2.1 Features

•Pt-100resistorsastemperaturesensors

•twomeasurementchannels

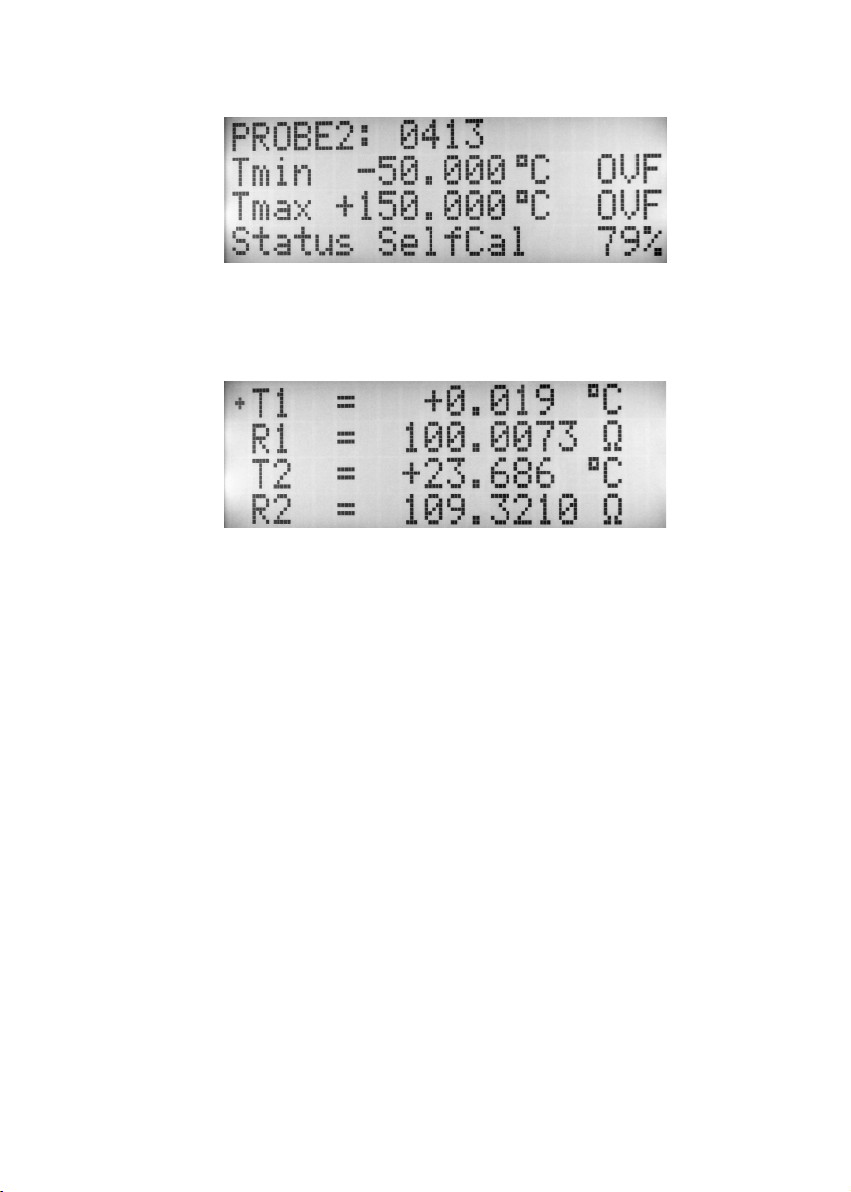

•highresolution(0,001°C)

•temperaturemeasurementaccuracyupto±0.007°C(specialon-demandversion)

