- 2 -

Copyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes LGE Internal Use Only

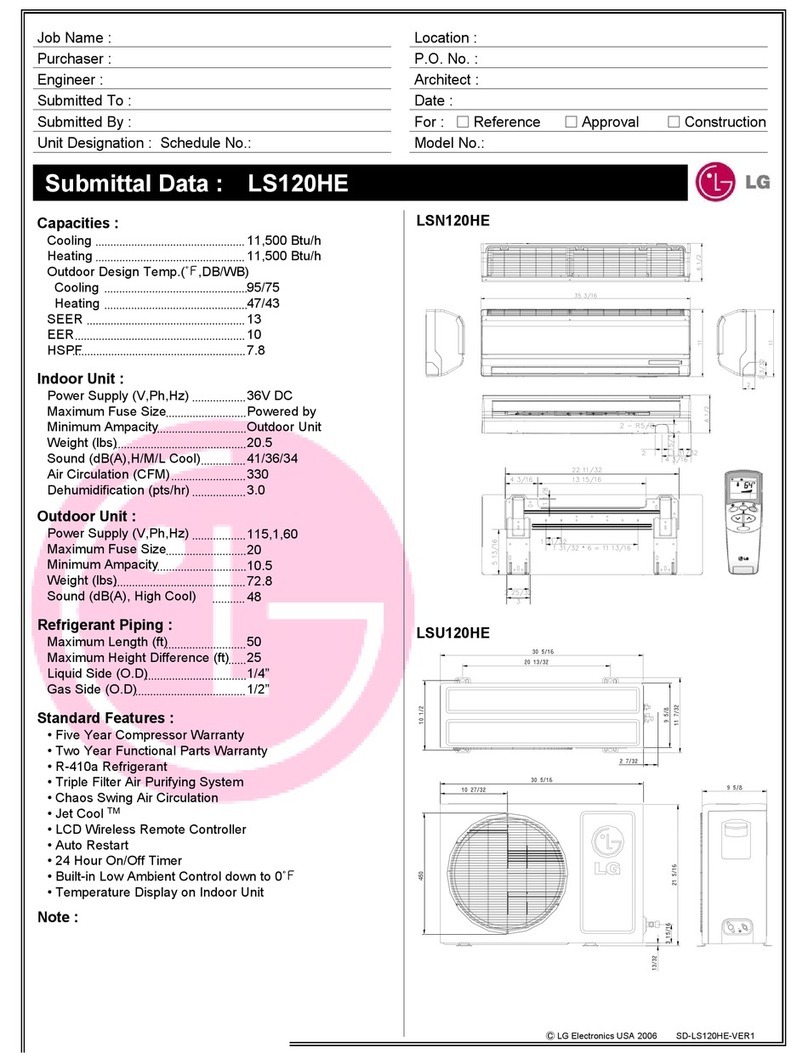

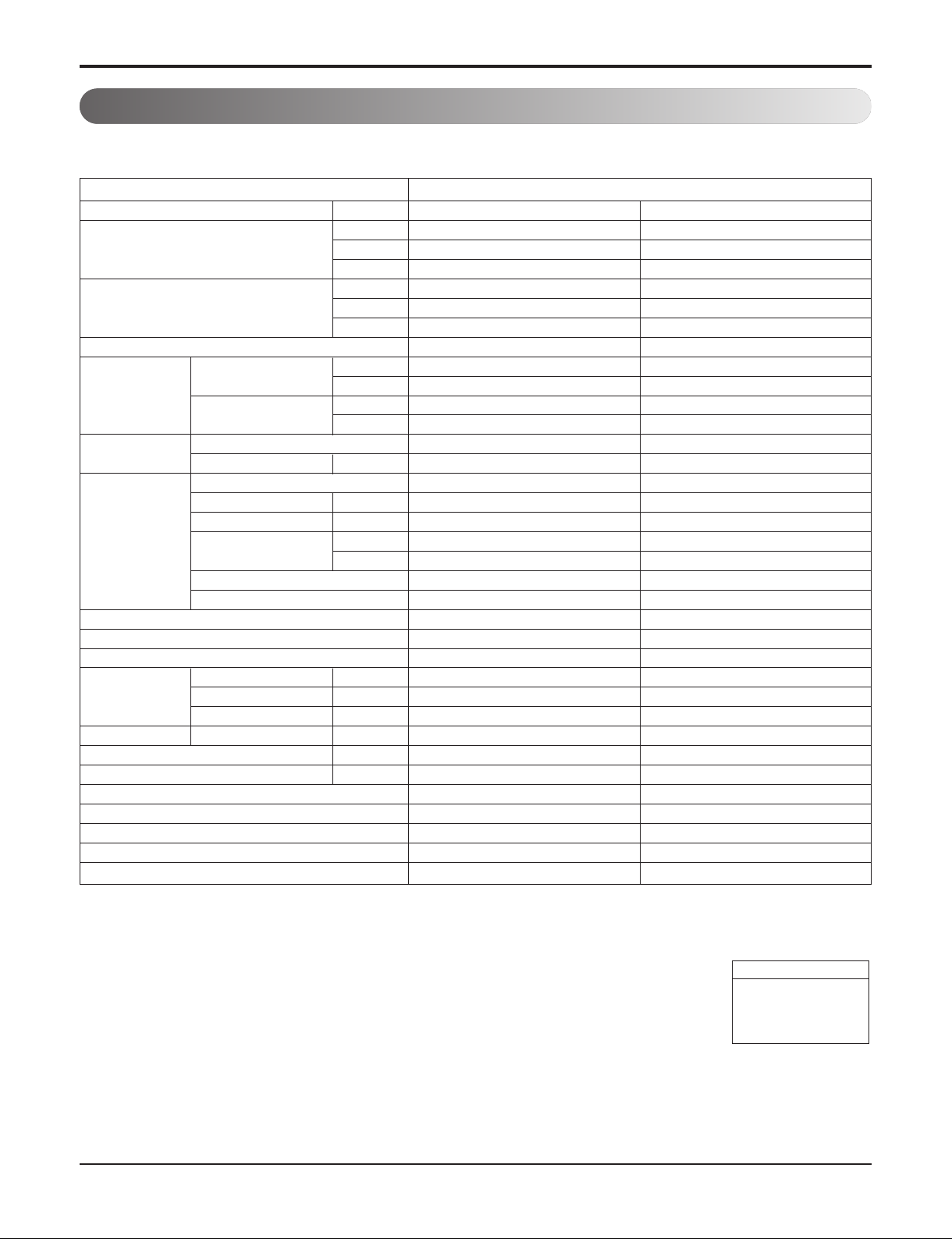

1. Specification

Type

Model Unit

kW

Cooling Capacity kcal/h

Btu/h

kW

Heating Capacity kcal/h

Btu/h

Casing

Body mm

Dimensions (WxDxH)

inch

Front Panel mm

inch

Coil

Rows x Columns x FPI

Face Area m2(ft2)

Type

Motor Output x Number

W

Running Current A

Fan Air Flow Rate(H/M/L) CMM

cfm

Drive

Motor type

Temperature Control

Sound Absorbing Thermal Insulation Material

Safety Device

Liquid Side mm(inch)

Pipe Connections

Gas Side mm(inch)

Drain Pipe(Internal Dia.)

mm(inch)

Net Weight Body kg(lbs)

Noise Level

(Sound Press, 1.5m, H/M/L)

dB(A)

Power Supply Ø, V, Hz

Refrigerant Control

Power cable

Transmission cable

Panel Color

Panel Name(Acc'y)

ARNU09GTL*4

2.8

2,400

9,600

3.2

2,800

10,900

Galvanized Steel Plate

830x550x225

32-11/16 x 21-21/32 x 8-27/32

1,050x640x28.5

41-11/32 x 25-3/16 x 1-3/32

2x11x20

0.13(1.4)

Cross Flow Fan

20x2

0.18x2

9 / 8 / 7

318 / 283 / 247

Direct

BLDC

Microprocessor, Thermostat for cooling and heating

Foamed polystrene

Fuse

Ø6.35(1/4)

Ø12.7(1/2)

25.0(1)

20.6(45.4)

36 / 34 / 32

1,220-240,50

EEV

CV 1.5 x 3C**

CVV-SB 1.0 ~ 1.5 × 2C

Morning fog

PT-HL*

ARNU12GTL*4

3.6

3,100

12,300

4.0

3,400

13,600

Galvanized Steel Plate

830x550x225

