INTRODUCTION |5

Introduction

Due to our policy of continuous product innovation, some specications may change without notication.

© LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

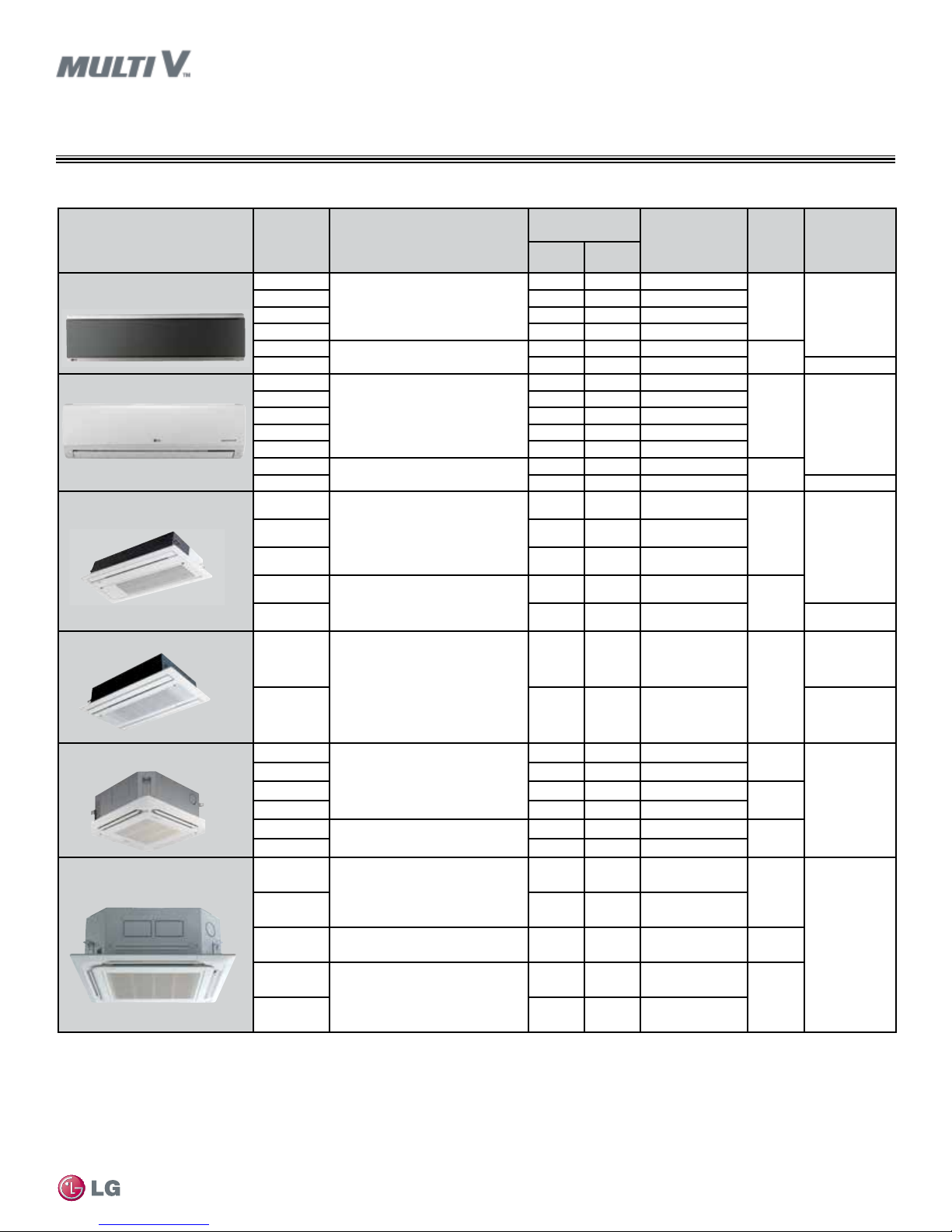

Unit/Type1ARNU*****2

Dimensions

(W x D x H)

(inches)

Nominal Capacity

Btu/h Air Flow Rate

(CFM)

(H/M/L4)

Weight

(lbs.)

