Specifications

6 DB 112 B Leuze electronic

4 Specifications

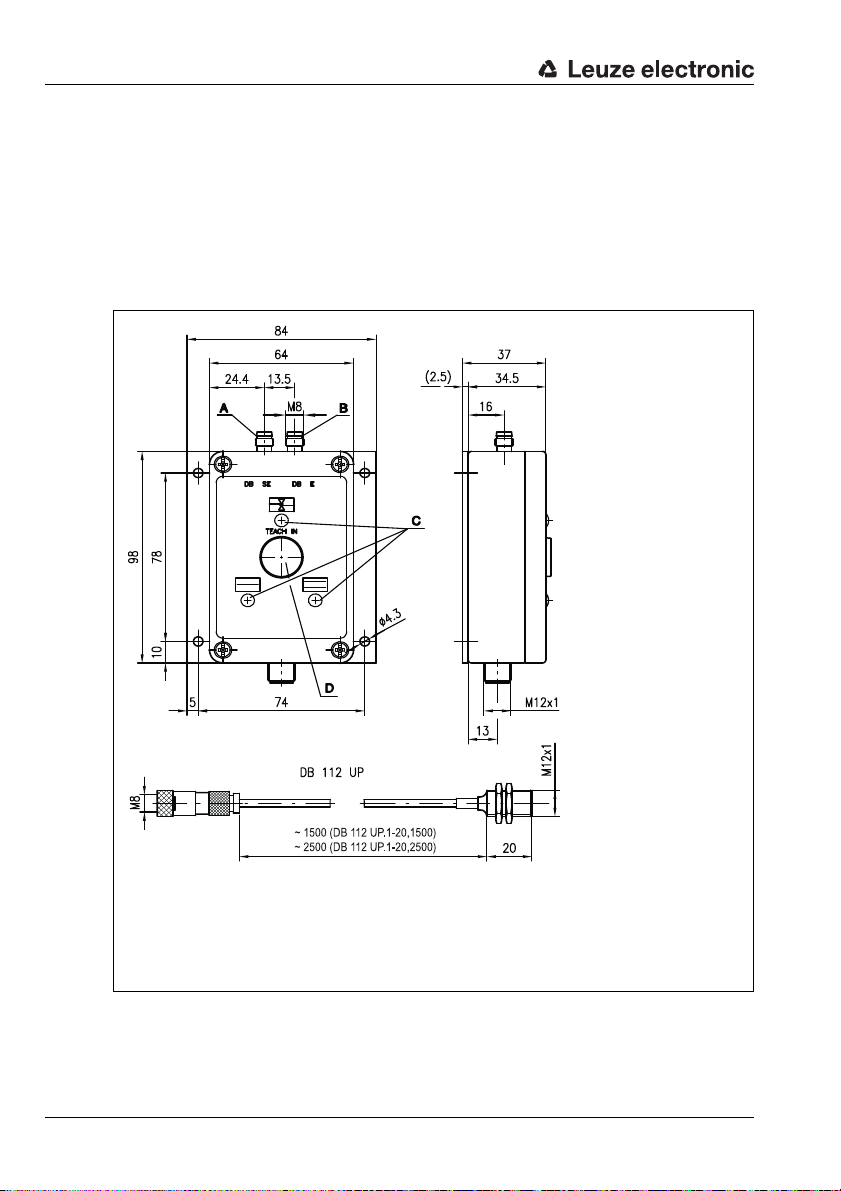

Technical data for sensor DB 112 UP

Technical data for analysis amplifier VDB 112 B/…

Sensor data

Operating range 15 … 30mm

Converter frequency 300kHz ±5%

Ultrasonic lobe approx. 12°

Mechanical data

Housing nickel-faced brass

Weight 30g

Connection type 1.5/2.5m cable with M8 connector,

3-pin, bending radius r > 25mm

Timing

Switching frequency 200Hz

Input pulse min. 5ms

Delay before start-up ≤300ms

Electrical data

Operating voltage UB1)

1) For UL applications: only for use in "Class 2" circuits according to NEC.

