Leuze electronic MSI 420.TMC-03 3

2 System overview

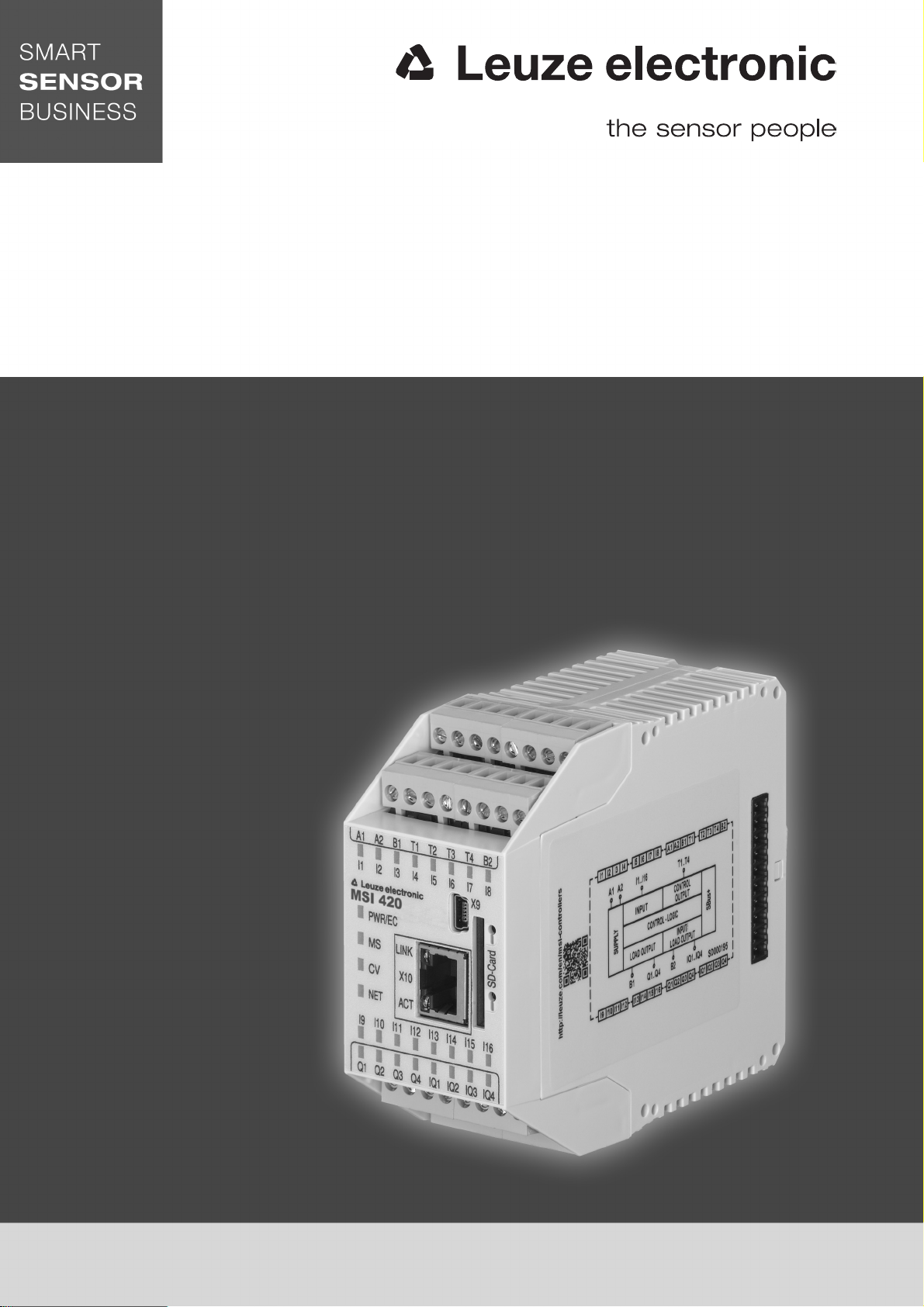

The

TMC 66 Legacy

system is based on the MSI 400 safe compact control from Leuze electronic. The

system is a substitute for the TMC 66 (Leuze electronic article no. 50082121) and is used only as a

replacement solution.

The solution essentially consists of a hardware component and software functionality specifically config-

ured for this application. The latter emulates the original behavior of the TMC 66, thus enabling simple

replacement of the old device.

The software functionality is already stored on the supplied memory card on delivery. The program has

already been verified so that the program sequence is executed automatically as soon as the

MSI 420.TMC-03 is connected to the supply voltage and has completed a self test.

Owing to the preconfigured memory card, it is not necessary to make any changes to the logic program

during commissioning.

If the memory card needs to be changed, this must always be done by a Leuze electronic service techni-

cian.

If Leuze electronic explicitly instructs you to change the memory card (e.g. in the event of an update), this

can be done by a competent person, taking the relevant work instructions into consideration.

2.1 Features

Four different operating modes are available:

• Operating mode 1: Start/restart interlock active; contactor monitoring inactive

• Operating mode 2: Start/restart interlock inactive; contactor monitoring inactive

• Operating mode 3: Start/restart interlock active; contactor monitoring active

• Operating mode 4: Start/restart interlock inactive; contactor monitoring active

The respective operating mode is selected by means of a wire bridge, see table 4.2 "Selection of operating

mode".

Three signal outputs for indicating the status (for details, see chapter 5 "Diagnostics messages")

•Error

• Safety on

• Error indication

NOTE

During development of the replacement solution, great importance was placed on 1:1 exchangeability

(wiring and functionality) with the TMC 66. Nevertheless, some aspects with respect to the handling and

system behavior of the replacement solution differ from the TMC 66. The main differences are described

at the appropriate point in this document.

NOTE

When designing new systems with muting, we recommend using our MLC SPG (Smart Process Gating).

This system will enable you to completely dispense with muting sensors. This will not only save space,

but will also reduce the amount of mounting and installation work required. We would be glad to advise

you in a personal consultation.

NOTE

The supplied software functionality was developed and tested in accordance with the directives appli-

cable for so-called SRASW (Safety-Related Application Software), as defined in ISO 13849-1.

ATTENTION

Before connecting the MSI 420.TMC-03 to the supply voltage, make sure that the device has been

connected in accordance with the supplied wiring plan.

Commissioning may only be performed by a competent person and following the steps given in the

section Electrical connection and commissioning (see chapter 4 "Electrical connection and commis-

sioning").