PDP Training - Fall 2008 3

Table of ConTenTs

OVERVIEW .................................................. 5

Introduction ....................................................5

Basic Troubleshooting Steps...........................5

Caution............................................................5

Model Number Structure ...............................6

Serial Number Structure.................................6

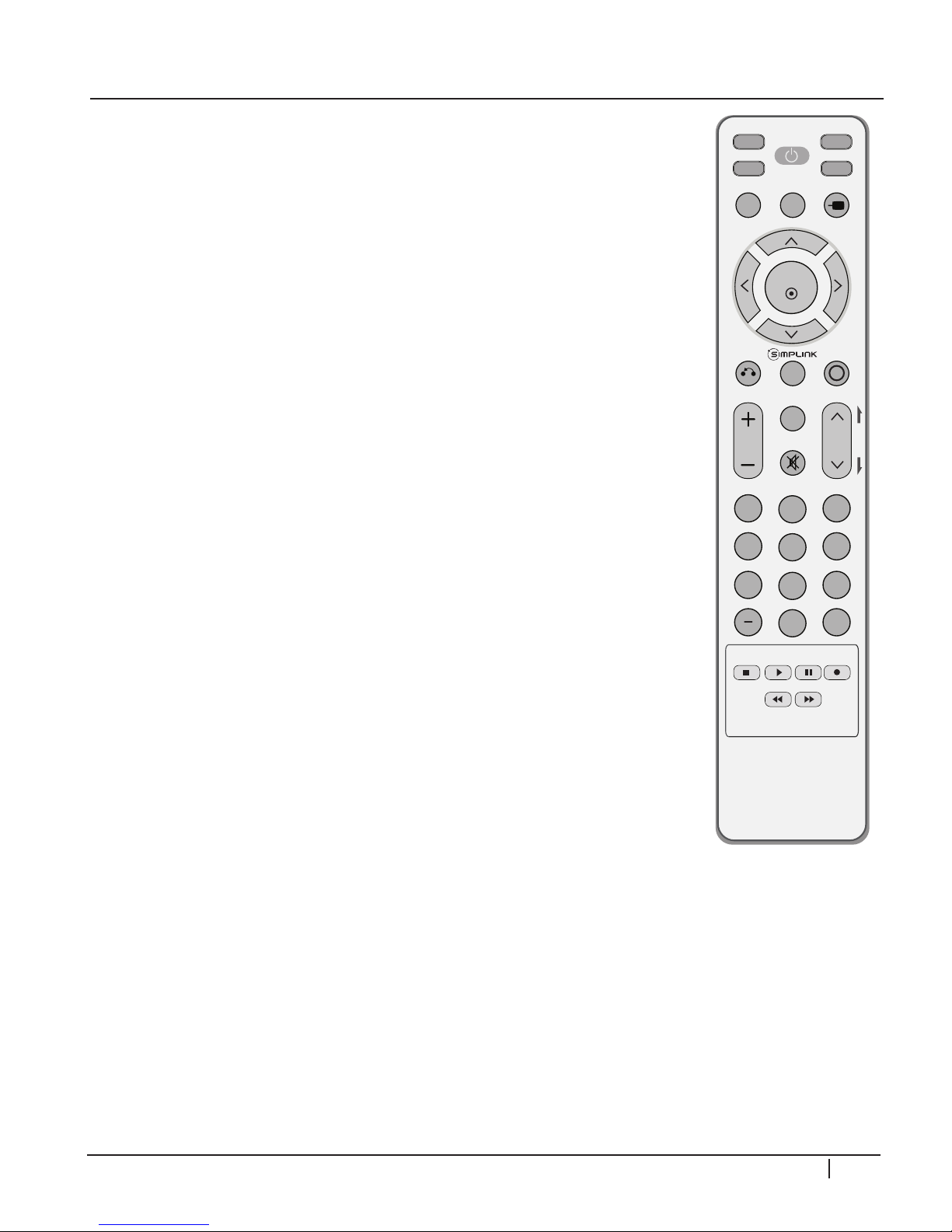

Remote Control ..............................................7

New Features .................................................7

Computer Connection....................................8

Service Menu...................................................8

Power Consumption.......................................8

Service Remote ...............................................9

Check Firmware Version ............................. 10

Update Firmware......................................... 10

42PG20 Dimensions .................................... 11

50PG20 Dimensions .................................... 11

DISASSEMBLY ........................................... 12

Introduction ................................................. 12

Back Cover Removal.................................... 12

Switch Mode Power Supply Removal .......... 13

Y-Sus board Removal.................................... 13

Y-Drive board Removal ............................... 13

Z-Sus board Removal................................... 13

Main board Removal .................................... 13

Control Button Board Removal ................... 13

X-Drive boards Removal.............................. 13

TCP Connector Removal............................. 15

P232 & P331 Connector Removal ............... 15

Control Button board removal .................... 16

42PG20 Exploded View ............................... 17

Block Diagram.............................................. 18

Signal and Voltage Block Diagram ................ 19

CIRCUIT DESCRIPTIONS......................... 20

Introduction ................................................. 20

Adjustment Order **Important**................ 20

Power Supply (SMPS)................................... 21

Y-Sus Board .................................................. 29

Y-Drive Board .............................................. 37

Z-Sus Board ................................................. 42

Control Board.............................................. 44

X-Drive Boards ............................................ 51

Left and Right X-Drive Removal .................. 55

Main (Digital) Board ..................................... 56

Power Switch and Keypad ........................... 61

DISASSEMBLY ........................................... 63

Introduction ................................................. 63

Back Cover Removal.................................... 63

