- 4 - Copyright © LG Electronics Inc. All rights reserved.

Only training and service purposes.

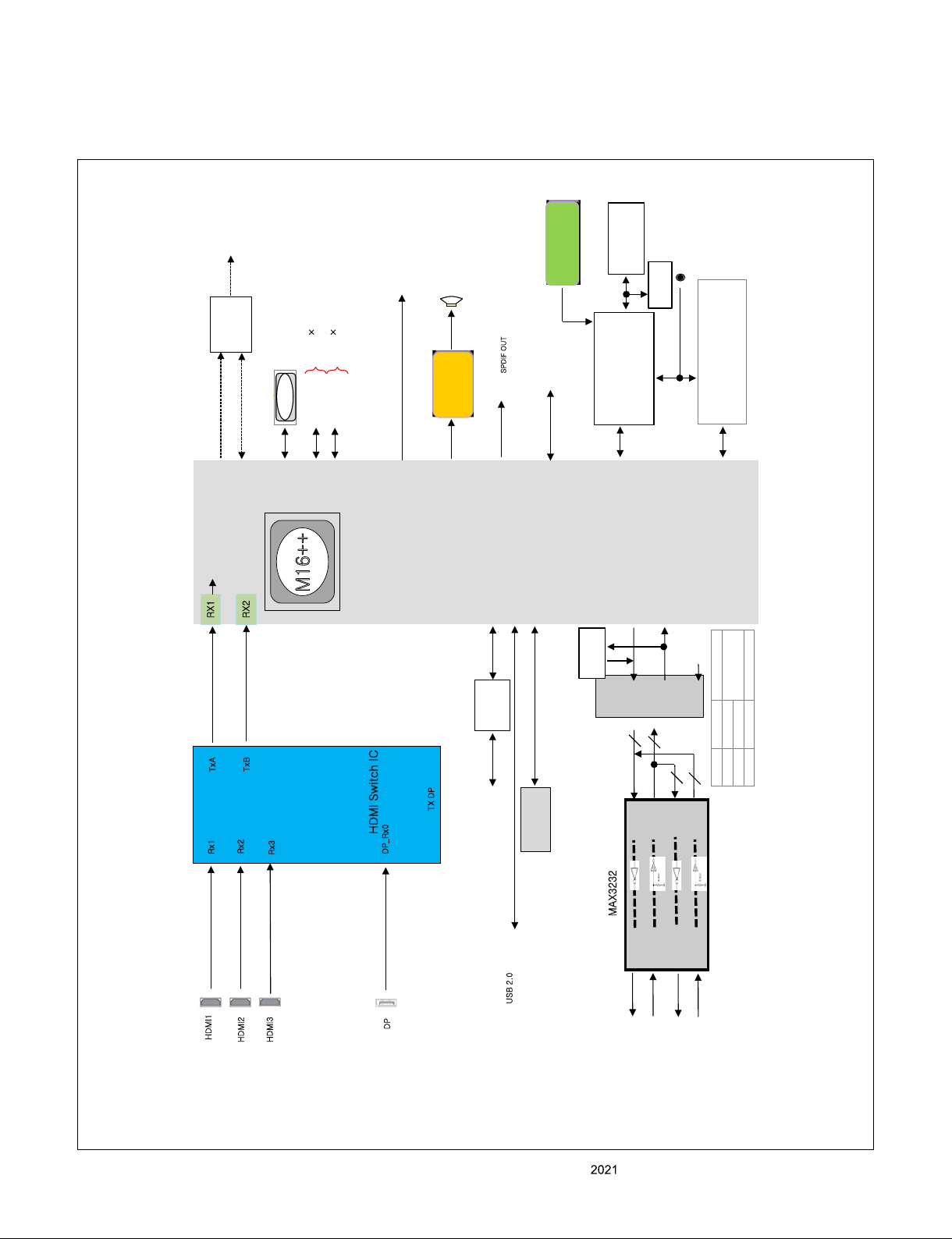

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

explosion hazard.

correctly installed.

7. Always connect the test receiver ground lead to the receiver

lead.

unit under test.

devices.

installed.

SERVICING PRECAUTIONS