Pipe

Connections

(inches, O.D.)

(Liquid, Vapor)

Cooling3Heating3

Wall Mounted–ART COOLTM

Mirror

073 SER2

36-1/16 x 6-1/2 x 11-1/8

7,500 8,500 247/212/141

25 1/4, 1/2

093 SER2 9,600 10,900 282/247/177

123 SER2 12,300 13,600 353/283/212

153 SER2 15,400 17,100 371/283/212

183 S8R2 43-9/16 x 7-7/8 x 11-13/16 19,100 21,500 508/459/388 34

243 S8R2 24,200 27,300 632/508/424 3/8, 5/8

Wall Mounted–Standard 053 SBL4

35-1/4 x 8-15/16 x 11-7/16

5,500 6,100 1,120/1,080/1,050

22 1/4, 1/2

073 SBL4 7,500 8,500 1,190/1,120/1,050

093 SBL4 9,600 10,900 1,260/1,190/1,050

123 SBL4 12,300 13,600 1,420/1,260/1,120

153 SBL4 15,400 17,100 1,550/1,350/1,190

183 SCL4 40-5/16 x 9-7/8 x 12-13/16 19,100 21,500 1,120/1,050/980 31

243 SCL4 24,200 27,300 1,280/1,140/1,000 3/8, 5/8

Ceiling Cassette–One Way 073 TUC4

Body: 33-7/8 x 17-3/4 x 6-11/16

Panel: 43-5/16 x 19-3/4 x 1-3/8

7,500 8,500 290/258/226

Body: 33

Panel: 10 1/4, 1/2

093 TUC4 9,600 10,900 325/304/290

123 TUC4 12,300 13,600 353/325/290

183 TTC4 Body: 46-1/2 x 17-3/4 x 6-7/8

Panel: 55-15/16 x 19-3/4 x 1-3/8

19,100 21,500 470/427/385 Body: 42

Panel: 13

243 TTC4 24,200 24,200 515/470/406 3/8, 5/8

Ceiling Cassette–Two Way

183 TLC4

Body: 32-11/16 x 21-5/8 x 8-7/8

Panel: 41-5/16 x 25-3/16 x 1-5/8

19,100 21,500 459/424/353

Body: 49

Panel: 11

1/4, 1/2

243 TLC4 24,200 27,300 601/530/459 3/8, 5/8

Ceiling Cassette–Four Way

(2' x 2')

