Important Safety Instructions

Installation manual 3

ENGLISH

Important Safety Instructions

READ ALL INSTRUCTIONS BEFORE USING

THE APPLIANCE.

Always comply with the following precautions to

avoid dangerous situations and ensure peak

performance of your product.

WARNING

It can result in serious injury or death when the

directions are ignored.

CAUTION

It can result in minor injury or product damage

when the directions are ignored.

WARNING

• Installation or repairs made by unqualified

persons can result in hazards to you and others.

• Installation work must be performed in

accordance with the National Electric Code by

qualified and authorized personnel only.

• The information contained in the manual is

intended for use by a qualified service

technician familiar with safety procedures and

equipped with the proper tools and test

instruments.

• Failure to carefully read and follow all

instructions in this manual can result in

equipment malfunction, property damage,

personal injury and/or death.

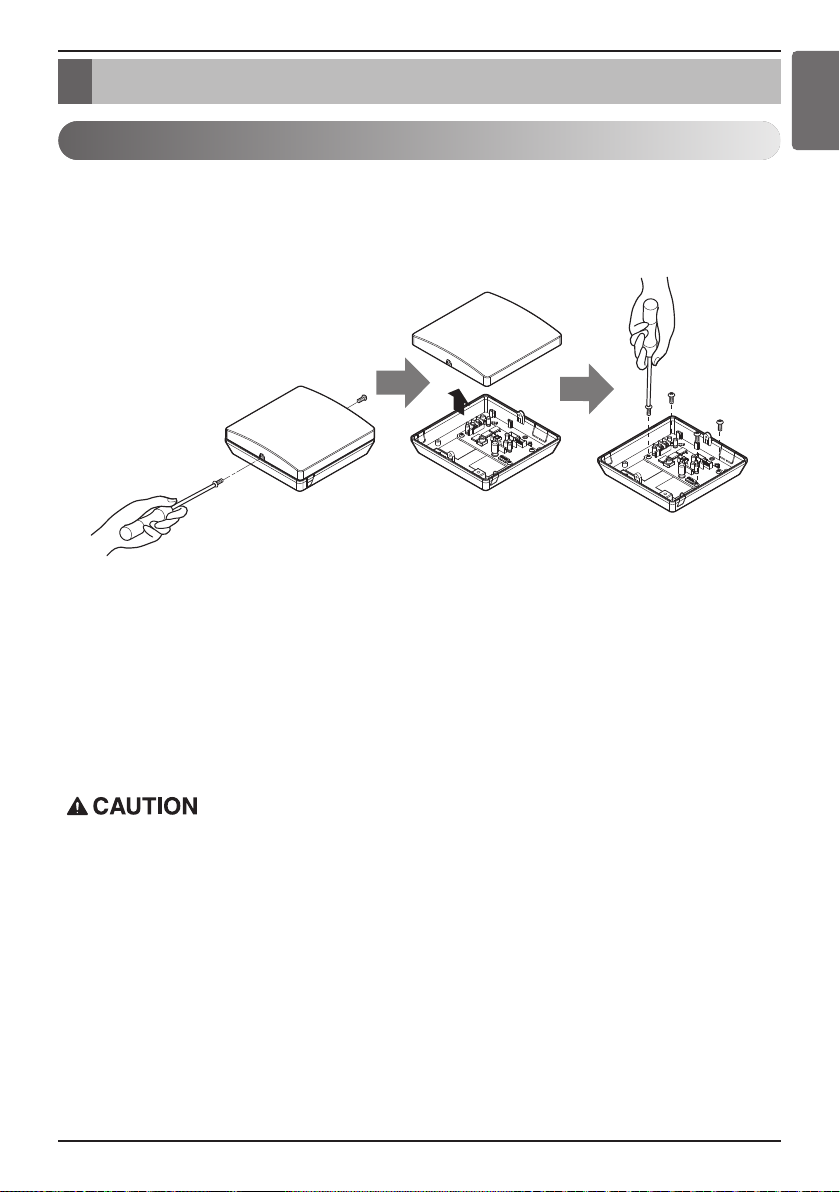

Installation

• Be sure to request to the service center or

installation specialty store when installing

products. It will cause fire or electric shock or

explosion or injury.

• Request to the service center or installation

specialty store when reinstalling the installed

product. It will cause fire or electric shock or

explosion or injury.

• Do not disassemble, fix, and modify products

randomly. It will cause fire or electric shock.

• Be sure to turn off power before installation. It

will cause electric shock.

• Installation work must be performed in

accordance with the national wiring standards

by authorized personnel only.

