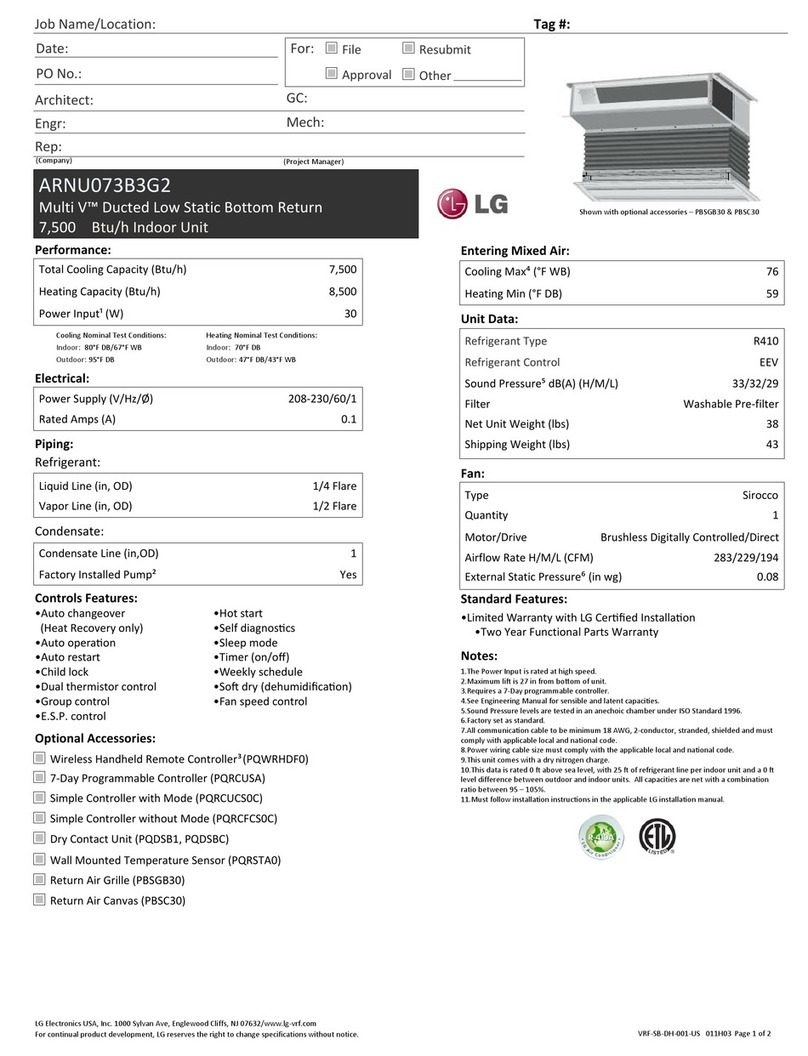

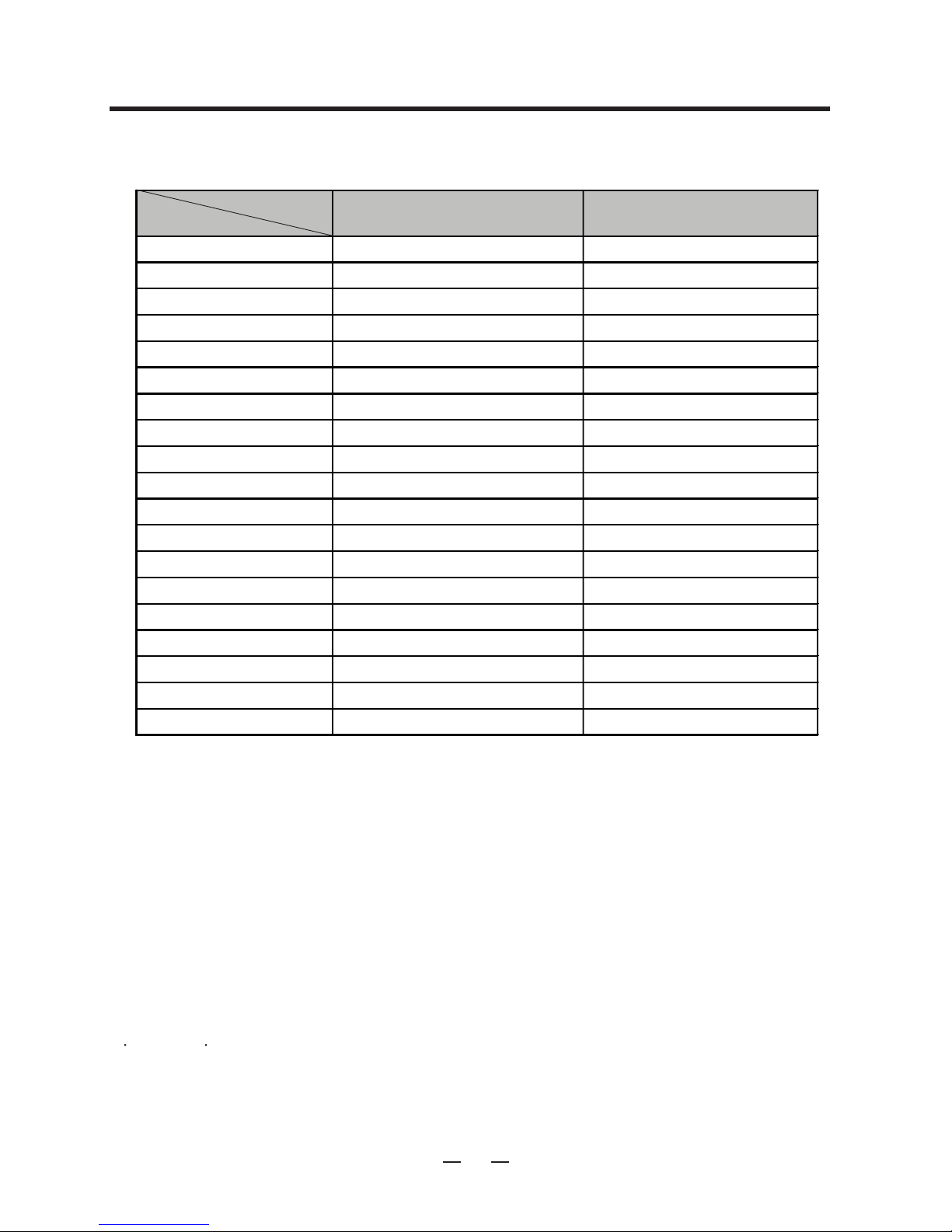

Note : 1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27.0 (80.6°F ) DB/19.0 (66.2°F) WB

- Outdoor Temperature 35 (95°F) DB/24 (75.2°F) WB

Piping Length - Interconnecting Piping Length 7.5m

'- Level Difference of Zero

2. Nominal CFM : Fan operation mode with clean filter, dry coil.

3. The specification may be subject to change without prior notice for purpose of improvement.

Conversion Formula

kcal/h = kW x 860

Btu/h = kW x 3412

cfm = m 3/min x 35.3

(RT) 20

TN-C240BT00

kW 53.54 70.41

Btu/h 182 700 240 239

kW 52.75 67.41

Btu/h 180 000 230 000

kW - -

Btu/h - -

Ø / V / Hz 3/220ѝѝ

Cooling A 76

Heating A - -

Cooling W 22 000 2

Heating W - -

CFM 5 300 7 500

Btu/h.W 8.18 9.02

Btu/h.W - -

W/W - -

bell+3 67 6

bell+3

