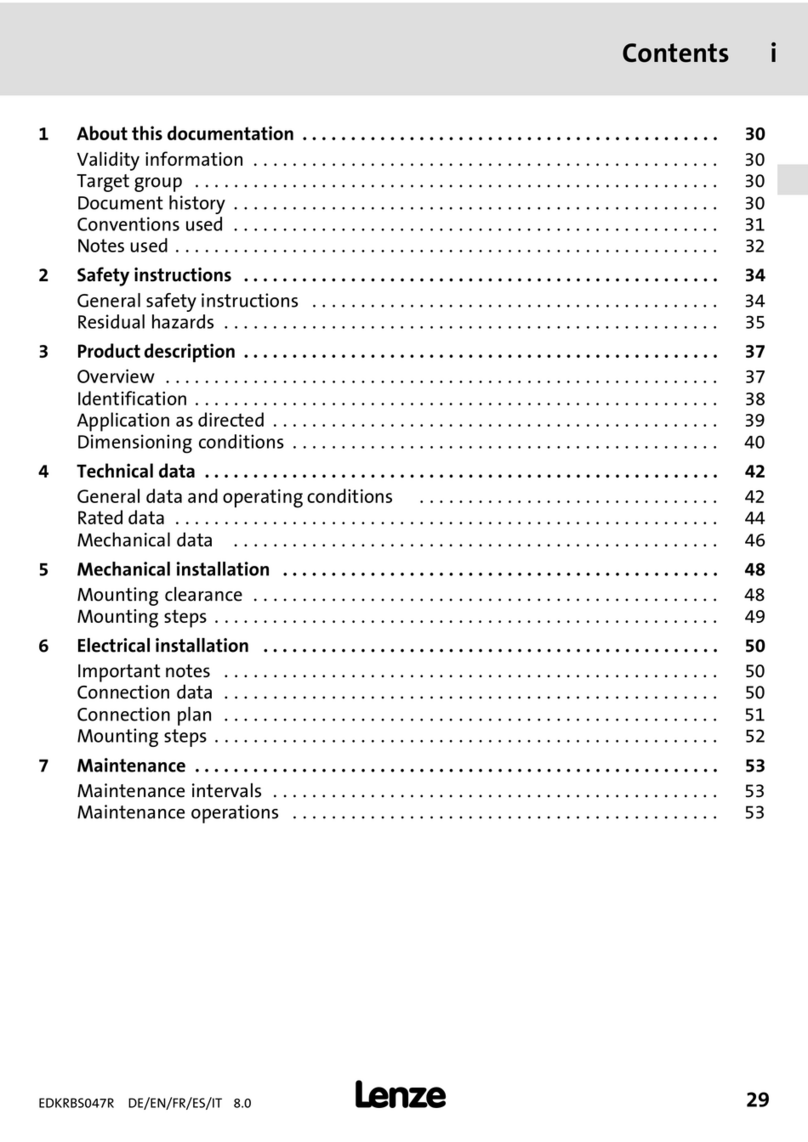

1 About this documentation

1.3 Terminology used

8Lenze · Controller-based Automation · PROFIBUS® Communication Manual · DMS 4.6 EN · 11/2016 · TD17

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

Code Parameter for parameterising or monitoring the field device. The term is also referred to as

"index" in common usage.

Controllers The Controller is the central component of the Lenze automation system which controls the

motion sequences by means of the operating system.

The Controller communicates with the field devices (inverters) via the fieldbus.

Engineering PC The Engineering PC and the Engineering tools installed serve to configure and parameterise

the system "Controller-based Automation".

The Engineering PC communicates with the controller via Ethernet.

Engineering tools Software solutions for easy engineering in all phases which serve to commission, configure,

parameterise and diagnose the Lenze automation system.

Lenze Engineering tools (22)

FAST By default, the Lenze FAST application software is installed on the Lenze Controller in the

"FAST runtime" version with "FAST Motion" for the central control of PLC applications.

Fieldbus node Devices integrated in the bus system as, for instance, Controller and inverter

Field device

GSD / GSE Device data base file (device description for PROFIBUS stations)

PLC Programmable Logic Controller

PLC Programmable Logic Controller (PLC)

Subcode If a code contains several parameters, they are stored in "subcodes".

In the documentation, the slash "/" is used as a separator between the code and the subcode

(e.g. "C00118/3").

In everyday language, the term is also referred to as "subindex".

Bus systems

CAN CAN (Controller Area Network) is an asynchronous, serial fieldbus system.

CANopen® is a communication protocol based on CAN. The Lenze system bus (CAN on board)

operates with a subset of this communication protocol.

CANopen® is a registered community trademark of the CAN user organisation CiA® (CAN in

Automation e. V.).

EtherCAT® (Ethernet for Controller and Automation Technology) is an Ethernet-based

fieldbus system which fulfils the application profile for industrial real-time systems.

EtherCAT® is a registered trademark and patented technology, licenced by Beckhoff

Automation GmbH, Germany.

Ethernet specifies the software (protocols) and hardware (cables, plugs, etc.) for wired data

networks. In the form of "Industrial Ethernet", the Ethernet standard is used in industrial

production systems.

On the basis of IEEE 802.3, standard Ethernet is specified by the Institute of Electrical and

Electronics Engineers (IEEE), USA.

EtherNet/IP™ (EtherNet Industrial Protocol) is an Ethernet-based fieldbus system that uses

Common Industrial Protocol™ (CIP™) to exchange data.

EtherNet/IP™ and Common Industrial Protocol™ (CIP™) are brand labels and patented

technologies, licensed by the ODVA user organisation (Open DeviceNet Vendor Association),

USA.

PROFIBUS® (Process Field Bus) is a widely used fieldbus system for the automation of

machines and production lines.

PROFIBUS® is a registered trademark and patented technology licensed by the PROFIBUS &

PROFINET International (PI) user organisation.

PROFINET® (Process Field Network) is a real-time capable fieldbus system based on Ethernet.

PROFINET® is a registered trademark and patented technology licensed by the PROFIBUS &

PROFINET International user organisation (PI).