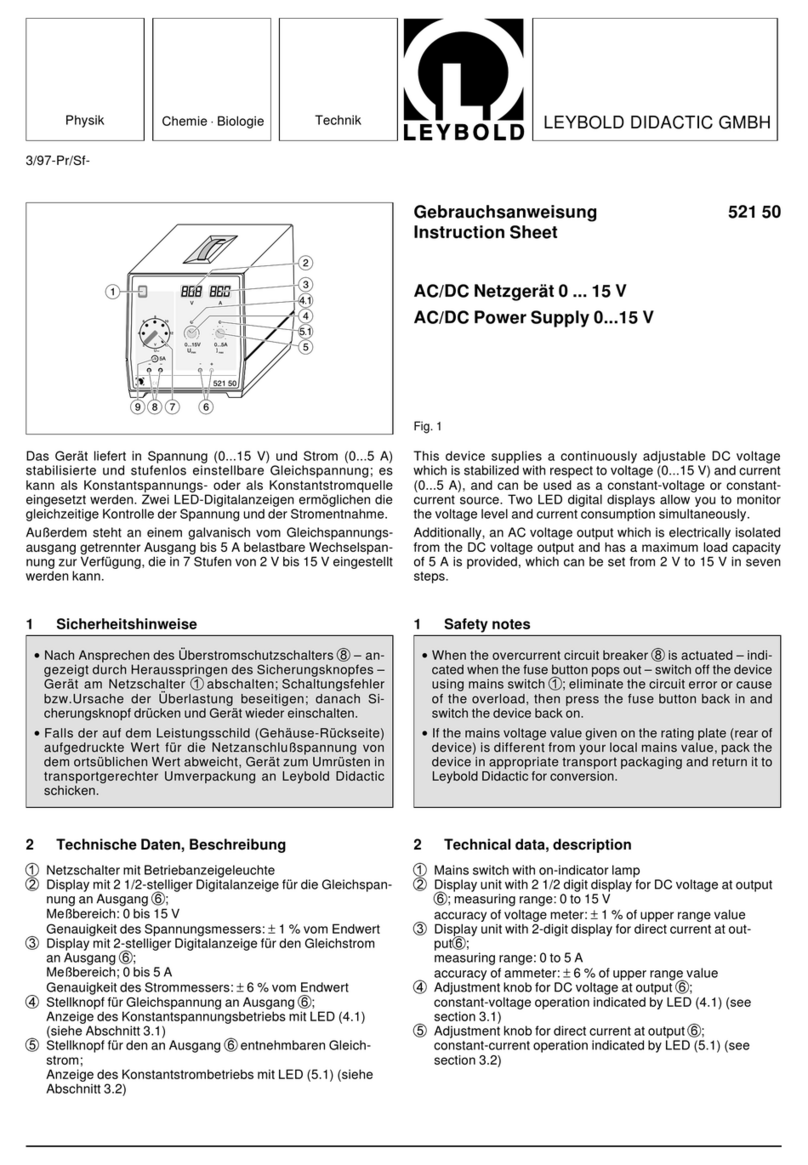

2

2 Description

The equipment set MTS 7.4.1 contains a completely assembled Gunn oscillator (c.f. Fig. 1) for a

fixed frequency of 9.40 GHz.This oscillator was especially developed for the requirements of the

training system.

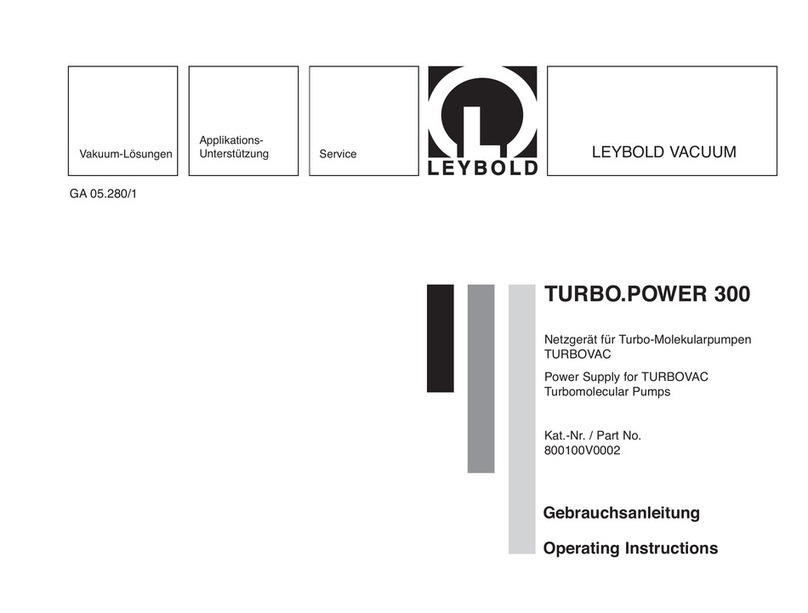

(a) This device can be disassembled into four parts, and is thus well suited for experiment pur-

poses. These four parts are connected using LD quick connectors and are: the Gunn-diode

module, the housing rear panel, a diaphragm, and a adapter (see Fig. 2).

