System overview

Leuze electronic RS4/AS-i 7

TNT 35/7-24V DEUTSCHENGLISHFRANÇAISITALIANOESPAÑOLNEDERLANDS

2 System overview

The RS4 area scanner is an active optoelectronic protective device (AOPD) of type 3. It

polls the protective field that has been selected by the setting of parameters on a

continuous basis, and when the protective field is violated switches off its OSSD safety

switching outputs (OSSD = output signal switching device), so checking the hazardous

movement. While the system is in operation, it is possible to switch between up to four

parameterised protective fields and warning fields by means of local sensor signals.

Depending on the parameter settings, the scanner may emit a non-safety-related warning

signal if the front pane becomes too dirty and/or in the case of a warning field (that has

likewise been parameterised) being violated.

In view of its integrated AS-i Interface, the RS4/AS-i can be connected to the AS-Interface

bus system. If a person or obstacle is situated within the protective fields that have been

defined earlier, a safety-related switching function will be triggered and the machine that is

protected by means of the AS-Interface and the AS-i safety monitor will be brought into a

safe state. This switching function will only be reset when the protective field is clear,

irrespective of the operating mode, which may be automatic or may involve acknowledge-

ment by way of the AS-i safety monitor.

2.1 Short description of the RS4/AS-i

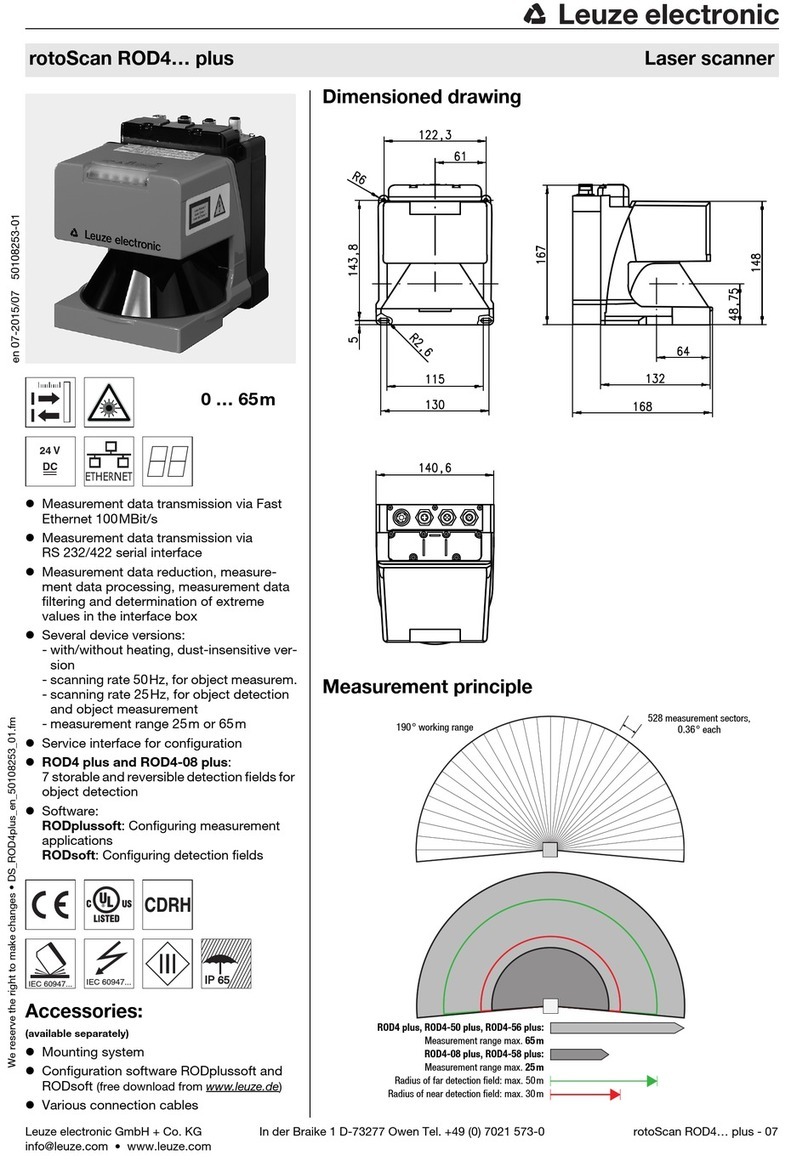

The RS4/AS-i area scanner sends out extremely short laser pulses, and measures the time

between the impacting of a pulse on an object and its being reflected back to the receiver of

the RS4/AS-i. The length of time enables the device to calculate the distance between the

object and the RS4/AS-i.

The polling unit in the scanner rotates, and sends out / receives a laser pulse at intervals of

0.36°. In this way a sector of a circle of up to 190° can be polled, the RS4/AS-i being

located at the midpoint. The protective field that is to be monitored is limited by a user-

defined curve around the scanner, the maximum distance from this to the midpoint of the

scanner being 4 metres. If an object is detected between this boundary line and the

scanner, thus violating the protective field, the scanner will switch off its safety-related

OSSD output, and the status of the OSSDs will be transmitted to the AS-i safety monitor by

way of the AS-i system in the form of a cyclic data sequence; having been notified of the

violation of the protective field, the monitor will bring the hazardous movement to a halt.

In addition to the safety-related protective field, a non-safety-related warning field can be

parameterised; when this is violated the system will not be switched off, but a warning

signal will be given. This will likewise be included in the data telegram that is exchanged

cyclically with the AS-i bus master and can be called up at will.

Achtung!

Although the data transfer is safety-related, the warning signal should not be used in a

safety-related manner, as it is not delivered by the scanner as a safe signal.

The protective field and the warning field together constitute a pair of protective fields. They

are always activated jointly, and a maximum of four protective fields may be selected at any

time. All pairs of protective fields, as well as the permissible modes of switching between

them, will be adapted to the given application when the system is first put into operation.

When the system is operational, switching between protective field pairs is managed by

local sensor signals.