- 1 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes LGE Internal Use Only

Air Conditioner Service Manual

CONTENTS

Part 1 General Information ..........................................................................................................2

1. Safety Precautions........................................................................................................3

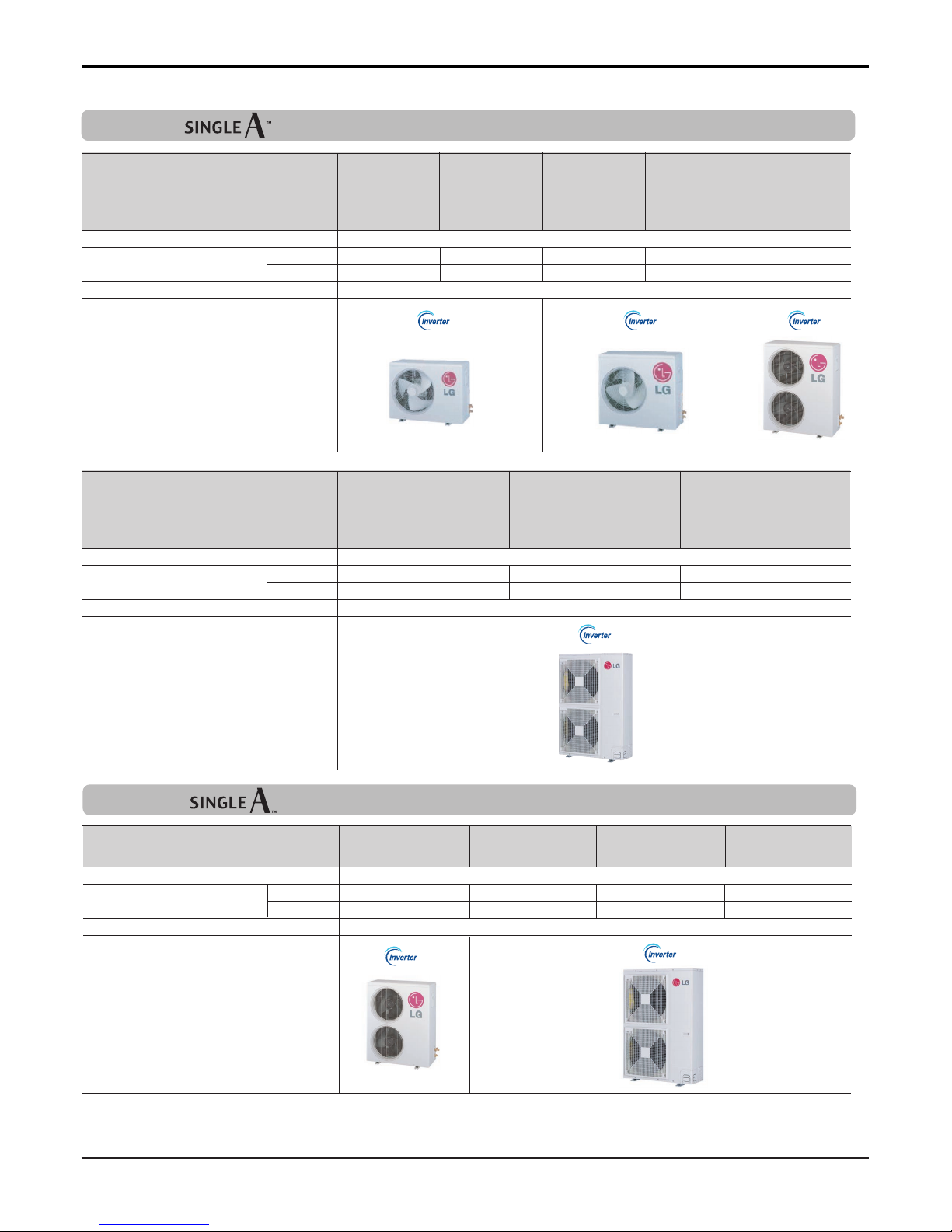

2. Model Line up................................................................................................................6

