2Room Air Conditioner

Air Conditioner Service Manual

TABLE OF CONTENTS

Preface ........................................................................3

Electronic Type ........................................................3

Mechanical Type......................................................3

Safety Precautions.....................................................4

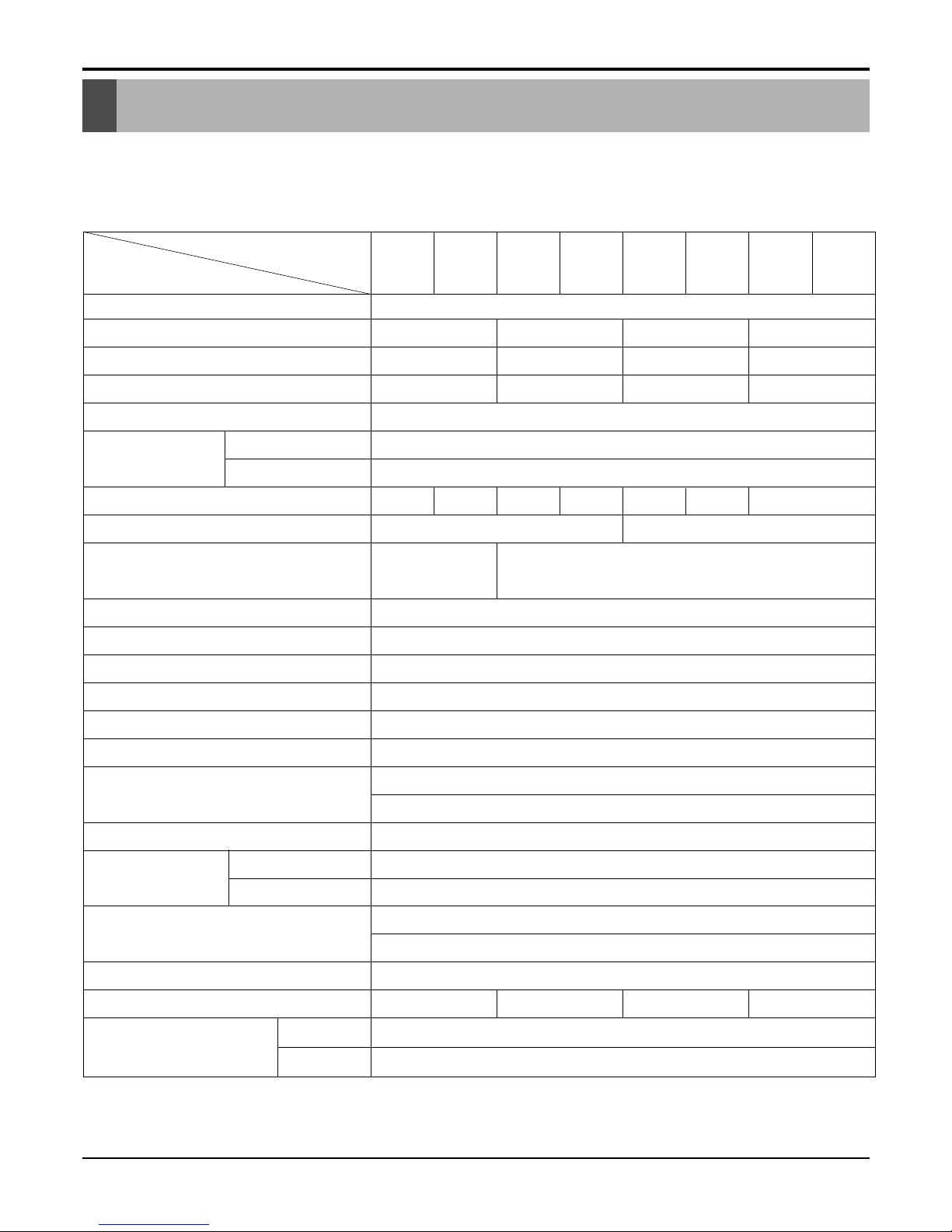

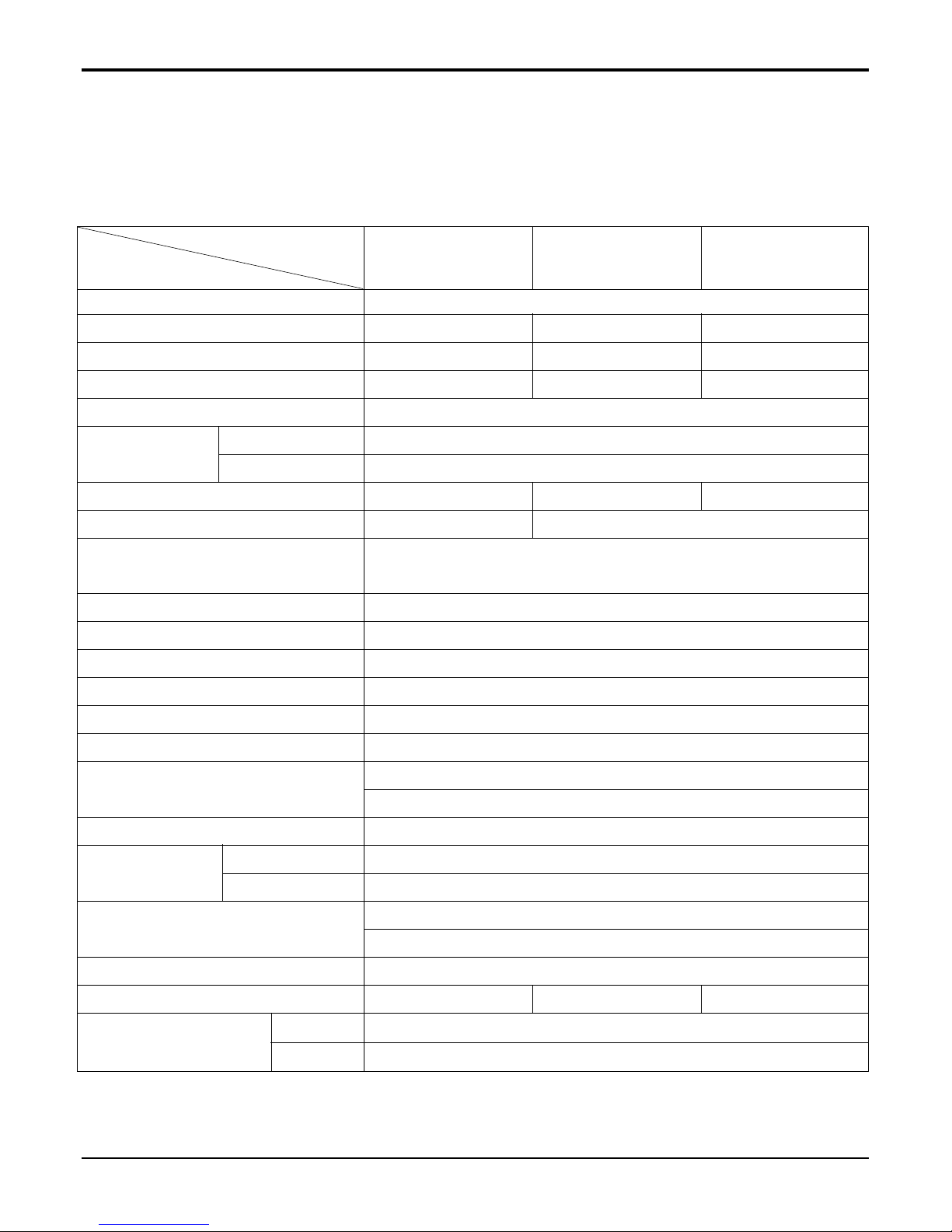

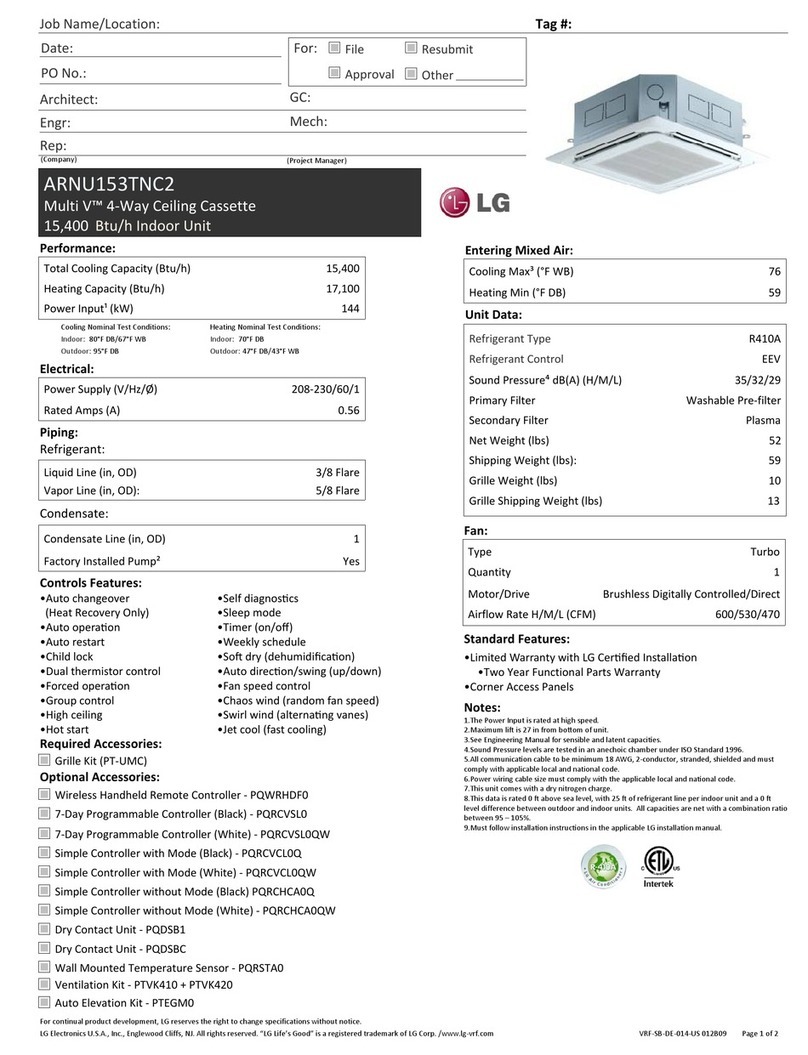

Product Specifications ..............................................6

Operation ....................................................................8

Features ..................................................................8

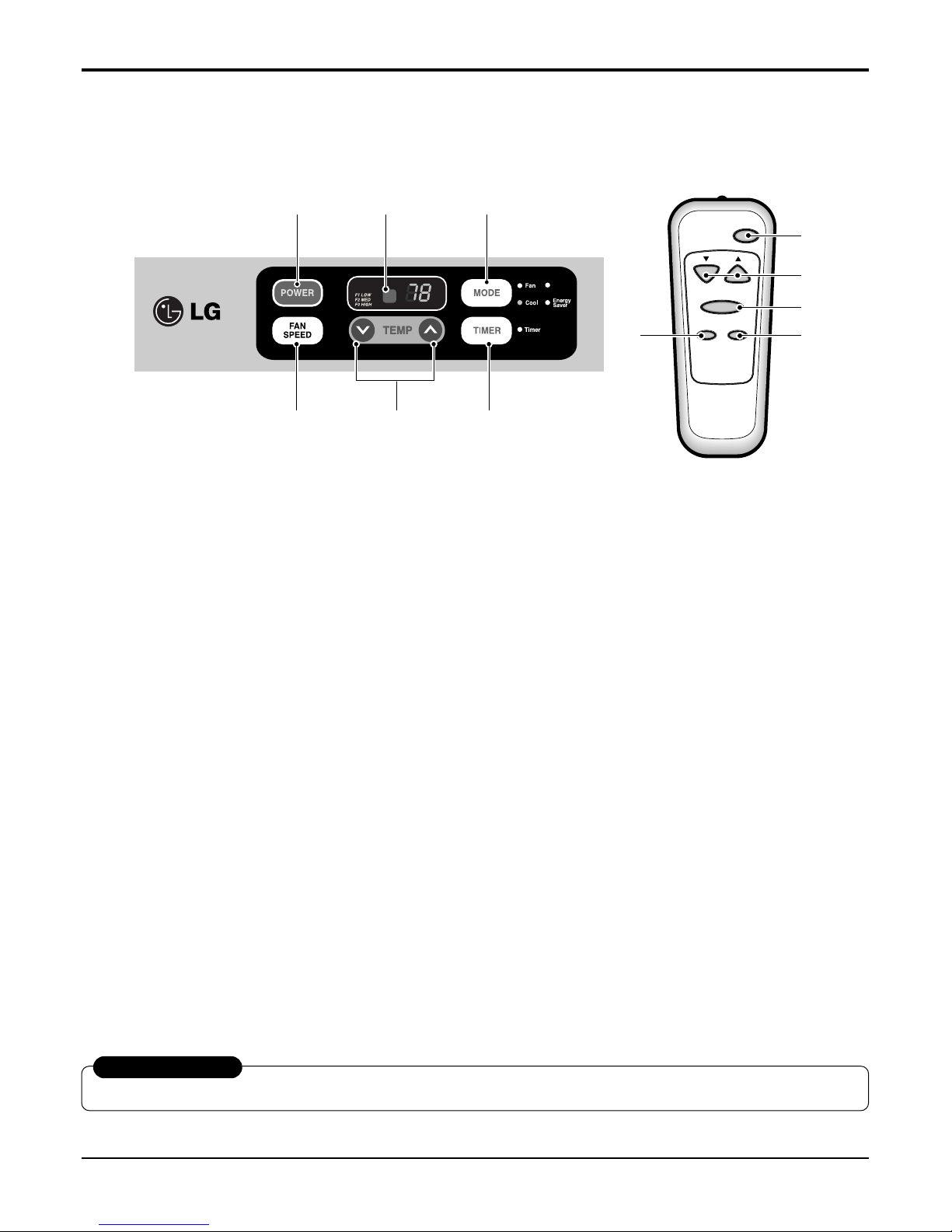

Control Locations ....................................................8

