Functions

•Room temperature sensor. (THERMISTOR)

•Maintains the room temperature in accordance with the Setting Temp.

•Indoor fan is delayed for 5 sec at the starting.

•Restarting is inhibited for approx. 3 minutes.

•High, Med, Low, CHAOS

•Intermittent operation of fan at low speed.

•The fan is switched to low(Cooling), med(Heating) speed.

•The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

•The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

•The louver can be set at the desired position or swing

up and down automatically.

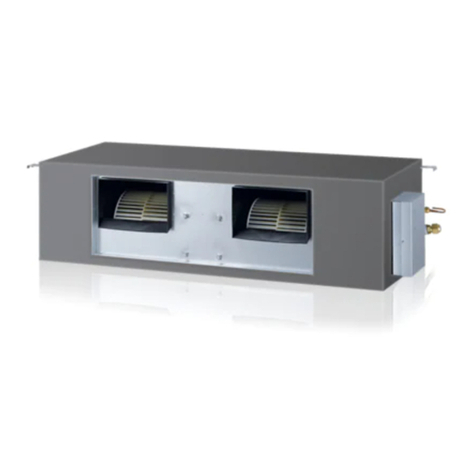

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

•Both the indoor and outdoor fan stops dur-

ing defrosting.

•The indoor fan stops until the

evaporator pipe temperature will be reached

at 28°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

-5-

Defrost(Deice) control (Heating)

Hot-start Control (Heating)

Signal Receptor

Receives the signals from the remote control.(Signal receiving sound: two short beeps or one long beep.)

Operation Indication Lamps

On/Off : Lights up during the system operation.

Sleep Mode : Lights up during Sleep Mode Auto operation.

Timer : Lights up during Timer operation.

Defrost Mode : Lights up during Defrost Mode or

Hot Start operation.(Heat pump model only)

Outdoor unit operation : Lights up during outdoor unit operation.

(Cooling model only)

PLASAM : Indicate operation of PLASMA purifier.

OUT

DOOR