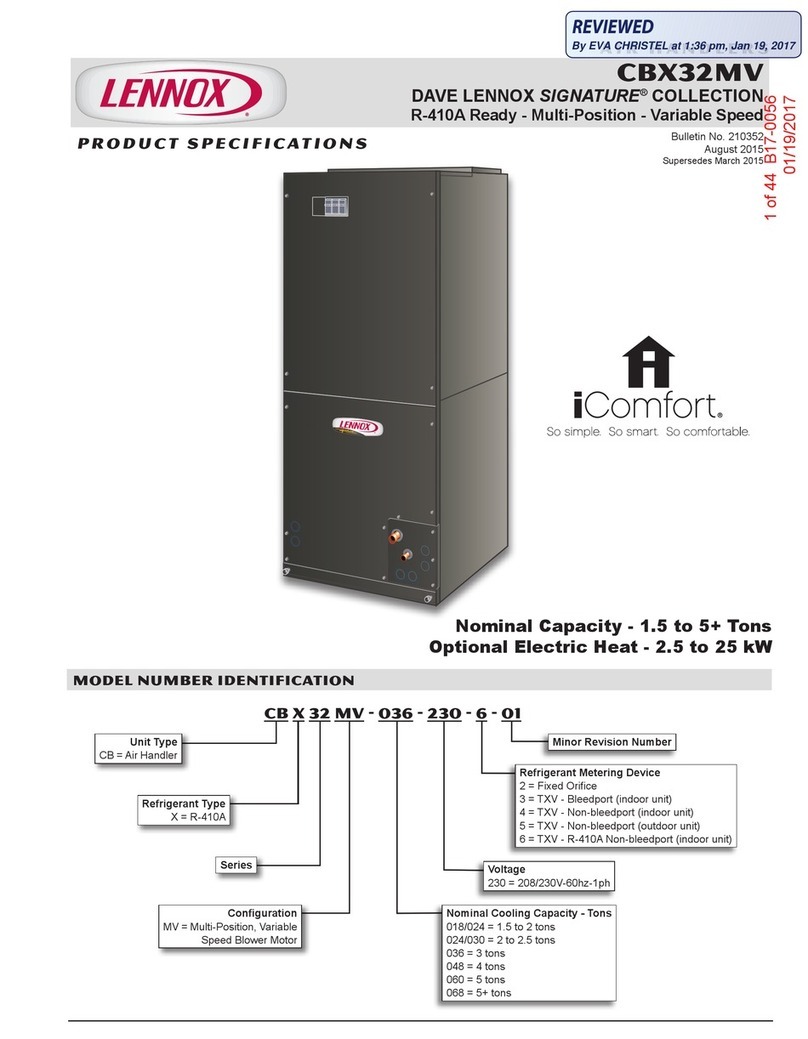

CBX32M Liquid Vapor/ L10 L15

Units Line No. Suction Line Line Sets Line Sets

-018/024 3/8 in 5/8 in L10-26 L15-26

(Smm) (16 mm) 20 ft. - 50 ft. 20 ft. -50 fb

(6 m- 15 m) (6 m- 15 m)

-030,-036 3/8 in 3/4 in. L10-41 L15-41

(10 mm) (19mm 20 ft. - 50 ft. 20 ft. -50 ft.

(6m-15m) (6m-15m)

-042, -048 3/8 in 7/8 in. L10-65 L15-65

(10 mm) (22 mm) 30 ft. - 50 ft. 30 ft. -50 ft.

(9 m- 15 m) (9 m- 15 m)

