5. Off Timer Function

This function is to set the time of stopping the unit operation.

The procedure is as the following.

1st: Press the timer set button on the Remocon.

2nd:

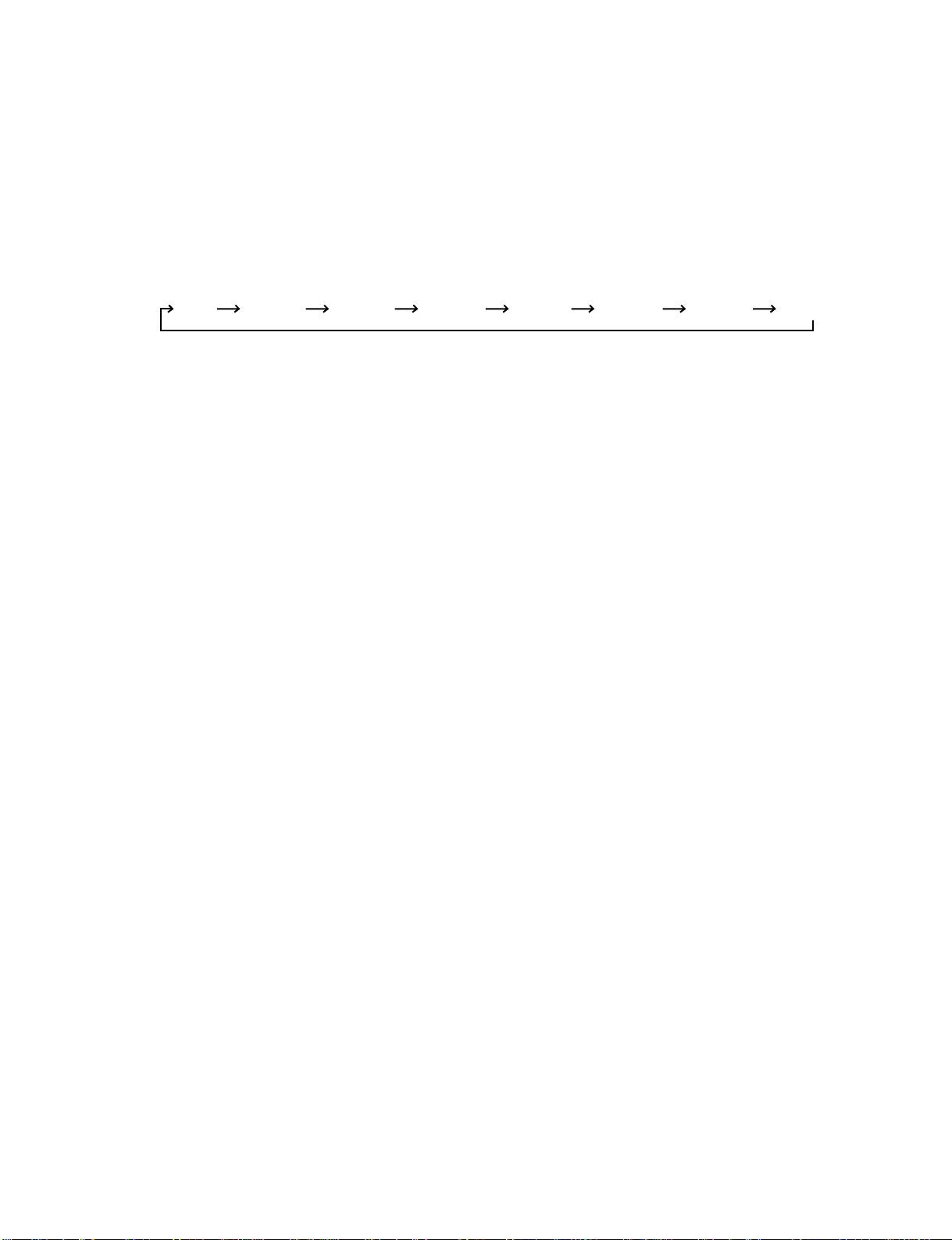

The buzzer sounds and then the display window shows the Off-Time to be set as 1:00→... →7:00 →0:00.

- The Off-Time is shifted as the following by each press.

- If you select '0:00', the Off-Timer function will be cancelled.

- During Off-Timer Operation, if you repress the timer set button, the rest time will be displayed.

6. Alarm mode display / only displayed while operating.

CCHH00

: The sensor for sensing room temperature is open or short.

CCHH11

: The sensor for sensing piping temperature of evaporator is open or short.

7. Function for test operation.

This function shall be operated while the set not operating and start while set temperature set button(▼) down

and start/stop buttons pressing continuously for 3 seconds.

If you press start/stop button continuously for 3 seconds while set temp down button pressing once more test

operation and the set shall be stopped.

After test operation operating and 18 minutes, test operation and the set shall be stopped.

If you press start/stop button while test operation operating, test operation shall be stopped and the set shall

start.

When test operation operating, the display of

8888::8888

shall be shifted to tESt

Regardless of outside temperature, the set operates when test operation.

8. Function of changing set temperature when re-operation after stop.

Cooling operation is set to the previous set temperature when re-operation with start/stop button.

1.Operation mode.

Cooling →Cooling mode

2. Setting the set temperature when cooling operation.

Room temperature > Set temperature: to be set to the previous set temperature.

Room temperature ≤Set temperature

a) Room temperature ≥26°C: to be set to 24°C

b) 22°C ≤Room temperature ≤25°C: to be set to 21°C

c) Room temperature ≤21°C:to be set to -1°C less than room temperature.

9. Auto Restart

In case the power comes on again a power failure, Auto Restarting Operation is the function to operate proce-

dures automatically to the previous operating conditions.

–10 –