Page 9

CAUTION

When using drynitrogen,apressurereducing reg-

ulatormustbeusedto preventexcessive pres-

surein gaugemanifold,connecting hoses,and

withinthe system.Regulatorsetting mustnotex-

ceed150 psig(1034 kpa).Failureto use a regulator

cancause equipment failureresulting ininjury.

C-Evacuating theSystem

1-Attachgaugemanifold.Connectvacuumpump(withvac-

uumgauge)tocenterportofgauge manifold.With both

manifoldservicevalvesopen,startpump and evacuate

indoorcoil and refrigerantlines.

IMPORTANT

Atemperature vacuumgauge,mercury vacuum

(U-tube),orthermocouplegauge should beused.

TheusualBourdon tubegauges arenotaccurate

enough inthe vacuumrange.

IMPORTANT

The compressorshould neverbeusedtoevacu-

atearefrigeration orairconditioning system.

2-Evacuatethe systemto 29 inches(737mm)vacuum.

During the early stagesofevacuation,itisdesirableto

stopthevacuumpumpatleastoncetodetermineifthere

isarapidloss ofvacuum.Arapidloss ofvacuumwould

indicatealeakinthe systemand a repeatof the leak

testing section would be necessary.

3-Aftersystemhasbeen evacuated to 29 inches

(737mm),close gauge manifoldvalvestocenterport,

stop vacuumpump and disconnect fromgauge man-

ifold.Attach an uprightnitrogen drumtocenterportof

gaugemanifold andopendrumvalveslightlytopurge

line atmanifold.Break vacuuminsystemwith nitro-

gen pressure byopening manifold high pressure

valve.Closemanifold high pressurevalvetocenter

port.

4-Close nitrogen drumvalve and disconnect from

gaugemanifoldcenterport.Releasenitrogenpres-

surefromsystem.

5-Connectvacuumpumpto gauge manifoldcenter

port. Evacuatesystemthrough manifoldservice

valvesuntil vacuuminsystemdoesnotrise above

.5mm ofmercuryabsolute pressure or500 microns

within a 20-minute period afterstopping vacuumpump.

6-Afterevacuation is complete,closemanifoldcenterport,

and connectrefrigerantdrum.Pressurizesystem

slightlywithrefrigerant to break vacuum.

D-Charging

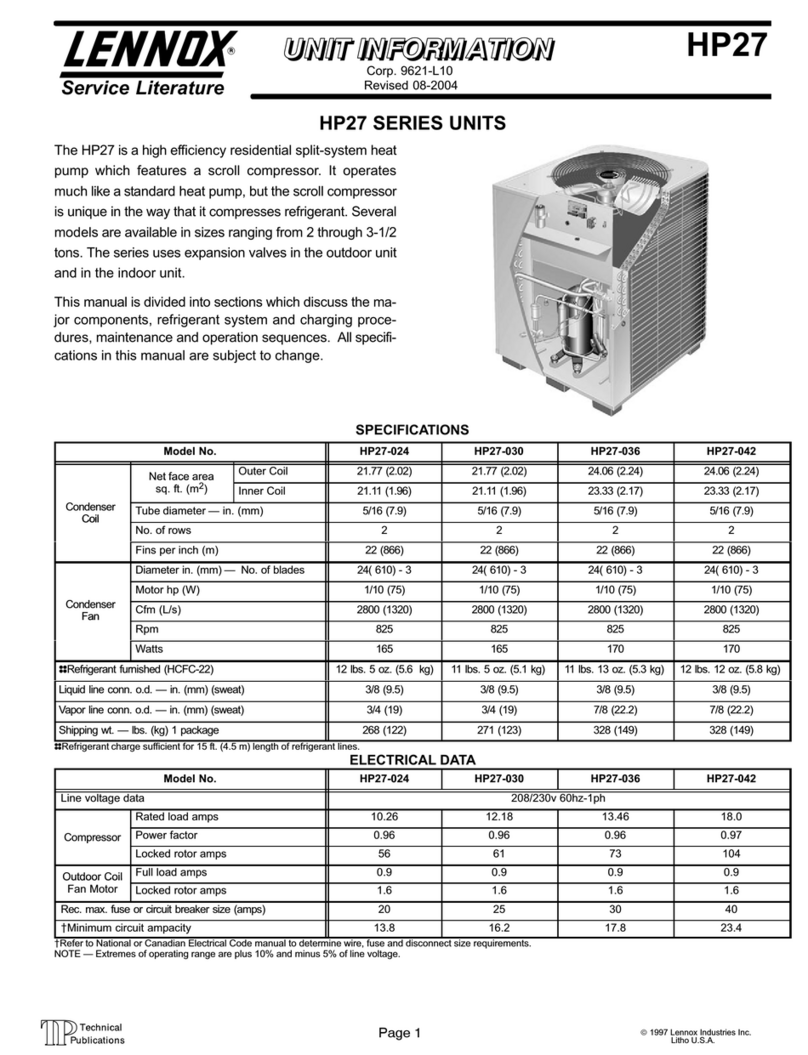

Unitsarefactory charged withthe amountofHCFC-22 re-

frigerantindicated on the unitnameplate.This charge is

basedonamatching indoorcoil and outdoorcoil with a 20

ft. (6.1m)line set. Forvarying lengthsofline set, referto

table 2 for refrigerantcharge adjustment. Ablank spaceis

provided on the nameplatetolist the actualfieldcharge.