18 … 30VDC (incl. residual ripple)

Residual ripple ≤15% of UB

Open-circuit current ≤75mA

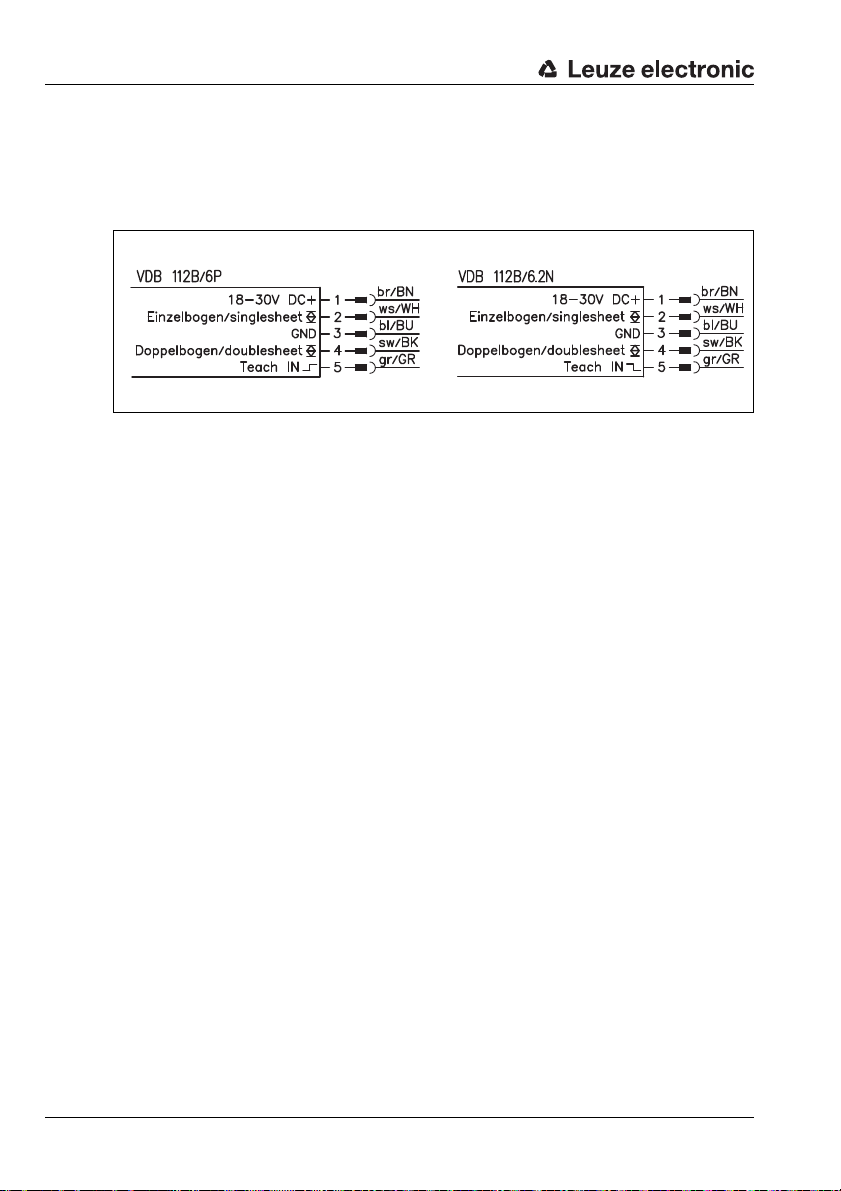

Switching output 2 push-pull switching outputs 2)

2) Function: …/…P = active high (+24V); inactive low (0V),

…/…N = active low (0V); inactive high (+24V).

The push-pull switching outputs must not be connected in parallel

Function single sheet detected, or ≥ 1 sheet

double sheet detected, or ≥ 2 sheets

Signal voltage high/low ≥(UB- 2V)/≤2V

Output current max. 100mA per output

Teach input Rin =10kΩ

TEACH-IN active/not active 3)

3) Setting the Teach IN input disables the TEACH IN button (see page 10)

…/…P (PNP): ≥10V / ≤2V or not connected

…/…N (NPN): ≤2V / ≥10V or not connected

TEACH IN duration max. 100ms

TEACH IN delay 4)

4) Only applies for automatic calibration during sheet movement (automatic teach)

approx. 300ms

Indicators

LED green A double sheet testing unit ready

LED A yellow teach-in process

LED A red flashing error (see chapter 9)

LED yellow B single sheet detected

LED red C double sheet detected

Mechanical data

Housing aluminium, black powder-coated

Weight 400g

Connection type M12 connector, 5-pin

Environmental data

Ambient temp. (operation/storage) 0°C … +50°C / -40°C … +70°C

Protective circuit 5)

5) 1=transient protection, 2=polarity reversal protection, 3=short circuit protection

1,2,3

VDE safety class III

Protection class IP 65

Standards applied EN 60947-5-2

Certifications UL 508, C22.2 No.14-13 1) 6)

6) These proximity switches shall be used with UL Listed Cable assemblies rated 30V,

0.5A min, in the field installation, or equivalent (categories: CYJV/CYJV7 or PVVA/PVVA7)