High efficiency High efficiency

mm(inch) 9.52(3/8) 9.52(3/8)

3R / 30C / 17FPI 3R / 30C / 17FPI

mm(inch) 1500(59 17/32) 1500(59 17/32)

༇

1.14(12.33) 1.14(12.33)

Centrifugal Blower Centrifugal Blower

mm(inch) 393(15 15/32) 393(15 15/32)

mm(inch) 557(21 15/16) 557(21 15/16)

WEITELI WEITELI

Belt/1 Belt/1

11

Hp 4.0/6.0 4.0/6.0

1 0/ 1 0 1 0/ 1 0

11

SCROLL * 4 SCROLL * 4

Btu/h 49 500 62 000

W 4625 5538

SUNISO 4GSI SUNISO 4GSI

cc 1800 1950

High efficiency High efficiency

mm(inch) 9.52(3/8) 9.52(3/8)

3R / 40C / 14FPI*2 3R / 40C / 14FPI*2

mm(inch) - -

༇

0.50 0.50

Propeller * 2 Propeller * 2

inch - -

--

Direct Direct

CFM 8200 8200

Hp 2EA / 1.5 2EA / 1.5

90 90

mm(inch) 15.88(5/8) 15.88(5/8)

mm(inch) 28(9/8) 28(9/8)

mm(inch) 15.88(5/8) 15.88(5/8)

mm(inch) 28(9/8) 28(9/8)

m(inch) 7.5(295 9/32) 7.5(295 9/32)