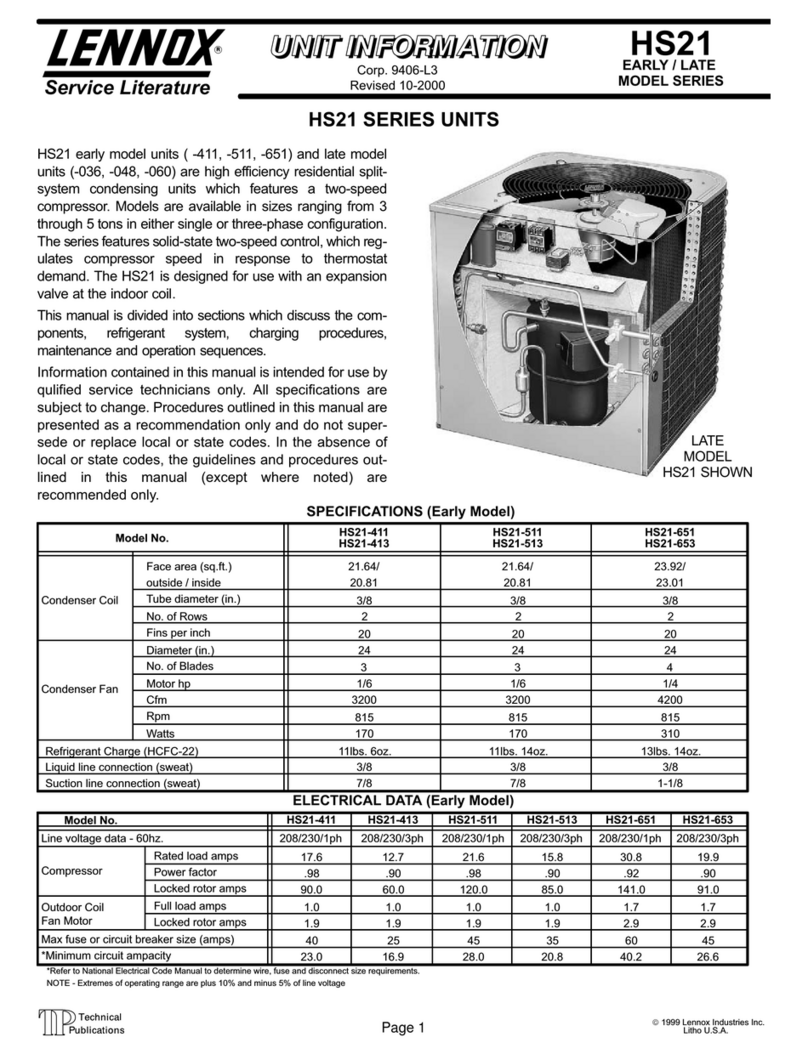

TABLE2

Liquid Line

SetDiameter

Oz.per5ft.(g per1.5m)adjust

from20 ft.(6.1m)line set*

5/16 in.(8mm)2 ounce per5ft. (57g per1.5m)

3/8in.(10 mm)3 ounce per5ft. (85g per1.5m)

*If line lengthisgreaterthan 20 ft. (6.1m),add thisamount.

If line lengthisless than 20 ft. (6.1m),subtract thisamount.

The condensing unitshouldbecharged during warm

weather.However,applicationsariseinwhichcharging

mustoccurinthecoldermonths.The method ofcharging is

determined bythe unit’srefrigerantmetering device and

the outdoorambient temperature.

Measurethe liquidline temperature and the outdoorambi-

ent temperature asoutlined below:

1.-Connect the manifold gauge set tothe servicevalves:

lowpressure gauge tosuction valveservice port; high

pressure gauge toliquidvalveservice port. Connect

the centermanifold hoseto an uprightcylinderof

HCFC-22.Closemanifold gauge setvalves.

2.-Settheroomthermostattocallforheat.Thiswillcreate

thenecessaryloadforproperlychargingthe systemin

the cooling cycle.

3.-Useadigitalthermometertorecordthe outdoorambi-

ent temperature.

4.-When the heating demand hasbeen satisfied,switch

thethermostat tocoolingmodewithasetpointof68_F

(20_C).When pressureshavestabilized,use a digital

thermometertorecordthe liquidline temperature.

5.-The outdoortemperaturewill determine whichcharg-

ing method to use.Proceed withthe appropriate

charging procedure.