053 TRC4

Body: 22-7/16 x 22-7/16 x 8-7/16

Panel: 27-9/16 x 27-9/16 x 7/8

5,500 6,100 265/247/212 Body: 29

Panel: 7

1/4, 1/2

073 TRC4 7,500 8,500 265/247/212

093 TRC4 9,600 10,900 283/265/251 Body: 32

Panel: 7

123 TRC4 12,300 13,600 307/283/247

153 TQC4 Body: 22-7/16 x 22-7/16 x 10-3/32

Panel: 27-9/16 x 27-9/16 x 7/8

15,400 17,100 388/353/328 Body: 35

Panel: 7

183 TQC4 19,100 21,500 396/388/353

Ceiling Cassette–Four Way

(3' x 3') 243 TPC4 Body: 33-1/16 x 33-1/16 x 8

Panel: 37-3/8 x 37-3/8 x 1-7/16

24,200 27,300 600/530/459 Body: 48

Panel: 13

3/8, 5/8

283 TPC4 28,000 31,500 671/565/494

363 TNC4 Body: 33-1/16 x 33-1/16 x 9-5/8

Panel: 37-3/8 x 37-3/8 x 1-7/16 36,200 40,600 883/777/706 Body: 54

Panel: 13

423 TMC4 Body: 33-1/16 x 33-1/16 x 11-5/16

Panel: 37-3/8 x 37-3/8 x 1-7/16

42,000 43,800 1,059/918/812 Body: 59

Panel: 13

483 TMC4 48,100 51,200 1,130/953/883

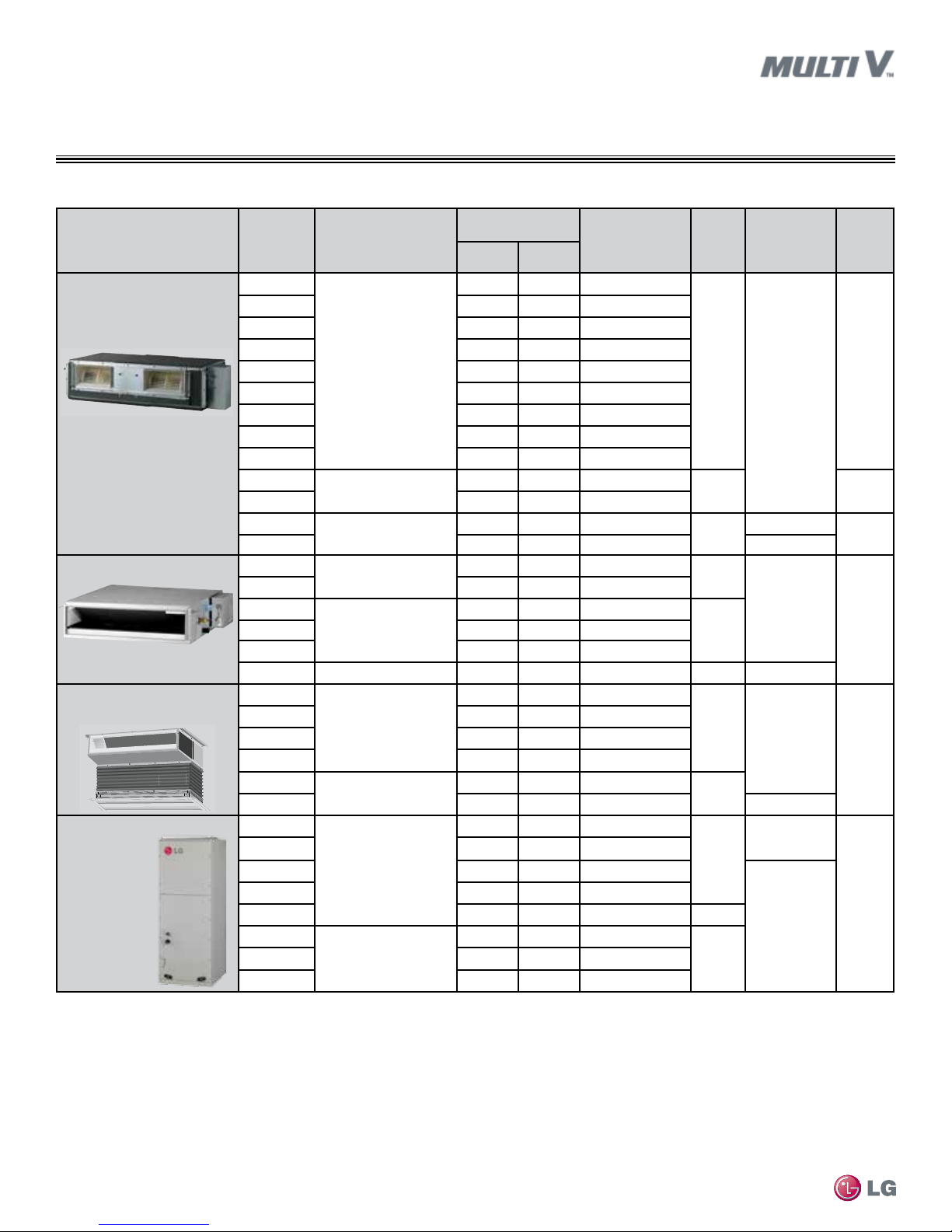

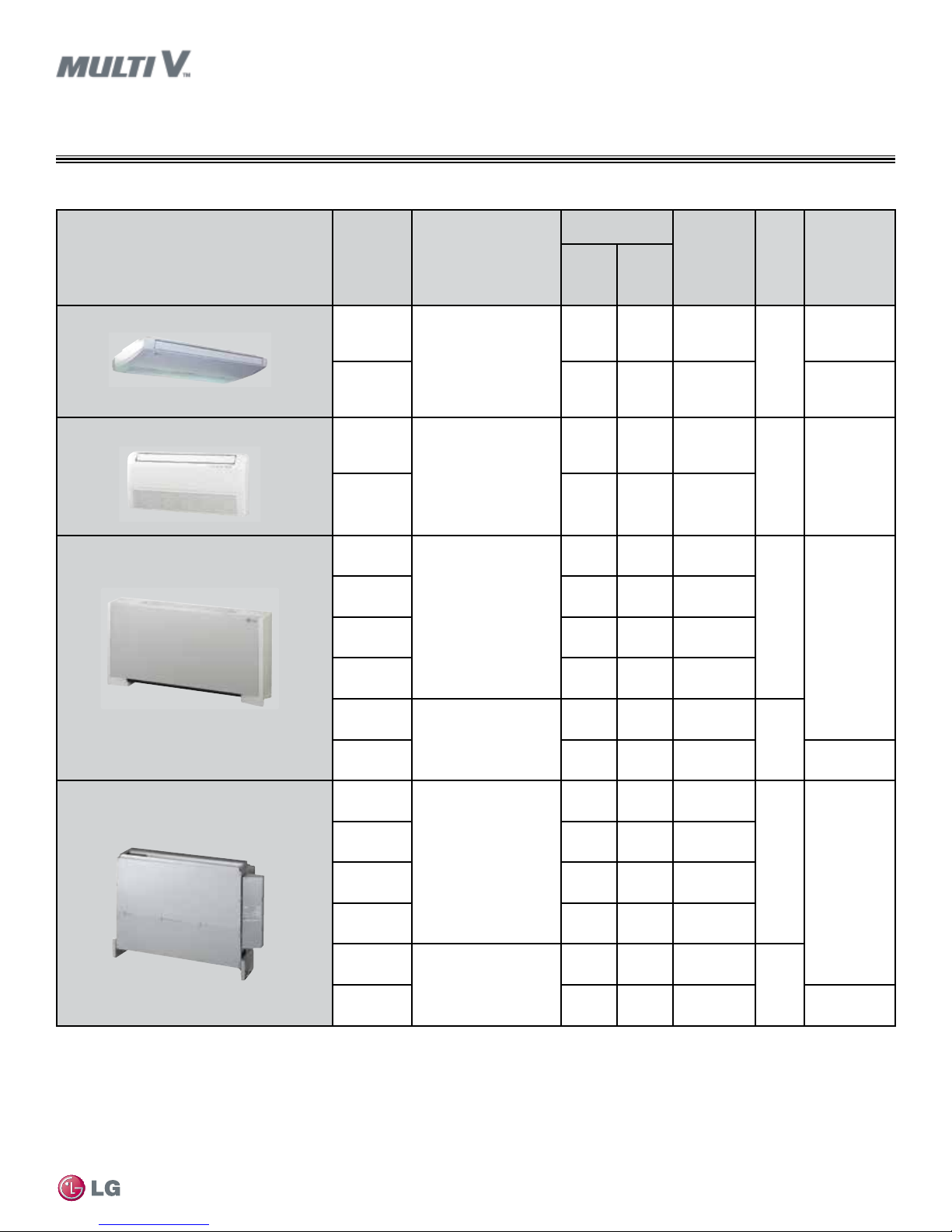

INDOOR UNIT OVERVIEW

Table 1: Wall-Mounted / Ceiling Cassette Indoor Units.

1All indoor units require 208–230V/60Hz/1Ph and an AWG18-2 communication cable.

2Model number shows nominal capacity and frame size designator.

3Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 60°

F wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

4H/M/L = High/Medium/Low

Wall-Mounted / Ceiling Cassette