INST.No.INE-378-P9CE

- C4 -

CONTENTS

1. Introduction.................................................... 1

1.1 General..................................................... 1

2. Model ............................................................ 2

2.1 Model........................................................ 2

2.2 Standard temperature range ..................... 3

2.3 System configuration................................. 3

3. Names and functions of component parts...... 4

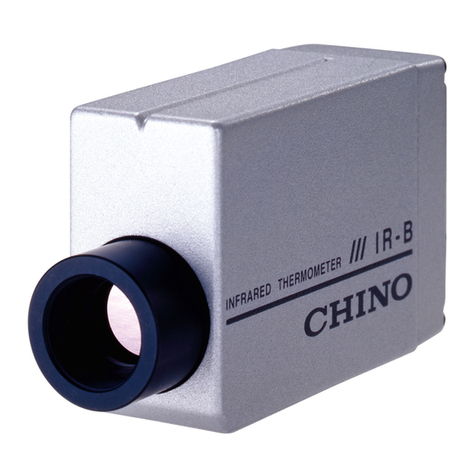

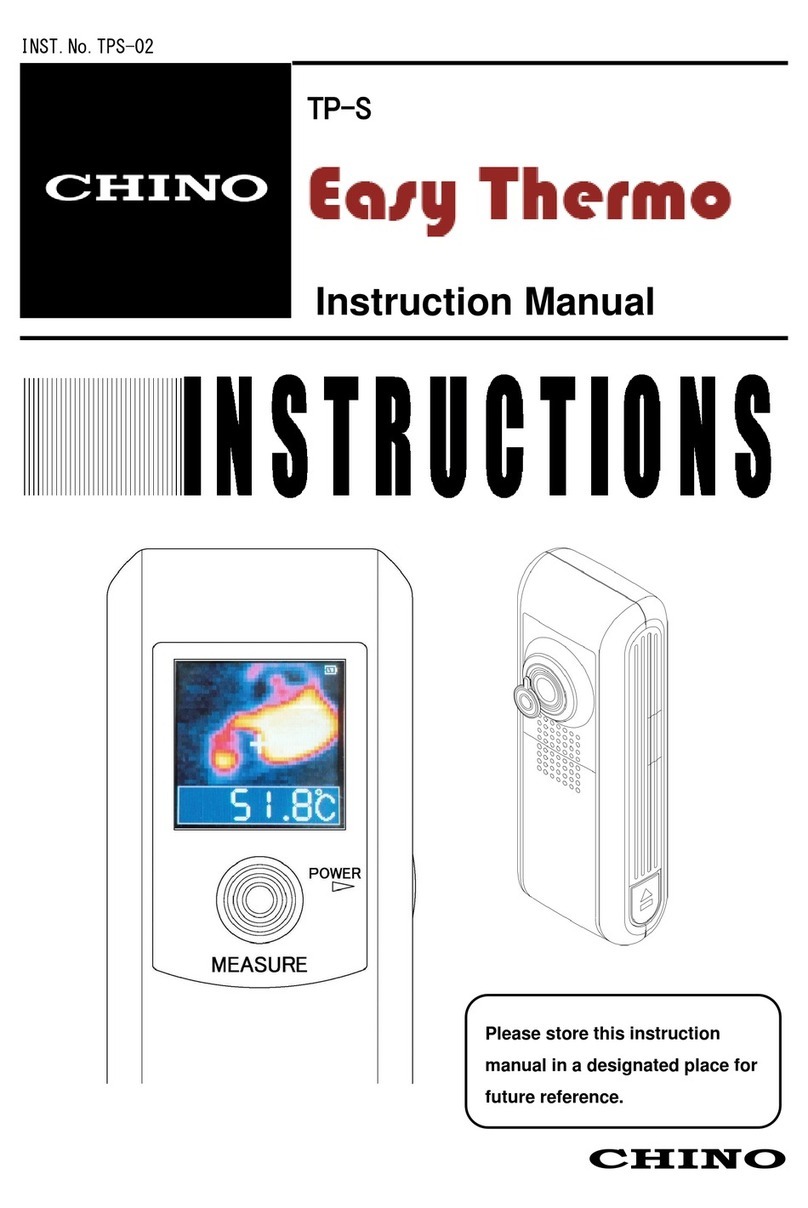

3.1 Thermometer............................................ 4

3.1.1 Thermometer view.................................... 4

3.1.2 Function key and digital display................ 5

3.1.3 Functions keys*1...................................... 5

3.1.4 Markers .................................................... 5

3.2 Fiber optics assembly ............................... 6

3.2.1 General-purpose type lens assembly........ 6

3.2.2 Lens assembly with air purge case........... 6

3.3 Fiber optics............................................... 7

4. Installation..................................................... 8

4.1 Installation of thermometer........................ 8

4.1.1 Using DIN rail ........................................... 8

4.1.2 Using mounting plate................................ 8

4.1.3 Installation/removal................................... 9

4.1.3-1 Installation............................................. 9

4.1.3-2 Removal................................................ 9

4.2 Installation of lens assembly ................... 10

4.2.1 General-purpose type lens assembly...... 10

4.2.2 Lens assembly with air purge case......... 10

4.2.3 Spot size and measuring distance

(General-purpose type lens assembly,

Lens assembly with air purge case).....11

4.3 Cautions on installation

/maintenance of fiber optics...... 12

4.4 Confirmation of view field........................... 12

5. Connections and wirings.............................. 13

5.1 Connections and wirings......................... 13

5.1.1 Connections of

fiber optics assembly to thermometer..... 13

5.1.2 Wirings to power terminals...................... 14