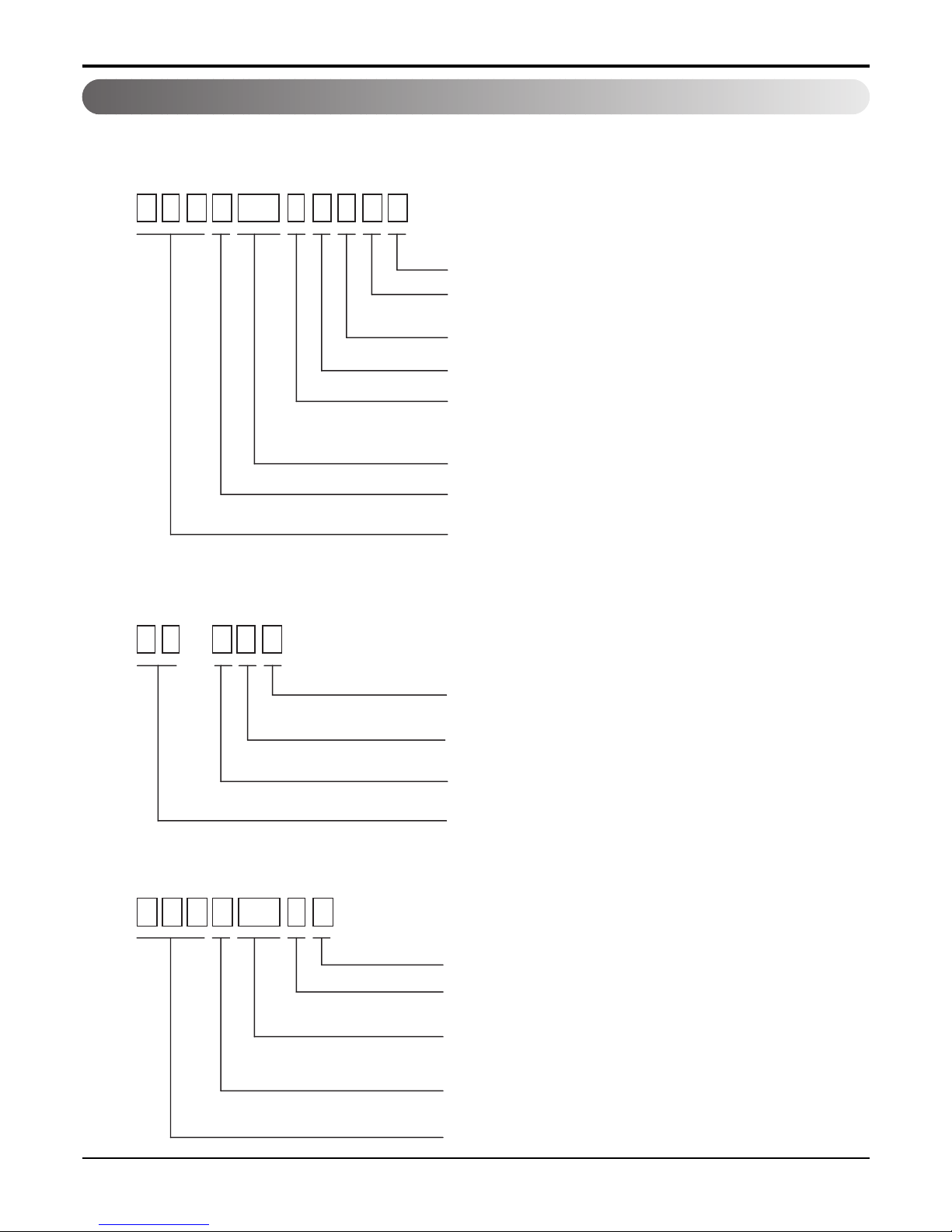

3. Nomenclature ................................................................................................................8

Part 2 Functions & Controls......................................................................................................10

1. List of Functions & Controls......................................................................................11

2. Air flow.........................................................................................................................13

3. Air purifying.................................................................................................................15

4. Installation Functions.................................................................................................16

5. Reliability .....................................................................................................................19

6. Convenience Functions & Controls .........................................................................20

7. Special Function & KIT...............................................................................................31

8. Synchro Operation......................................................................................................48

Part 3 Control logic ....................................................................................................................51

1. Compressor.................................................................................................................52

2. Step(frequency) control..............................................................................................54

3. Reversing valve operaton ..........................................................................................57

4. Discharge pipe control ...............................................................................................58

5. Input Current Control..................................................................................................59

6. Outdoor Fan Control...................................................................................................60

7. Defrost Control............................................................................................................63

8. LEV Control .................................................................................................................64

9. Oil restoration operation ............................................................................................70

10. Compressor warm-up control logic ........................................................................70

11. Heat sink control.......................................................................................................71

Part 4 Test Run ..........................................................................................................................72

1. Check before Test Run ...............................................................................................73

2. Test Run Flow chart ....................................................................................................74

Part 5 Trouble Shooting Guide ................................................................................................77

1. Self-diagnosis Function .............................................................................................78

2. Pump Down .................................................................................................................80

3. Evacuation ...................................................................................................................81

4. Gas Charging...............................................................................................................82

5. Cycle Part.....................................................................................................................83

6. Electronic Parts...........................................................................................................84