• Always perform grounding. Otherwise, it may

cause electrical shock.

• You need to use a safely insulated power supply

which follows IEC61558-2-6 anc NEC Class2. If

you do not follow, It may cause fire, electric

shock, explosion or injury.

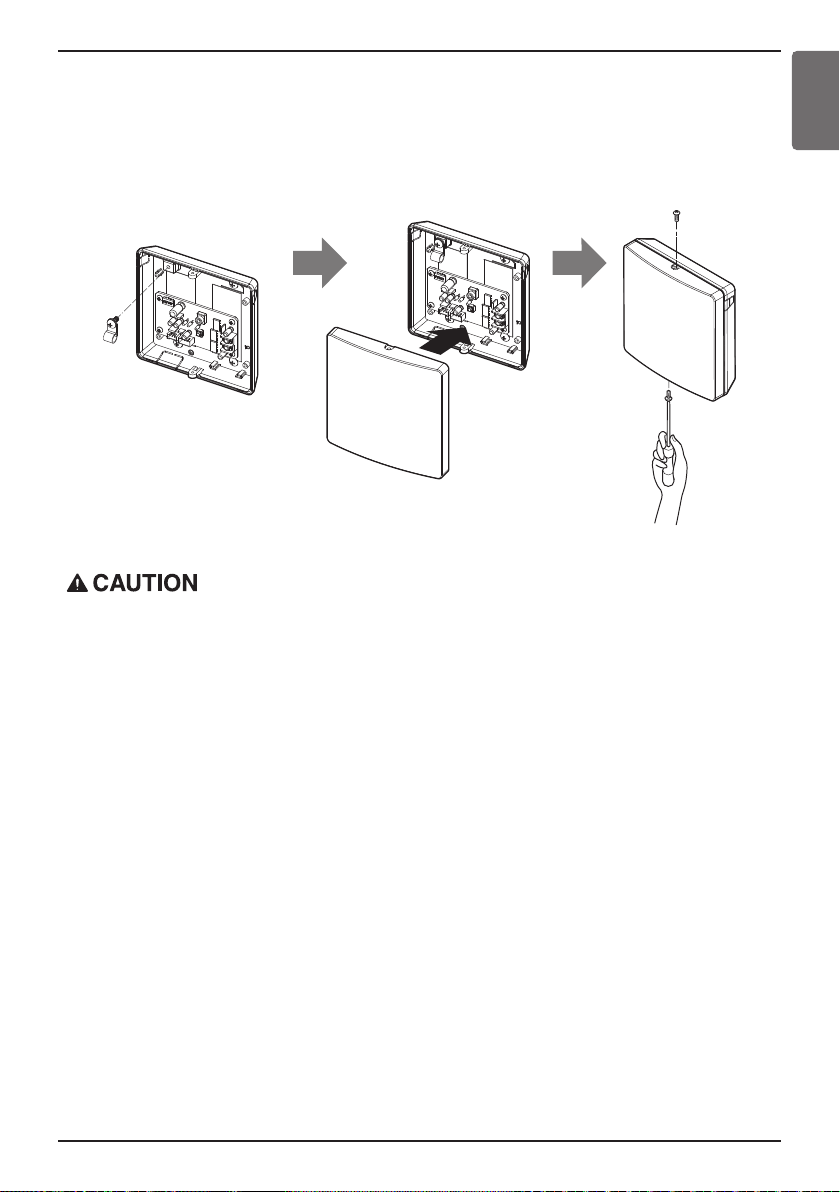

• Securely attach the electrical part cover to

Module. If the electric part cover of Module is

not attached securely, it could result in a fire or

electric shock due to dust, water, etc.

• Make the connections securely so that the

outside force of the cable may not be applied to

the terminals. Inadequate connection and

fastening may generate heat and cause a fire.

In-use

• Do not place flammable stuffs close to the

product. It will cause fire.

• Do not allow water to run into the product. It will

cause electric shock or breakdown.

• Do not give the shock to the product. It will

cause breakdown when giving the shock to the

product.

• Request to the service center or installation

specialty store when the product becomes wet.

It will cause fire or electric shock.

• Do not give the shock using sharp and pointed

objects. It will cause breakdown by damaging

parts.

• Do not touch the board when the power is

connected. It can cause a fire, electric shock,

explosion, injury and problem to the product.

• Unplug the unit if strange sounds, smell, or

smoke comes from it. Otherwise, it may cause

electrical shock or a fire.

• The appliance must only be supplied at safety

extra low voltage corresponding to the marking

on the appliance.

• This appliance is not intended to be accessible

to the general public.

!

!

!