5.1.3 Wirings to ground terminals.................... 14

5.1.4 Wirings to receiving instruments............. 14

6. Operation .................................................... 15

6.1 Digital display.......................................... 15

6.2 Parameter programming

/selection (Operating mode)........ 15

6.3 Parameter programming

/selection (Engineering mode) .... 16

6.4 Operating Mode ...................................... 17

6.4.1 Emissivity programming.......................... 17

6.4.2 Automatic emissivity calculation.............. 17

6.4.2-1 Automatic emissivity calculation(Internal )

:Input of reference temperature...... 17

6.4.2-2 Automatic emissivity calculation

(External : IR-FA5 only)

: Selection of external programming.... 18

6.4.3 Signal modulation mode selection........... 18

6.4.4 Modulation degree programming ............ 19

6.4.4-1 Modulation time

constant programming ....... 19

6.4.4-2 Damping degree selection................... 19

6.4.5Alarm programming ................................ 20

6.4.5-1 Alarm type selection............................. 20

6.4.5-2 Alarm set-point..................................... 20

6.5 Engineering mode................................... 21

6.5.1 Analog output scaling programming........ 21

6.5.1-1 Analog output minimum value

programming…"OutL" ....... 21

6.5.1-2 Analog output minimum value

programming…"OutH"....... 21

6.5.2 Analog dummy output programming ....... 22

6.5.3 Hold functions

(Hold disable, sample hold, peak hold)

selection ........ 23

6.5.3-1 Hold function type selection................. 23

6.5.3-2 Peak hold reset type selection............. 24

6.5.3-3 Peak hold reset time programming...... 25

6.5.4 Measurement unit selection.................... 25

6.5.5 Contact output item selection.................. 26

6.5.6 Automatic emissivity calculation

type selection.......... 27

6.5.7 Zero/span adjustments ........................... 28

6.5.7-1 Zero / span adjustments

executive choice.............. 28

6.5.7-2 “Zero” side adjustment

…Adjustment by furnace temperature

at zero side...... 28

6.5.7-3 “Span” side adjustment

…Adjustment by furnace temperature

at span side ... 29