Mechanical type model .......................................8

Electronic type model..........................................9

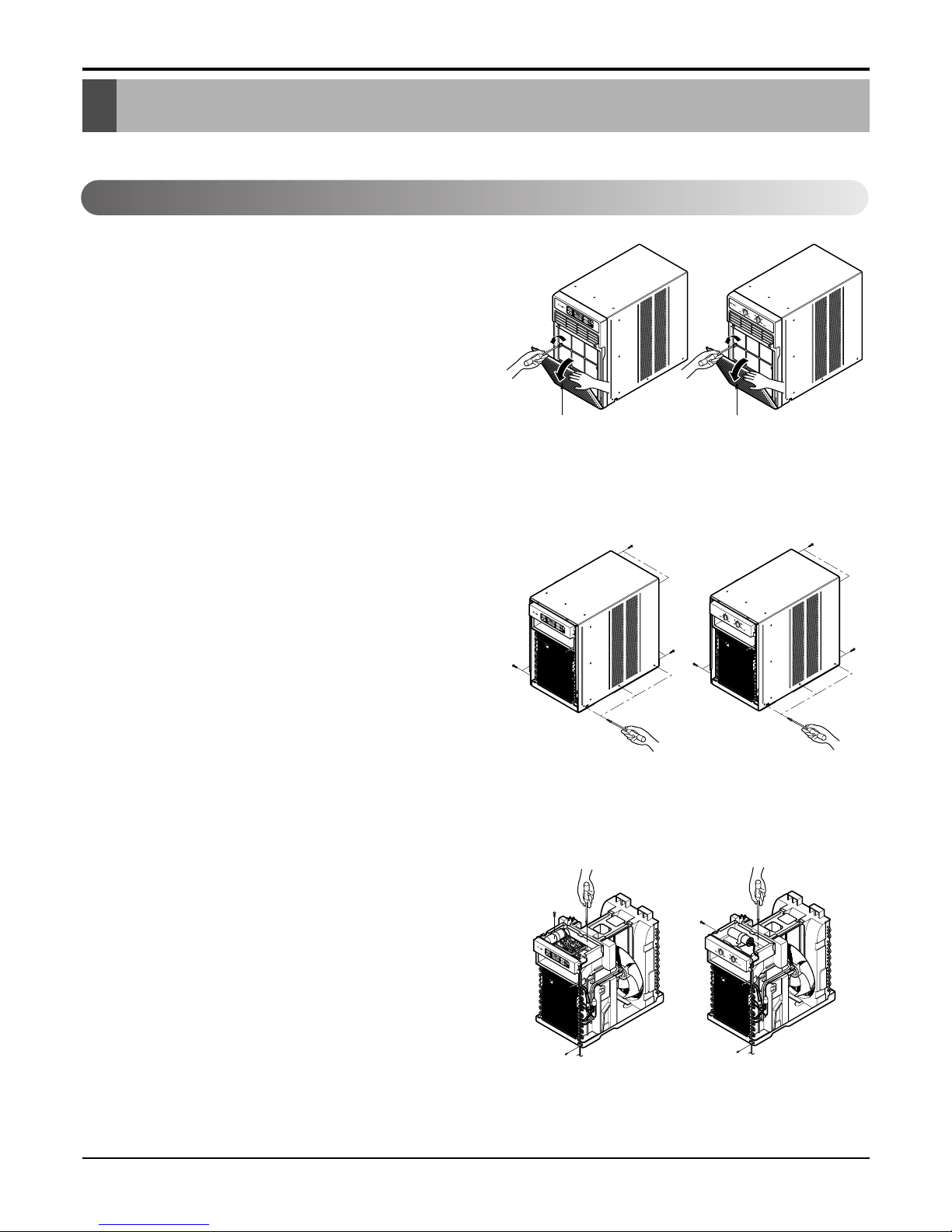

Disassembly Instructions........................................10

Mechanical Parts...................................................10

Front grille .........................................................10

Cabinet..............................................................10

Control box........................................................10

Air Handling Parts .................................................11

Air guide and turbo fan......................................11

Fan ....................................................................11

Shroud ..............................................................12

