Description

Contents

Page

1Description . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Design and Function . . . . . . . . . . . . . . . . . . . 2

1.2 Standard Specification . . . . . . . . . . . . . . . . . . 3

1.3 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Ordering Data . . . . . . . . . . . . . . . . . . . . . . . . 6

2Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Setting the Mains Voltage . . . . . . . . . . . . . . . 7

2.2 Connecting the TURBOVAC . . . . . . . . . . . . . . 7

2.3 Connecting the Forevacuum Pump . . . . . . . . 7

2.4 TURBOTRONIK NT 340 M & MA without

temperature control (TCU):

Connecting the Cooling, Venting Device

and the Flange Heater . . . . . . . . . . . . . . . . . 8

2.5 TURBOTRONIK NT 340 MA with

temperature control (TCU):

Connecting the Temperature Control

and the Forevacuum Valve. . . . . . . . . . . . . . 10

2.6 TURBOTRONIK NT 341 MA:

Connecting the Temperature Control

and the Forevacuum Valve. . . . . . . . . . . . . . 12

2.7 Connecting the Interface . . . . . . . . . . . . . . . 14

2.8 Connecting the Remote Control . . . . . . . . . . 14

2.9 Modifying the Relay “Failure” (Option) . . . . . 16

2.10 Installing the TURBOTRONIK . . . . . . . . . . . 16

3Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 Start-up of the TURBOVAC . . . . . . . . . . . . . 18

3.3 Bakeout of the TURBOVAC . . . . . . . . . . . . . 18

3.4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Shut-down of the TURBOVAC . . . . . . . . . . . 19

3.6 Venting of the TURBOVAC . . . . . . . . . . . . . . 19

3.7 Power Failure - Linecord Interruption . . . . . . 19

3.8 Shut-down of the TURBOTRONIK . . . . . . . . 20

3.9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 21

EC Conformance Declaration . . . . . . . . . . . . 22

Warning

Indicates procedures that must be strictly observed to prevent

hazards to persons.

Caution

Indicates procedures that must be strictly observed to prevent dam

age to, or destruction of the appliance.

Figures

The references to diagrams, e. g. (2/10), consist of the Fig. No. and

the Item No.in that order.

We reserve the right to alter the design or any data given in these Op

erating Instructions.

The illustrations are not binding.

