Description

Contents

Page

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Compatibility with pumped media. . . . . . . . . . . . . 2

1.1 Standard equipment. . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Order data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Operating environment. . . . . . . . . . . . . . . . . . . . . 9

2.2 Connecting the pump to the vacuum chamber . . 9

2.3 Making the forevacuum connection . . . . . . . . . . 12

2.4 Connecting the cooling. . . . . . . . . . . . . . . . . . . . 12

2.5 Connecting the purge gas and airing device . . . 12

2.6 Connecting the TURBOTRONIK . . . . . . . . . . . . 13

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Switching on. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Bakeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Switching off. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Removing the pump from the system . . . . . . . . 16

4 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Service by LEYBOLD. . . . . . . . . . . . . . . . . . . . . 17

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 18

EC Manufacturer’s Declaration . . . . . . . . . . . . . 19

Conventions used in these instructions

Illustrations

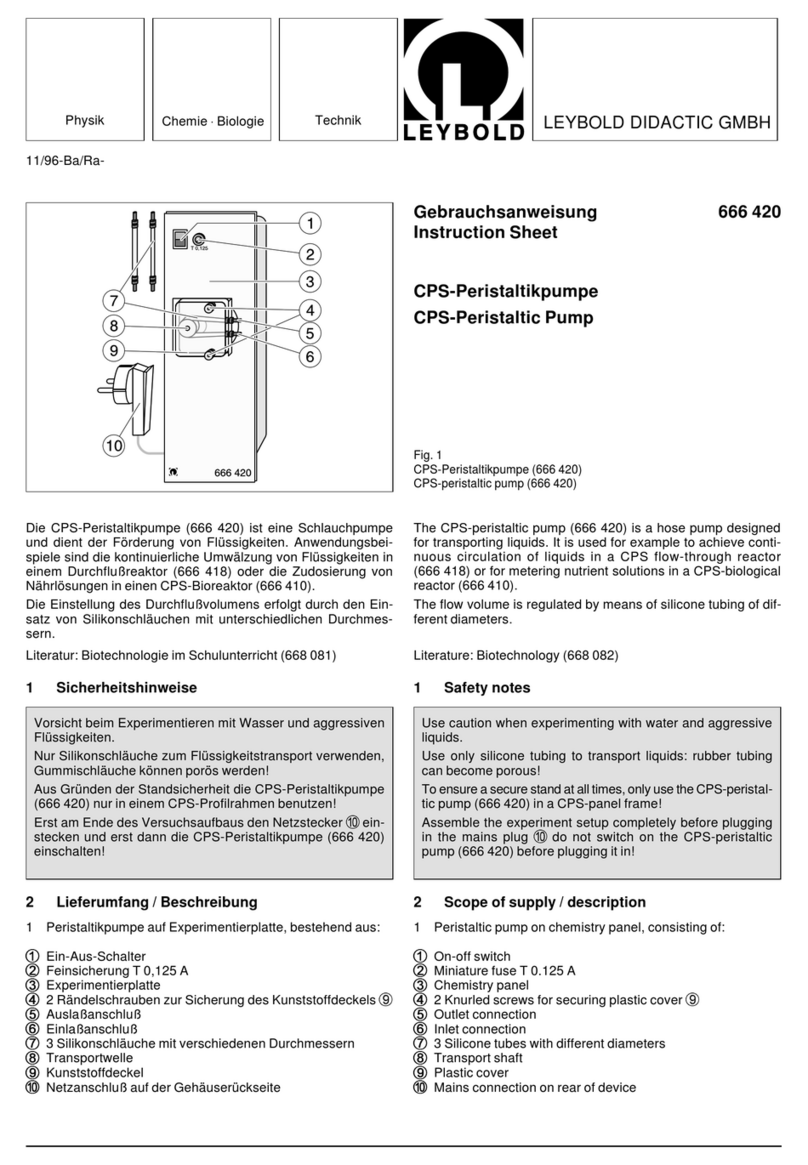

The references to diagrams, e.g. (2/10), consist of the figure

number and the item number, in that order.

Warning

This indicates procedures and operations which must be strict-

ly observed to prevent hazards to persons.

Caution

This indicates procedures and operations which must be strict-

ly observed to prevent damage to or destruction of the unit.

We reserve the right to change at any time the design and data

given in these operating instructions.

The illustrations are approximate.

1 Description

The TURBOVAC models 50 to 1000 are turbomolecular

pumps featuring grease-lubricated bearings. These

units are engineered to pump vacuum chambers down

to pressures in the high-vacuum range. A TURBOTRO-

NIK frequency converter and a forevacuum pump are re-

quired for the operation of the TURBOVAC.

These units are not suitable for operation without a fore-

vacuum pump.

Compatibility with pumped media

Turbomolecular pumps are not suitable for pumping

either gases which contain dust particles or liquids.

Turbomolecular pumps without a purge gas feature are

suitable only for moving air or inert gases. They are not

suitable for pumping aggressive or reactive gases.

TURBOVAC versions identified with a “C” in the model

number are equipped with this purge gas feature, it pro-

tects only the bearing area and the motor in the TURBO-

VAC.

Some media (such as aluminum trichloride) can sublime

inside the pump and form deposits. Thick deposits re-

duce the play between moving parts to the point that the

pump could seize. In some processes deposits can be

prevented by heating the pump. Please consult with us

in case such problems arise.

Corrosive gases (such as chlorine) can destroy the

rotors.

During operation the pressure inside the TURBOVAC is

so low that there is no danger of ignition (at pressures

below about 100 mbar, 75 Torr). A hazardous condition

will be created if flammable mixtures enter the hot pump

at pressures above 100 mbar (75 Torr). During operati-

on the pump can reach temperatures as high as 120°C

(248 °F). Sparks could occur in case of damage to the

pump and these could ignite explosive mixtures.

We would be glad to consult with you as regards the

media which can safely be handled with this unit.

Warning Never expose any parts of the body to the

vacuum.

Caution Any tampering within the pump or modifica-

tions to the mechanical or electrical compo-

nents of the pump, will void any liability and

warranty claims.

2GA05118_1302 - 01/2004