˜

/h 17 17

1 1/4 1 1/4

kg 7.5*2 7.6*2

lbs - -

Type R22 R22

Capillary Tube Capillary Tube

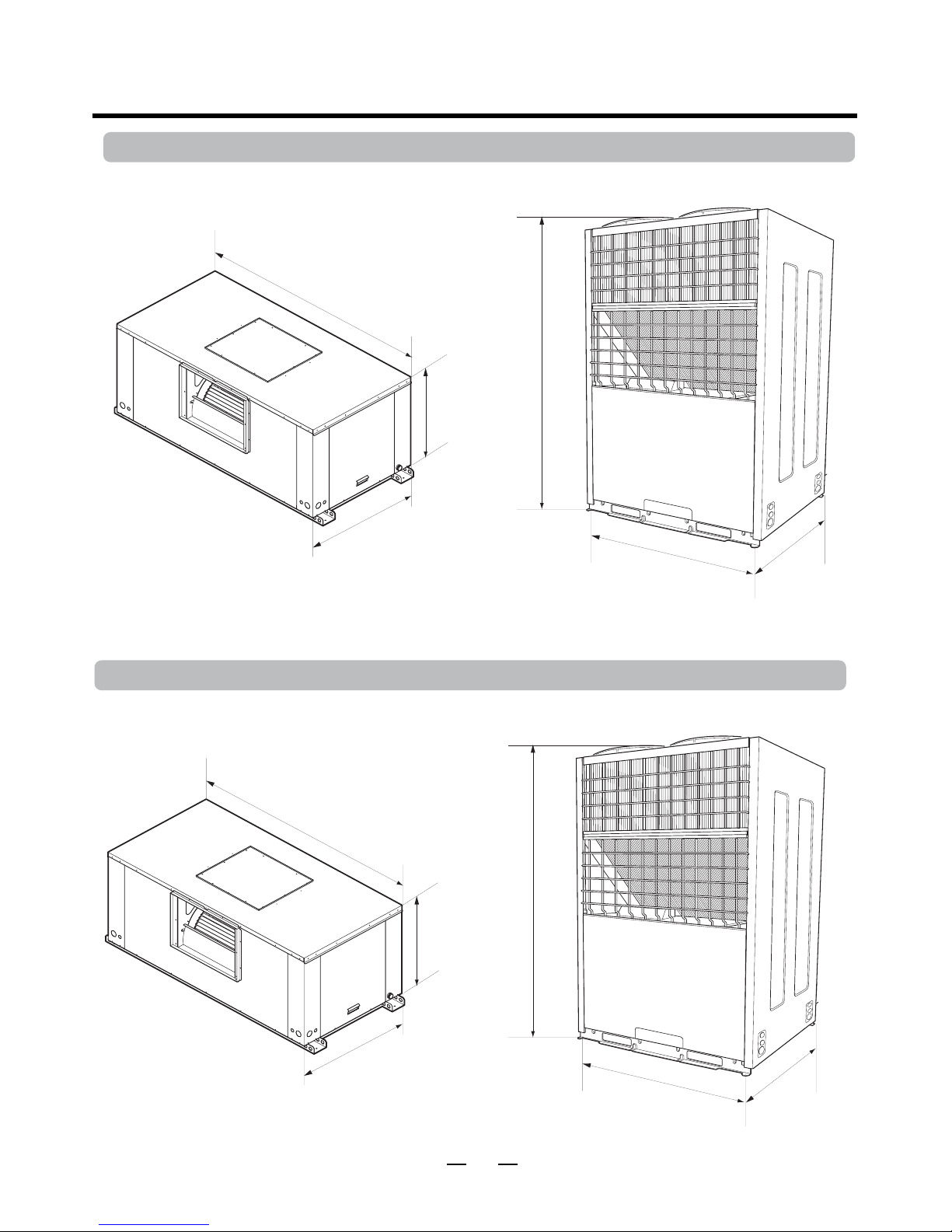

mm 1800*890*1000 1800*890*1000

inch 70 7/8* 35 3/8 *39 3/8 70 7/8* 35 3/8 *39 3/8

mm 1560*1100*880 1760*1100*970

inch 61 7/16* 43 5/16 * 34 5/8 69 1/4* 43 5/16 * 38 3/16

kg(lbs) 250˄550˅250˄550˅

kg(lbs) 340(748) 340(748)

--

inch - -

Outdoor Unit or S/Package

Dimensions

Indoor Unit (W * H * D)

Refrigerant Refrigerant Charge

Refrigerant Control

Service Valve Liquid

Gas

Outdoor Motor

No. Motor / Motor Output(Hp)

Air Circulation

Drive Type

Maker

Outdoor Fan Type * No. Used

Diameter

Length

Face Area

Tube Size(O.D)

Rows / Column / FPI

No. of Outdoor Units

Motor Output(Standard / Oversized)

No. Motors

Drive Type / Motor Step

Width

Indoor Fan

Type * No. Used

Length

Tube Size(O.D)

Sound Rating˄outdoor˅

Sound Rating˄indoor˅

SEER

Performance

Air Circulation(Nominal)