(b) In the training system MTS 7.4.6, it can be modified into a mechanically tuneable oscillator

in the frequency range of 8.5 to 12.4 GHz, using a moveable short.

The function of the Gunn oscillator, which is explained in more detail and practically applied in

MTS 7.4.2, is based on the reduced damping of the cavity resonator using the Gunn diode.

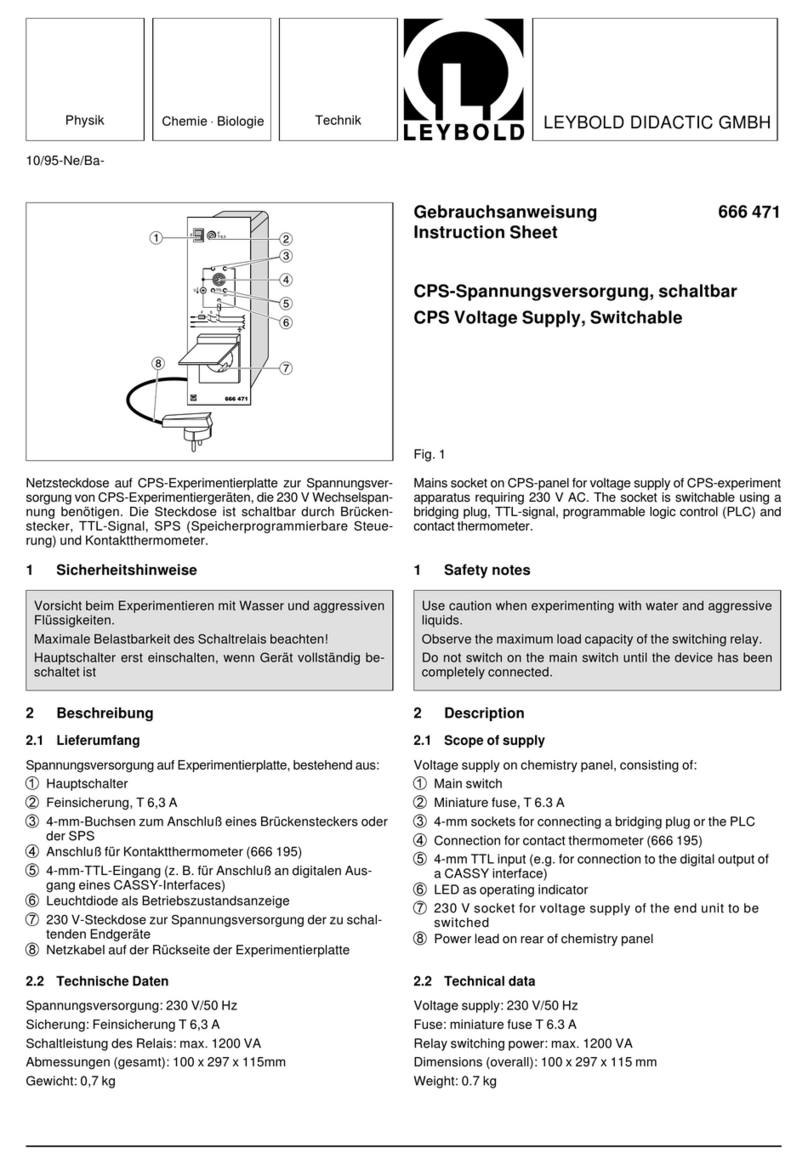

The current of the DC circuit (Fig. 3) flows via the internal conductor (negative pole) of the coaxi-

al BNC socket, the internal conductor of the coaxial low-pass filter and the upper section of the

metal post to the Gunn diode and from there via the lower section of the metal post to the hou-

sing.The heat of the Gunn diode is drained to the housing via the metal post.

The design of the low-pass filter prevents a portion of the microwave power generated in the

Gunn diode from being diverted to the DC circuit; this can be deduced in Fig. 3. It consists of two

cascaded coaxial line segments with considerably different characteristic impedances, which

just reach l/4 at an operating frequency of 9.40 GHz.Thus the microwave signal is almost shor-

ted at the transition point between the coaxial line and the waveguide.

Before the oscillator was delivered, fine tuning of the frequency was carried out by changing the

penetration depth of the stub using the dielectric tuning screw.Therefore, this penetration depth

may not be altered by the user.

Fig. 2: Components of the Gunn oscillator

1Gunn diode module with:

2Metal post (incl. Gunn diode)

3Dielectric tuning screw

4BNC socket

5Rear housing wall

6Diaphragm with aperture

7Adapter