Electrical Parts ......................................................12

Overload protector ............................................12

Compressor ......................................................12

Capacitor...........................................................13

Power cord ........................................................13

Thermostat........................................................13

Rotary switch ....................................................13

Motor.................................................................14

Refrigerating Cycle................................................14

Condenser ........................................................14

Evaporator.........................................................14

Capillary tube....................................................15

Installation ................................................................17

How to Install the unit ............................................17

Checking installation..............................................17

How to drain ..........................................................17

Window Requirements ..........................................18

Installation Kits Contents.......................................18

Horizontal Sliding Window Installation...................19

Casement Window Installation ..............................20

Troubleshooting Guide ............................................21

Outside dimensions ..............................................21

Piping system ........................................................21

Troubleshooting Guide...........................................22

Room Air Conditioner Voltage Limits.....................29

Mechanical type model .....................................29

Electronic type model........................................29

Schematic Diagram.................................................33

Circuit Diagram......................................................33

Electronic Control Device ......................................38

Components Location

(For Main P.C.B ASM)............................................39

Components Location

(For Display P.C.B ASM)........................................39

Exploded View & Replacement Parts List .............40

![LG ATNH24GPLED[UT24 NPD] User manual LG ATNH24GPLED[UT24 NPD] User manual](/data/manuals/28/2/282om/sources/lg-atnh24gpled-ut24-npd-air-conditioner-manual.jpg)