-060 3/8 in 1-1/8 in. Field Field

(10 ram) (29 ram) Fabricated Fabricated

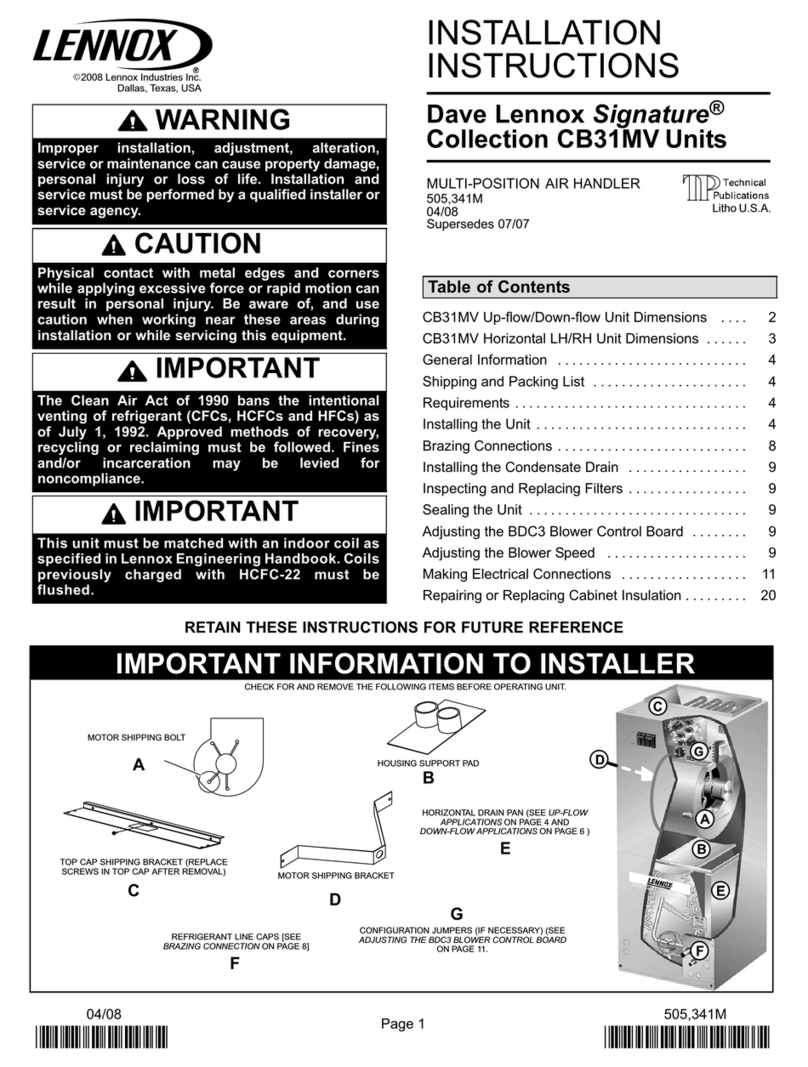

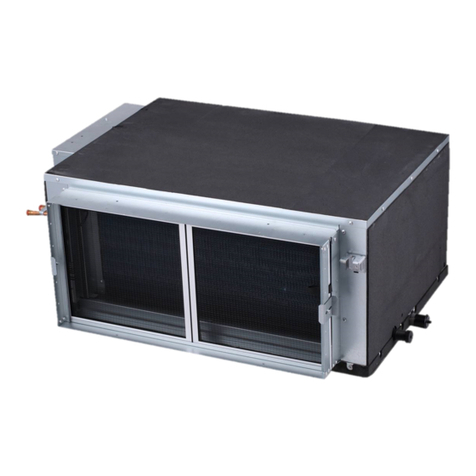

Before connecting drain line(s), check drain hole(s) to

verify that drain opening is fully open and free of any

debris. Also check to make sure that no debris has fallen

into the drain pan during installation that may plug up the

drain opening,

Connect main condensate drain and route downward to an

open drain or sump. Do not connect drain to a closed waste

system. Refer to figure 9 on page 8 for typical condensate

trap configuration.

It is recommended that the auxiliary drain be connected to

a drain line for all units. Ifauxiliary drain is not connected, it

must be plugged with provided cap. For down-flow units,

the auxiliary drain shall be connected and routed to a drain.

See figure 10 for auxiliary and main drain locations,

The following practices are recommended to ensure

condensate removal as illustrated in figures 9 and 10:

• Drain piping should not be smaller than the drain

connections at drain pan.

• A trap must be installed in the main drain line,

• The trap must be deep enough to offset the difference

in static pressure between drain pan and atmosphere.

Generally, two inches is satisfactory for medium static

applications.

• Horizontal runs must be sloped 1 inch per 10 feet of

drain line to offset friction,

• An open vent in drain line will sometimes be required due

to line length, friction and static pressure,

• Drain construction and routing should facilitate future

cleaning and must not interfere with filter access,

• Auxiliary drain should run to an area where

homeowner will notice any drainage. The auxiliary

drain line does not required venting or a trap. Refer to

local codes.

VENT MUST EXTEND ABOVE THE HEIGHT OF THE COIL"

DRAIN PAN BY 2 INCHES (51 MM). VENT

DRAIN PAN

TRAP MUST BE DEEP ENOUGH TO OFFSET

MAXIMUM STATIC DIFFERENCE (GENERAL

2 INCHES [51MM]).

TRAP (49P66)

DRAIN LINE SHOULD SLOPE A MINIMUM 1 INCH PER

10 FEET (25 MM PER 3 M) TO APPROVED DRAIN

Figure 9. Typical Condensate Drain Connection

LEF%HAND UP-FLOW OR RIGHT-HAND

DISCHARGE DOWN-FLOW DISCHARGE

w

AUXILIARY DRAIN ON LEFT

oo ]

MAIN DRAIN ON RIGHT

Figure 10. Drain Locations

505342M 05/08

Page 8