LI-820 CO2Analyzer Source/Detector/Optical Path Replacement

The LI-820 CO2Analyzer has a standard 14 cm optical bench for making CO2measurements to 2,000 ppm. An optional 5 cm optical

bench can be installed to obtain a resolution of up to 20000 ppm. Please note that early versions of the instrument (embedded)

software (<1.0.5) had a problem related to automatic loading of the calibration coefficients when switching from the long (14 cm)

optical bench to the short (5 cm) optical bench, and vice versa.

To update the embedded software, you must open the LI-820 and install a programming jumper on the main circuit board, and then

run a software update utility to re-program the instrument’s flash memory. Follow the steps below to install a new source, detector,

and/or optical bench in the LI-820; if your instrument serial number is CGA-161 or below, you will need to follow the instructions on

the following page also, to update your instrument software to V1.0.6.

1. Disconnect the LI-820 power supply. Let the optical bench cool

for about 10 minutes. Remove the six screws on the

LI-820 top panel and remove the cover.

2. Unscrew the tube retaining nuts on the inner air port fittings.

Remove the tubing from both air ports. Leave the tubing

connected to the source and detector housings.

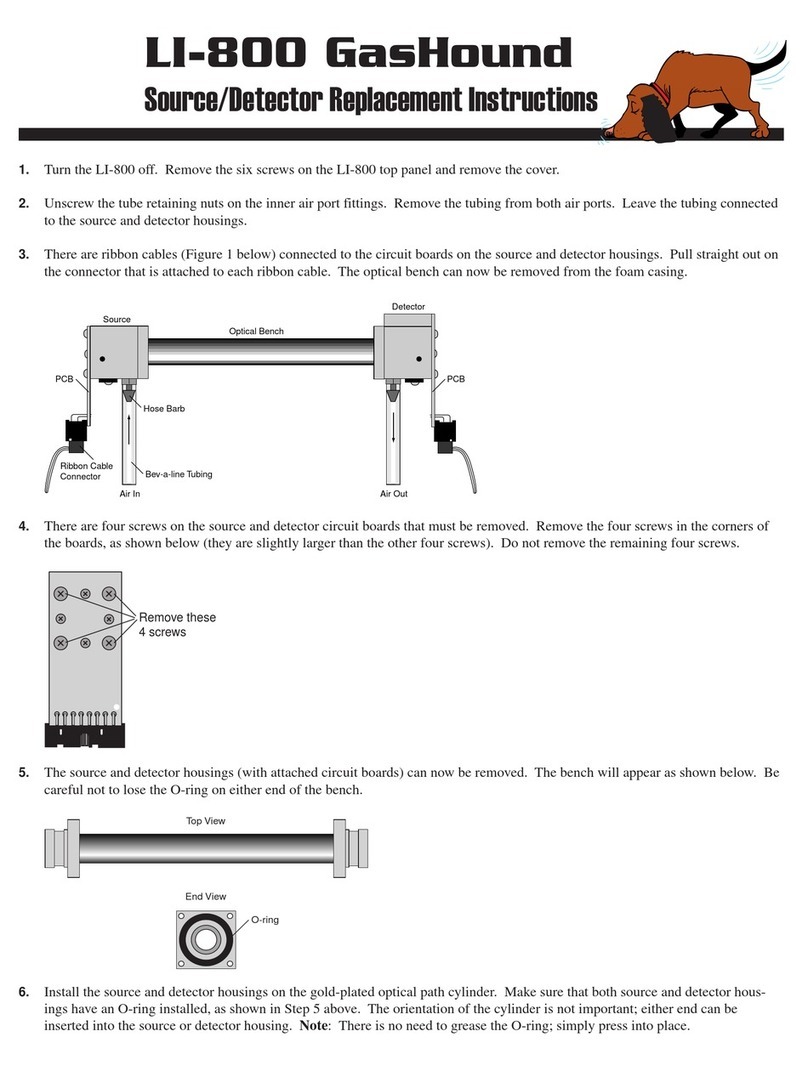

3. There are ribbon cables (Figure 1) connected to the circuit

boards on the source and detector housings. Pull straight out on

the connector that is attached to each ribbon cable. The optical

bench can now be removed from the foam casing.

4. There are four screws on the source and detector circuit boards

that must be removed. Remove the four screws in the corners of

the boards, as shown in Figure 2 (they are slightly larger than the

other four screws). Do not remove the remaining four screws.

5. The source and detector housings (with attached circuit boards)

can now be removed. The bench will appear as shown in Figure

3. Be careful not to lose the O-ring on either end of the bench.

Make sure the optical path tube is clean (no dust, dirt, etc.)

before proceeding.

6. Install the source and detector housings on the gold-plated

optical path cylinder. Make sure that both source and detector

housings have an O-ring installed, as shown in Step 3. The

orientation of the cylinder is not important; either end can be

inserted into the source or detector housing. Note: There is no

need to grease the O-ring; simply press into place.

7. Carefully remove the 10-pin connector that was attached to the

source housing circuit board from the main circuit board.

Reattach the 10-pin connector to one of the connectors shown in

Figure 4, depending on the length of the optical bench being

installed.

8Install the bench with the source side on the left as you face the

front of the instrument.

9. Reattach the 10-pin connectors to the source and detector

housing circuit boards. Reattach the Bev-a-line tubing to the

hose barbs on the source and detector housings, and to the flow

in and out ports, if necessary.

10. Re-assemble the LI-820 case. Make sure that the foam insula-

tion on the inside top cover is positioned over the optical bench;

it is required for thermal stability.

12. Perform zero and span calibrations as described in the LI-820

Instruction Manual Section 3, Calibration Window.

3

1

2

3

4

Remove these 4 screws

Source Detector

Air tube

fittings

Ribbon cable

connector

Ribbon cable

connector

5 cm bench

connector

Make sure the O-ring

is in place on both ends

of the optical bench (5 cm

bench shown)

5 cm bench

source connector

14 cm bench

source connector