COP

EER

Power Input

M.C.A

(with Standard Motor)

TN-C180BT00

15

Outdoor Unit

(W * H * D)

Net Weight Indoor Unit

Fliter Size * No. Used

Filter Rack Thickness

Length(Standard)

Connecting Pipe

Motor RPM

Compressor

Motor Input

Oil Type

Oil Charge

Condenser

Drain Connection Size(inch)

Liquid

Gas

Dehumidification Rate

Type

Type * Quantity

Model

Maker

Capacity

Motor Type

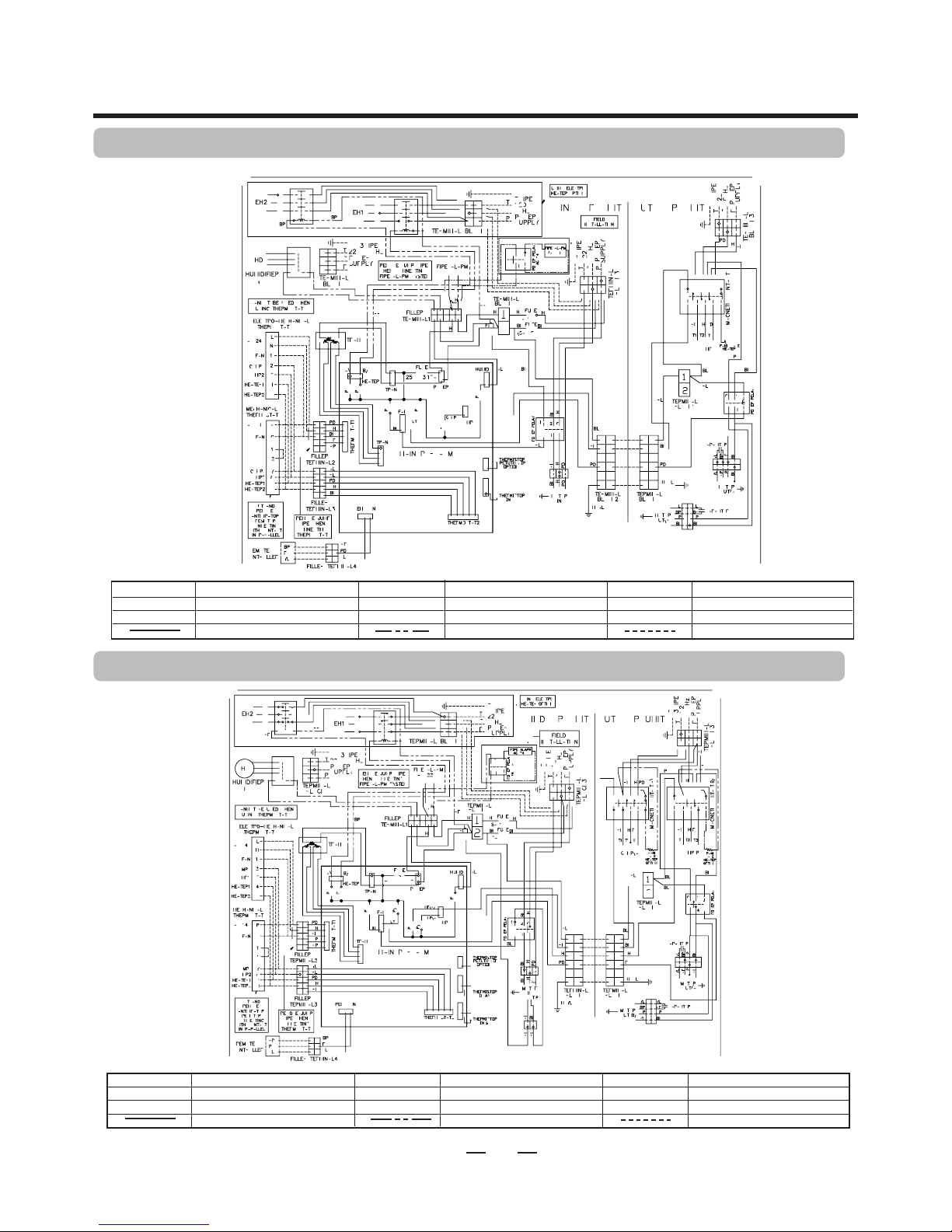

Electrical Data

Power Supply

Indoor Motor

Maker

Diameter

Evaporator

Type

Rows / Column / FPI

Face Area

Motor RPM(Standard / Oversized)

Nominal RT

Models

Gross Cooling Capacity

Net Cooling Capacity

Capacity

Net Heating Capacity

9

75 75

240/60 3/220 240/60

SR049RAC SR061RBA

LG LG

One Phase One Phase

140

5 500

72 73 72 73

77

General Data

6