Installation and maintenance

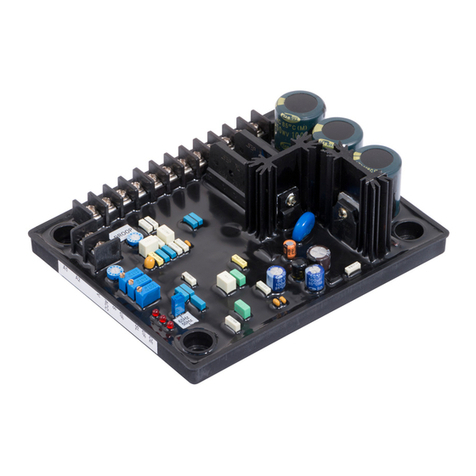

R438

A.V.R.

3971 en - 11.2006 / c

LEROY-SOMER

9

the voltage between E+ and E- (approx.

10V D.C.). The best response times are

obtained at the limit of the instability. If no

stable position can be obtained, try

disconnecting or replacing the ST2 jumper

(normal/fast).

h

) Check LAM operation :

ST5

closed.

i)

Vary the frequency (speed) around 48 or

58 Hz according to the operating

frequency, and check the change in voltage

from that observed previously (~ 15%).

j

) Readjust the speed of the unit to its rated

no-load value.

Adjustments in parallel operation

Before any intervention on the

alternator, make sure that the speed

droop is identical for all engines

.

k

) Preset for parallel operation (with C.T.

connected to S1, S2)

- Potentiometer P1 (quadrature droop) in

centre position.

Apply the rated load (cos

ϕ

= 0.8 inductive).

The voltage should drop by 2 to 3%. If it

increases, check that V and W and also S1

and S2 have not been reversed.

l

) The no-load voltages should be identical

for all the alternators intended to run in

parallel.

- Couple the machines in parallel.

- By adjusting the

speed

, try to obtain

0 KW

power exchange.

- By altering the voltage setting P2 on one

of the machines, try to cancel (or minimise)

the current

circulating between the

machines.

- From now on, do not touch the voltage

settings.

m

) Apply the available load (the setting is only

correct if a

reactive

load is available)

- By altering the

speed

, match the

kW

(or

divide the rated power of the units

proportionally)

- By altering the quadrature droop

potentiometer

P1

, match or divide the

currents

.