•internalautocalibrationcircuitry

•easytooperate

•enclosuremadeofdurablematerials

•ThermometerUtilitysoftwareinpriceoftheproduct-conguration,acquisitionofmeasu-

rements

•largedisplay

•calibrationdataprotectedbyatriplememorywritesystem

•possibilityofintroductionofuser’sCallendar-VanDusencoefcients

•temperaturedisplayedin°C,°F,K

•displayofadditionalparameter:gradient,resistance,temperaturedifference

•USBandRS-232interfaces

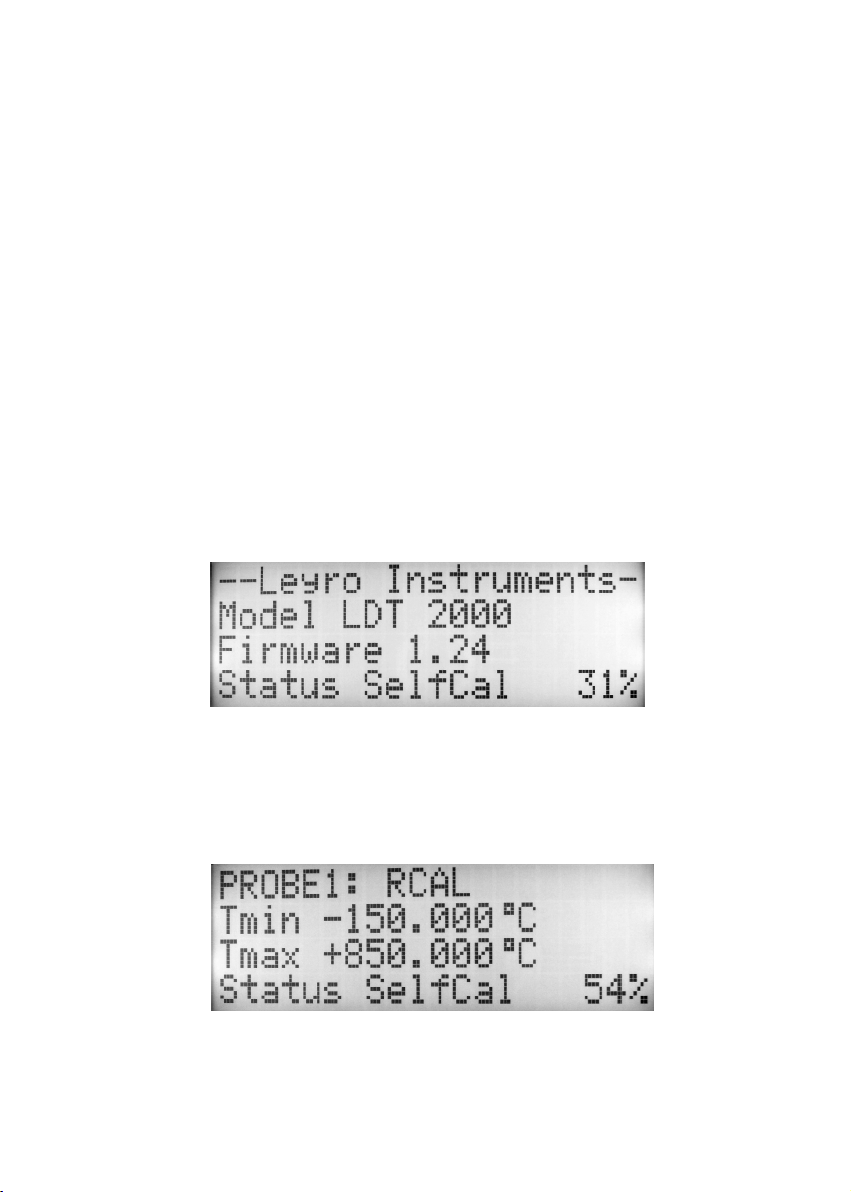

the means of Current Reversal technique. The autocalibration sequence is a background

task performed continuously. The LDT 2000 has been designed to make operating as

simpleaspossible.Anadvancedcongurationanddataacquisitionoptionsareavailable

by the means of PC interface and suitable PC software. A large illuminated LCD display is

capable of indicating several parameters simultanously.