32-11/16 x 21-21/32 x 8-27/32

1,050x640x28.5

41-11/32 x 25-3/16 x 1-3/32

2x11x20

0.13(1.4)

Cross Flow Fan

20x2

0.18x2

10 / 9 / 8

353 / 318 / 283

Direct

BLDC

Microprocessor, Thermostat for cooling and heating

Foamed polystrene

Fuse

Ø6.35(1/4)

Ø12.7(1/2)

25.0(1)

20.6(45.4)

38 / 36 / 32

1,220-240,50

EEV

CV 1.5 x 3C**

CVV-SB 1.0 ~ 1.5 × 2C

Morning fog

PT-HL*

Notes:-

1. Capacities are based on the following conditions:

Cooling • Indoor temp. 27°C[80.6°F]DB/ 19°C[66.2°F]WB

• Outdoor temp. 35°C[95°F]DB/ 24°C[75.2°F]WB

• Interconnecting Piping Length 7.5m(24.6ft)

• Level Difference of Zero

Heating • Indoor temp. 20°C[68°F]DB/ 15°C[59°F]WB

• Outdoor temp. 7°C[44.6°F]DB/ 6°C[42.8°F]WB

• Interconnecting Piping Length 7.5m(24.6ft)

• Level Difference of Zero

2. Capacities are Net Capacities

3. Due to our policy of innovation some specifications may be changed without prior notification

4. To be added for more available Models

5. EEV : Electronic Expansion Valve

* Model Name

A:Basic, C:Plasma

Conversion Formula

kcal/h= kW x 860

Btu/h = kW x 3412

cfm = m3/min x 35.3

l/s = CMM x 1000/60

2Way Ceiling Cassette

** : Wiring cable size must comply with the applicable local and national codes. And “Electric characteristics” chapter should be considered for

electrical work and design. Especially the power cable and circuit breaker should be selected in accordance with that