1 Description

1.1 Design and Function

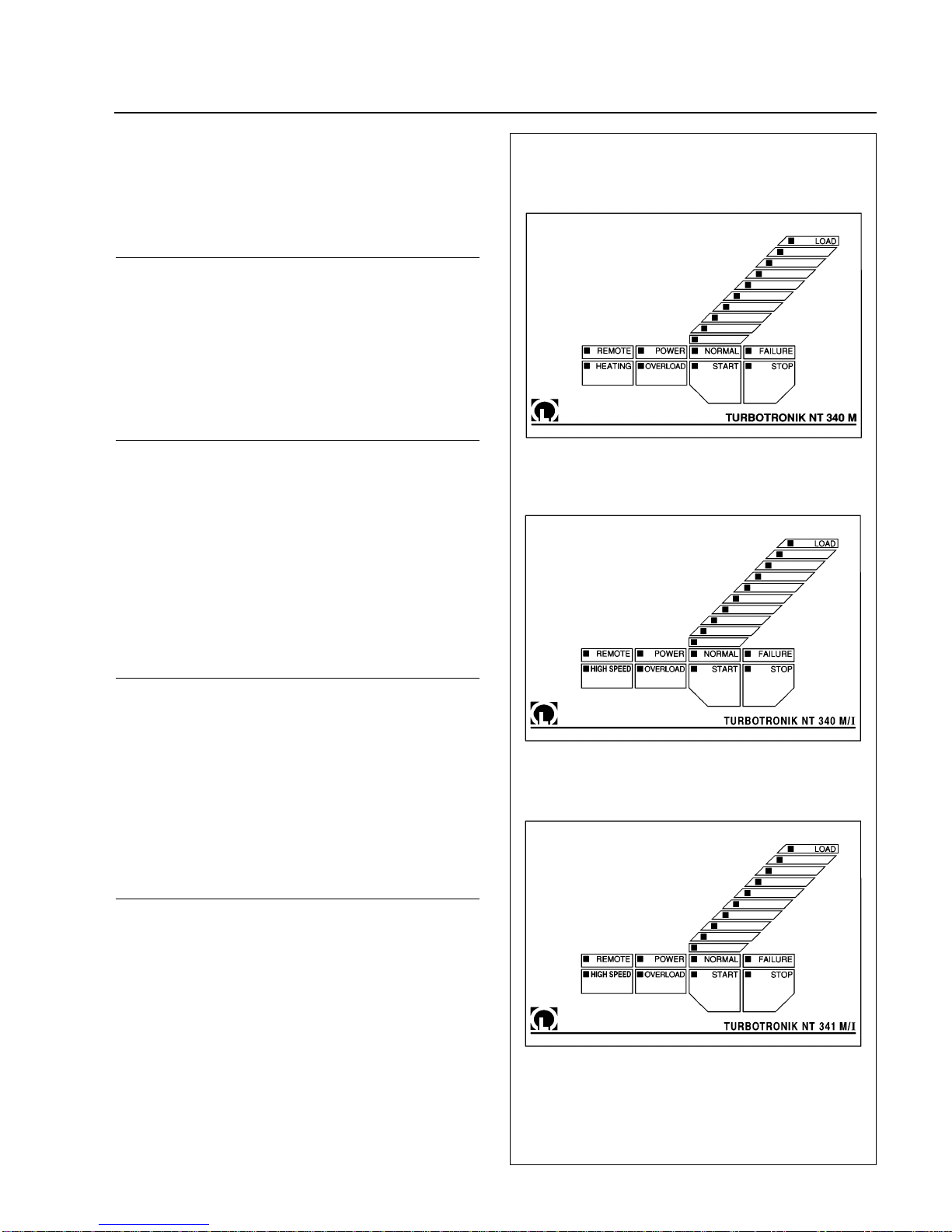

TheTURBOTRONIK NT 340 M, NT 340 MA, and NT 341

MA are electronic frequency converters.They operate

turbomolecular pumps TURBOVAC.

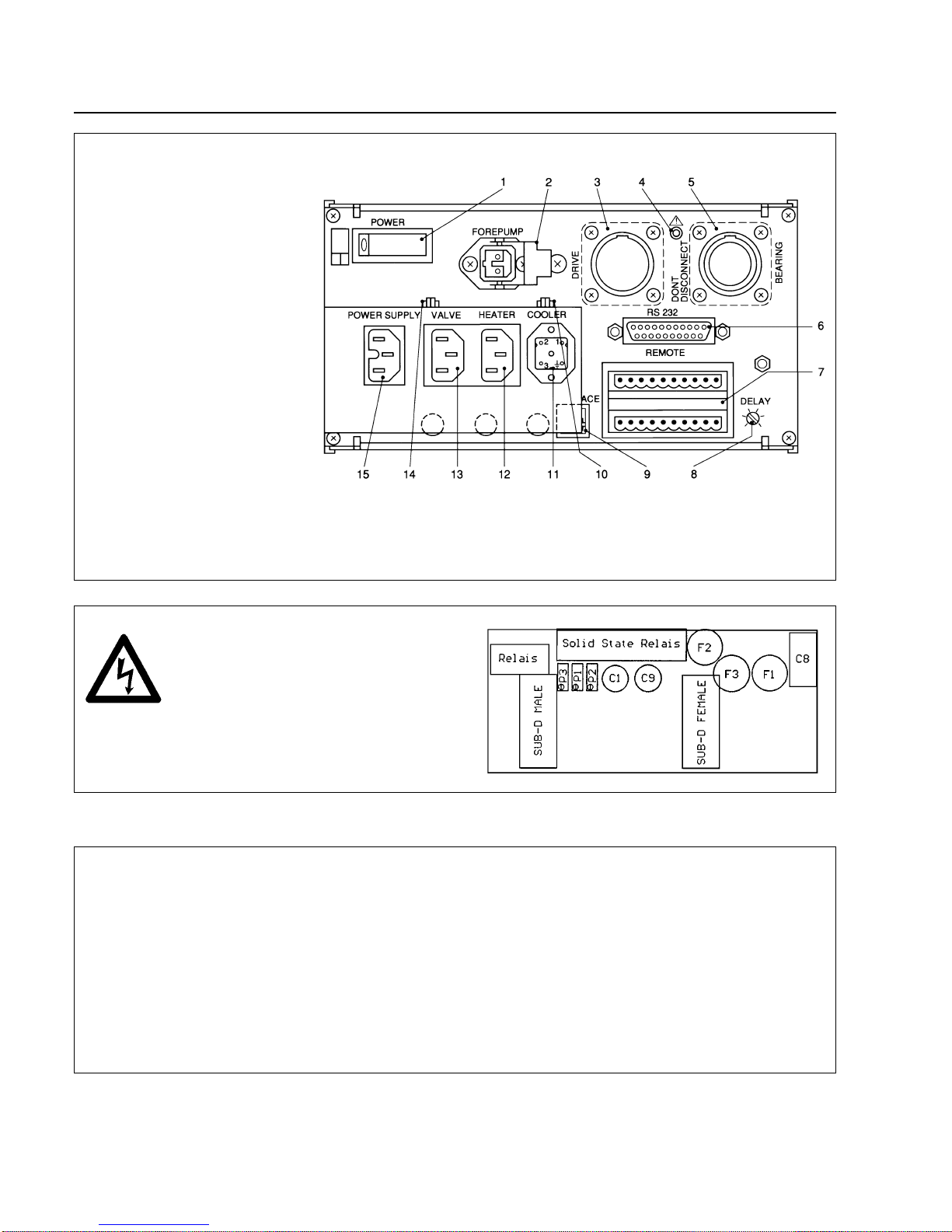

The TURBOTRONIK NT 340 MA and NT 341 MA are

prepared for operation with an additional temperature

control unit. This temperature control unit is part of a

temperature control which maintains the temperature of

the TURBOVAC within a narrow control range.