Power Supply Board Removal...................... 63

Y-Sus Board Removal ................................... 64

Top Y-Drive Board Removal......................... 64

Bottom Y-Drive Board ................................. 64

Z-Sus Board Removal................................... 65

Main Board Removal.................................... 65

Control Board Removal ............................... 65

X-Board Removal......................................... 65

TCP connector removal............................... 67

P232 & P331 connector removal................. 67

50PG20 Exploded View ............................... 68

Block Diagram.............................................. 69

Signal and Voltage Block Diagram ................ 70

CIRCUIT DESCRIPTIONS ........................ 71

Introduction ................................................. 71

Adjustment Order **Important**................ 72

Power Supply ............................................... 72

Y-Sustain....................................................... 82

Y-drive .......................................................... 88

Z-Sus Board ................................................. 93

Control Board.............................................. 97

X-Drive Boards .......................................... 102

Left and Right X-Drive Removal ................ 107

Main (Digital) Board ................................... 108

SCHEMATICS .......................................... 111

42PG20 :: Interconnect.............................. 111

42PG20 :: Waveforms ................................ 112

42PG20 :: Main Board :: Video & BCM...... 113

42PG20 :: Main Board :: Control ............... 114

42PG20 :: Main Board :: DDR Memory..... 115

42PG20 :: Main Board :: Tuner................... 116

42PG20 :: Main Board :: Audio Processor . 117

42PG20 :: Main Board :: Power Regulator. 118

42PG20 :: Main Board :: Inputs .................. 119

42PG20 :: Main Board :: HDMI & USB ...... 120

42PG20 :: Power Supply :: PFC & MCU.... 121

42PG20 :: Power Supply :: Multi & Stby..... 122

42PG20 :: Power Supply :: VA & VA .......... 123

42PG20 :: Main Board :: PCB Layout......... 124

42PG20 :: Main Board :: Bottom PCB ....... 125

42PG20 :: Sub Boards :: PCB Layout ......... 126

50PG20 :: Main Board :: Interconnect ....... 127

50PG20 :: Main Board :: Control ............... 128

50PG20 :: Main Board :: Video & BCM...... 129

50PG20 :: Main Board :: Control ............... 130

50PG20 :: Main Board :: DDR Memory..... 131

50PG20 :: Main Board :: Tuner................... 132

50PG20 :: Main Board :: Audio Processor . 133

50PG20 :: Main Board :: Power Regulator. 134

50PG20 :: Main Board :: Interface.............. 135

50PG20 :: Main Board :: HDMI & USB ...... 136

50PG20 :: Main Board :: PCB Layout......... 137

50PG20 :: Main Board :: Bottom PCB ....... 138

50PG20 :: Sub Boards :: PCB Layout ......... 139