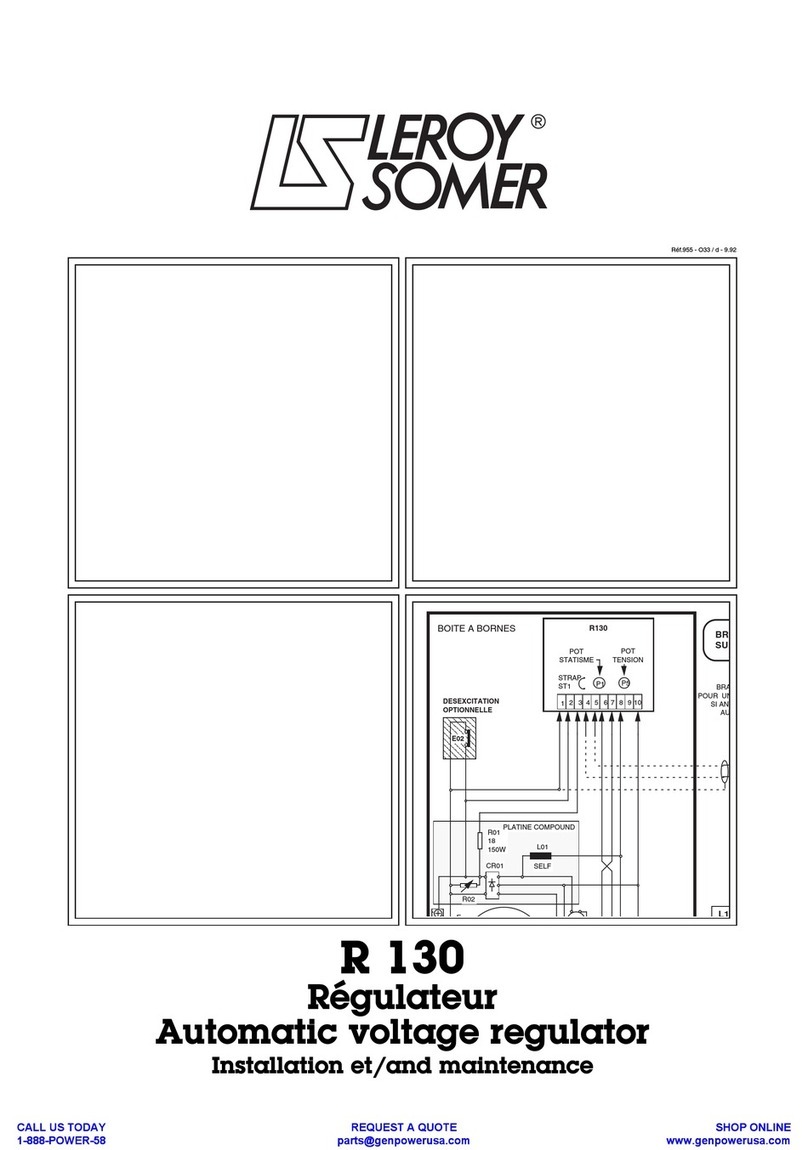

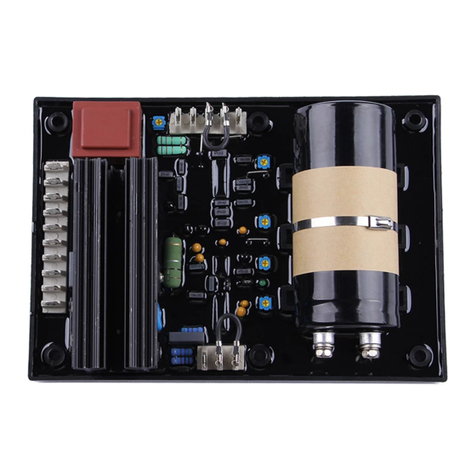

3.2.2 - Max. excitation setting (excitation

ceiling)

Static adjustment of the current limit,

potentiometer P5 (factory setting: 7.5 A,

fuse rating: 8 A - 10 seconds).

The maximum factory setting corresponds

to that of the excitation current required to

obtain a 3-phase short-circuit current of

approximately 3 IN at 50 Hz for industrial

power, unless otherwise specified(*).

A static method can be used to reduce this

value or adapt the Isc to the actual

operating power (derated machine), which

is safer for the alternator and the

installation. Disconnect power supply wires

X1,X2 and Z1,Z2 and the voltage reference

(0-110V-220V-380V) on the alternator.

Connect the mains power supply using a

transformer (200-240V) as indicated

(X1,X2 : 48V). Install a 10A D.C. ammeter

in series with the exciter field. Turn P5 fully

anti-clockwise and activate the power

supply. If there is no output current from the

AVR, turn potentiometer P2 (voltage)

clockwise until the ammeter indicates a

stable current. Switch the power supply off,

then on again, turn P5 clockwise until the

required max. current is obtained (no more

than 8 A).

Checking the internal protection

:

Open switch (D) : the excitation current

should increase to its preset ceiling, remain

at that level for

≥

10 seconds and then drop

to < 1A.

Depending on

the mains frequency Main

(50/60 Hz supply)

Max. excitation

Voltage

Field

~ 5 ohms

X2

Z1

X1

Z2

E+

E-

0V

110 V

220 V

380 V

50Hz 60Hz

P2

P3

P5

ST3

10 A CC/DC

48 V

110/220/380 V

R 438

ST4

A+

–

A

D

3971c_NotRegR438_en.fm Page 9 Jeudi, 9. novembre 2006 10:13 10