4

INSTALLATION AND MAINTENANCE

GEARLESS Z2 - Z3

A.C. Drive for elevators

LEROY-SOMER

3862 en - 07.2004 / a

4 - COMMISSIONING

BEFORE INSTALLATION

If the equipment has been stored for several months, it is

essential to check the following:

- the cleanliness of the interior and that there is no

condensation

- correct insulation between the phases and the earth terminal

on the motor (minimum 100M

Ω

at 500 V D.C. for 60 seconds)

after having disconnected all the electronic circuits if

necessary.

WARNING:

do not apply the megohmmeter to the terminals

of the thermal sensors as this may damage them.

If the required value is not reached, dry using internal or

external heating.

Drying using external heating

- place the motor in an oven at 70°C for at least 24 hours until

the correct insulation is achieved. (100M

Ω

)

- Take care to increase the temperature gradually to clear the

condensation.

- After drying, during the cooling phase, check the insulation

value regularly, as it will initially tend to fall then rise.

Drying using internal heating

- Test to be carried out with the brakes released.

- Connect motor windings V and W in parallel in relation to U.

(see drawing below)

- Read off the resistance between U and V//W.

- Apply a

low voltage

D.C. current to them (to obtain 10% of

the rated current calculated using the resistances of the

winding), increase the voltage until 50% of the rated current

is reached.

- Maintain the power for 4 hours. The temperature of the

motor should increase slightly.

CAUTION: The pulley will move slightly on power-

up (angular setting of the rotor in relation to the

stator).

4.1 - INSTALLATION

The installation must comply with the characteristics of the

motor indicated on the nameplate (see section 1).

It must include electrical safety devices.

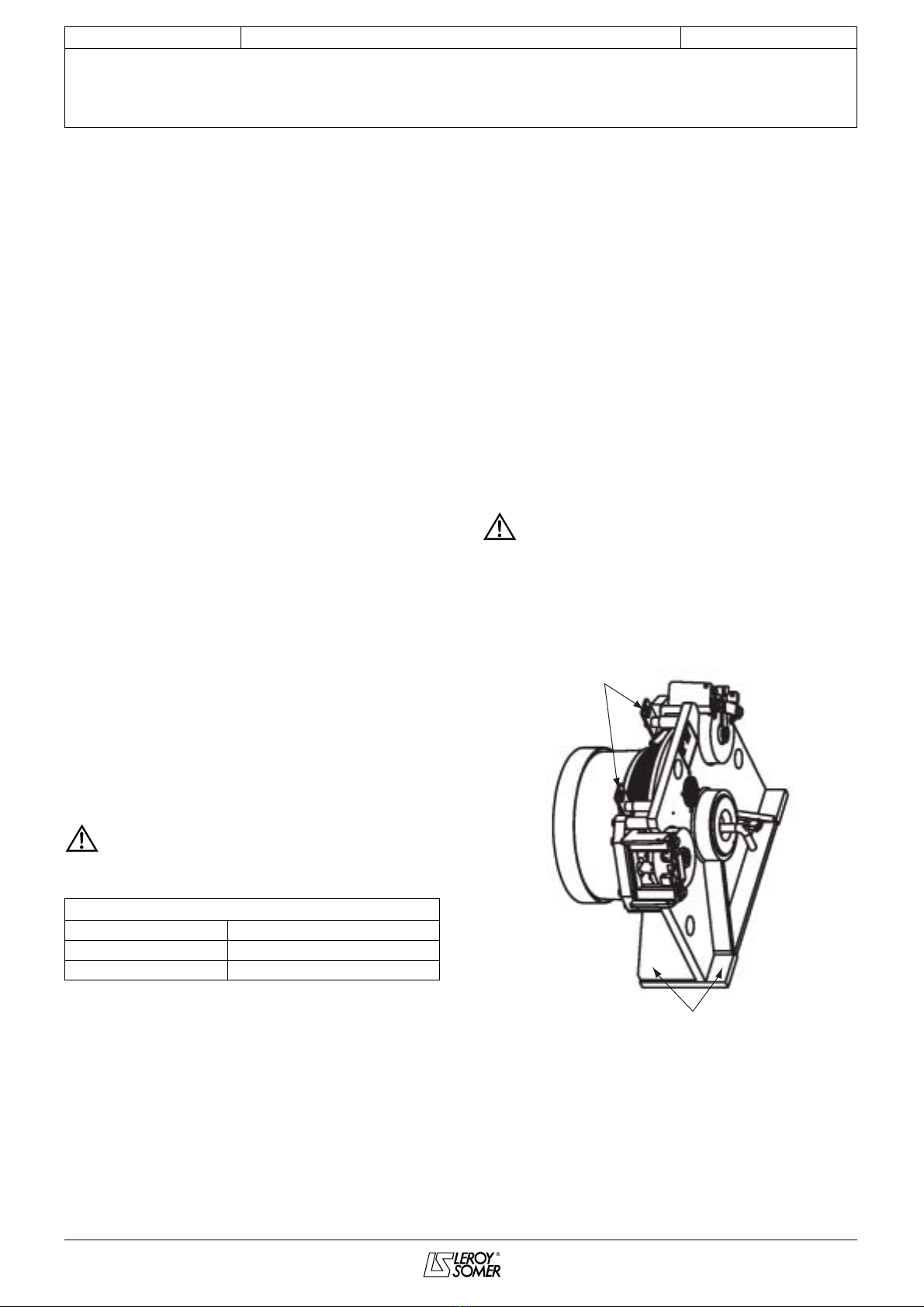

Check that the handling equipment (slings, etc.) are suitable

for the weight of the machine.

Use the attachment points provided on the machine.

Check that the cables are correctly positioned so that they are

not damaged.

Provide the necessary mechanical protection devices to

prevent people working on the machine becoming caught or

trapped by the pulley and/or the cables.

The motors must be installed in such a way that the cooling

air (not too damp, dust-free, and containing no vapour or

corrosive gas) circulates freely.

4.1.1 - Cleaning

- Release the brake using the manual release system.

- Remove the protective varnish from the pulley grooves.

CAUTION: Do not use abrasive equipment. Use

only a cloth soaked in alcohol. Care must be taken

not to get any alcohol or grease on the brake disk.

WARNING:

use the alcohol in a well ventilated area.

Z2-Z3 Fabricated steel shield

Motor connection for drying the winding

Phase connection

Power supply (-) U

Power supply (+) V + W (serial)

Anchoring points

for lifting

Fixing screws