Temperature measurement

range

Resolution

Acuraccy

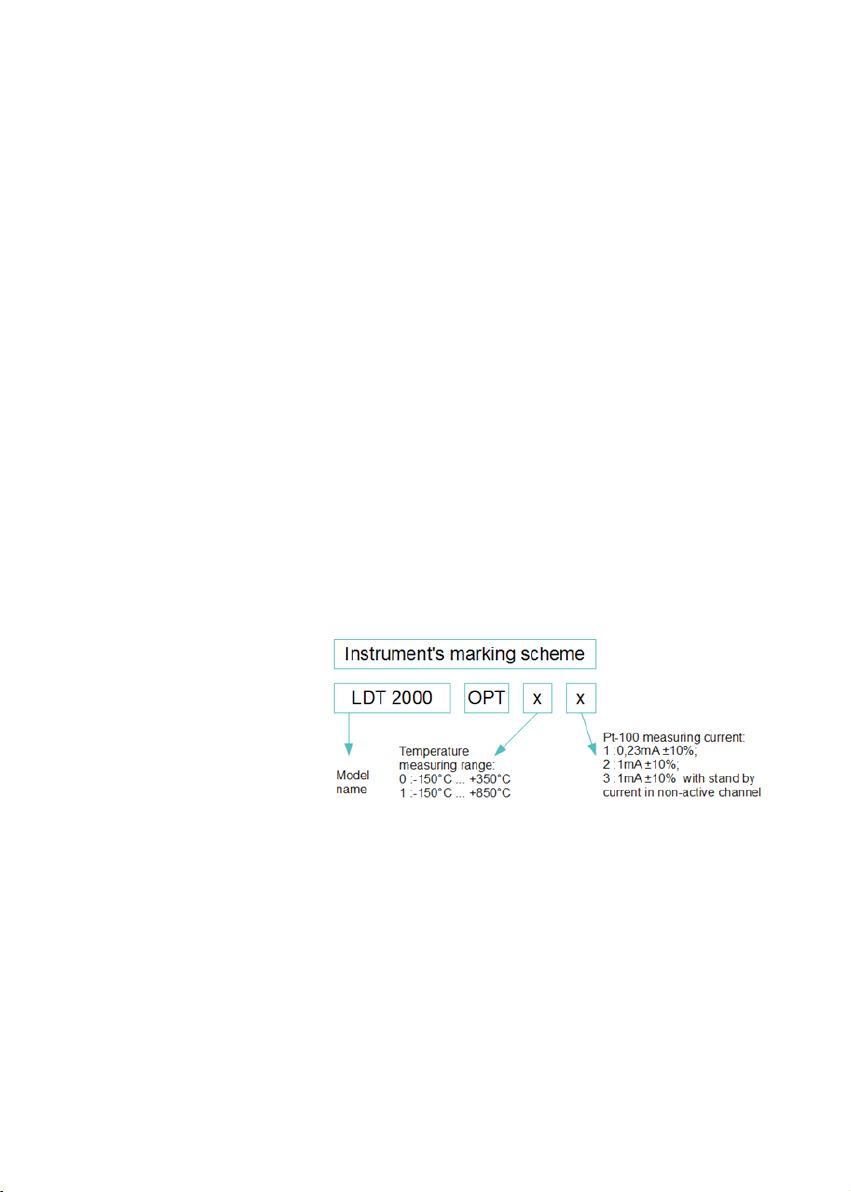

-150°C...+350°C(0…230,0000Ω)-OPT0x,0x,0x

-150°C...+850°C(0…450,0000Ω)-OPT1x,1x,1x

0,001°C(1mK),noise≤±1mK-OPT01,02,03

0,001°C(1mK),noise≤±3mK-OPT11,12,13

±0,007°C in the range 0°C … 100°C ; ±0,00014*(T-

50°C) beyond (with NIST-traceable calibrated probe

-on demand)

±0,020°C in the range 0°C … 100°C ; ±0,0004*(T-50-

°C) beyond (with probe calibrated by Leyro Instru-

ments)

±0,080°C in the range; ±0,0016*(T-50°C) beyond

(with uncalibrated probe)