The TURBOTRONIK converts the single-phase mains

voltage into a regulated DC power supply.The unit’s

electronic circuitry then switches this DC power supply

onto the four stator windings of the TURBOVAC’s com-

mutatorless DC motor in a cyclical sequence.

This electronic switching system uses Hall probes, and

replaces the commutator normally found in DC motors.A

digital controller keeps the speed of the motor constant.

The TURBOTRONIK also powers and regulates the

magnetic bearing unit. Switching the motor to the gen-

erator mode keeps the magnetic bearing unit in operati-

on even in case of a mains power failure.

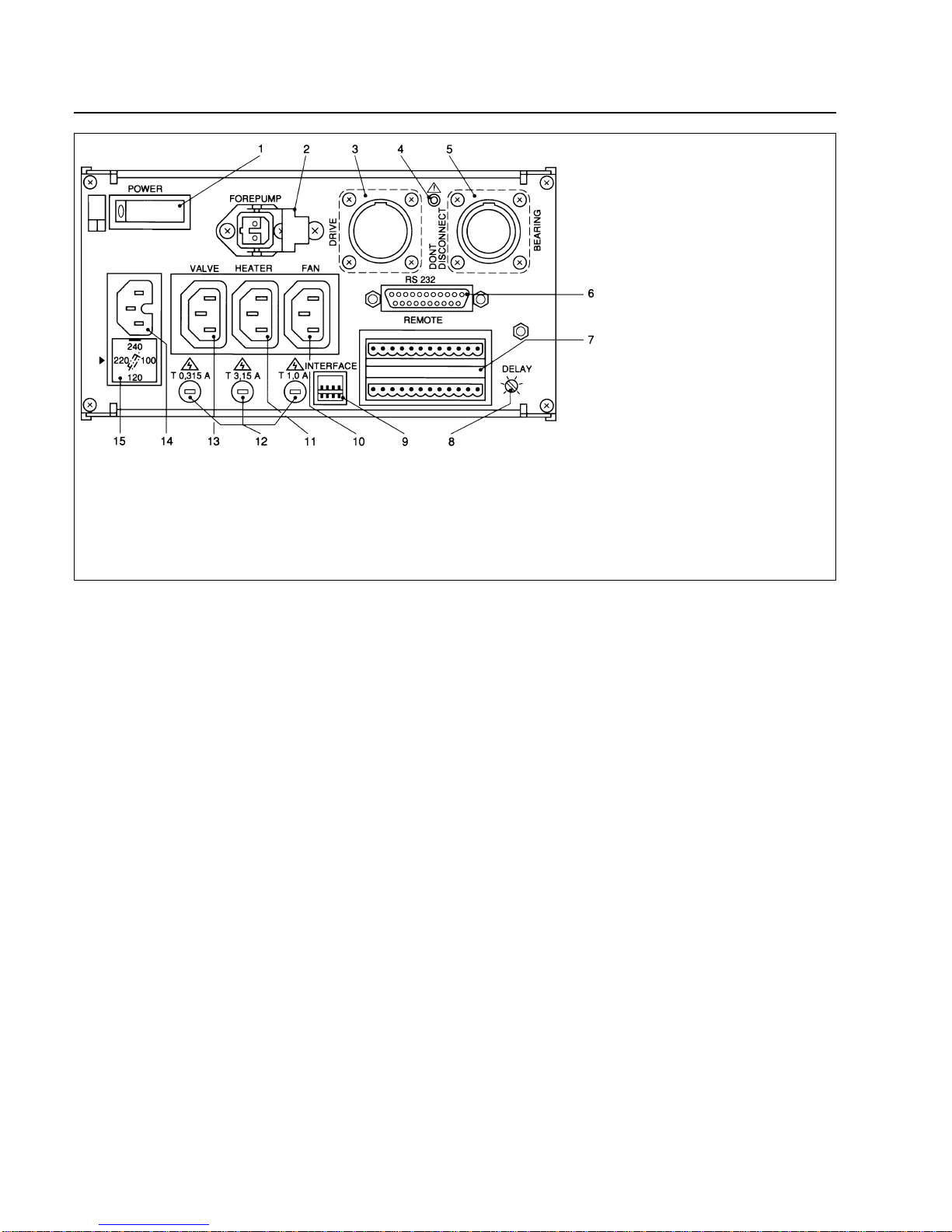

Both the TURBOTRONIK and the TURBOVAC are fitted

with sensors to ensure reliable operation of the entire

system. External control and monitoring equipment e.g.

the LEYBOTRONIK I can be connected via floating plug-

and-socket terminals located at the rear of the TUR-

BOTRONIK. Both the remote control unit and the lines

for the pump system’s status signals are connected here.

These terminals also provide connections for controlling

the forepump, the heater and valves.

An RS-232 interface provides a further control and mon-

itoring option.

The unit also has a counter-current braking system for

slowing down the pump when it is shut down.

2GA 05.218/3.02 - 11/97