10

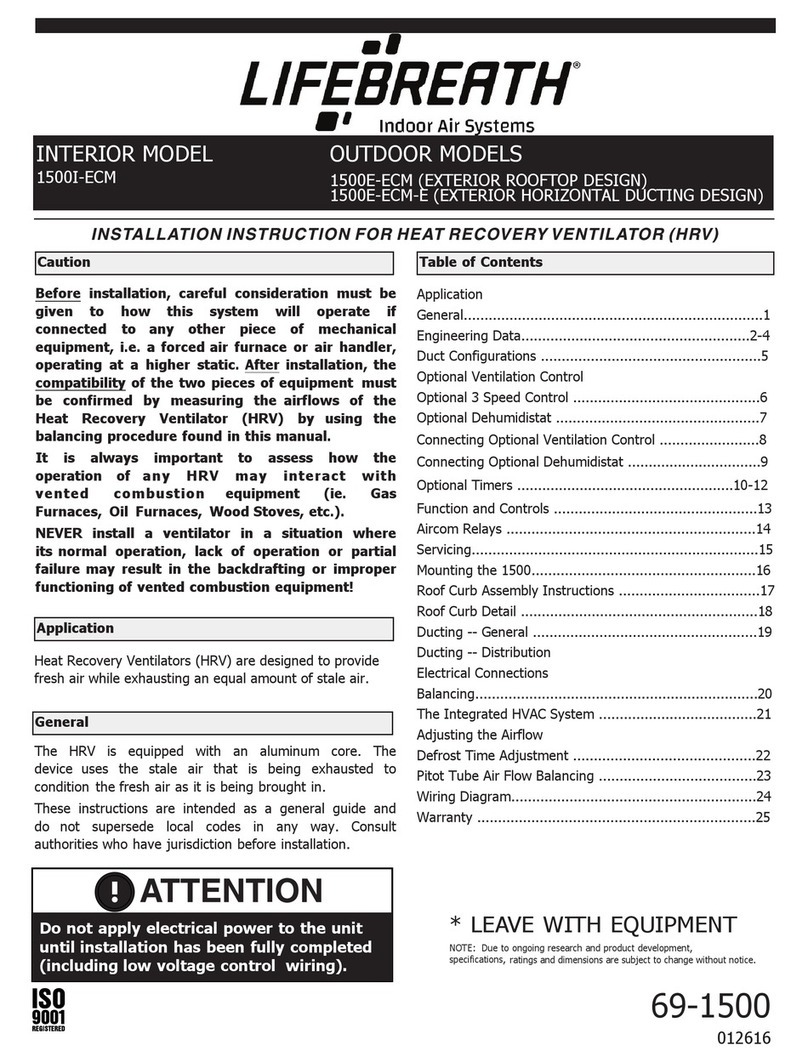

It is necessary to design and size the duct

distribution system for both the supply and the exhaust

air streams.

Proper duct design & duct sizing will:

•Minimize air flow requirements.

•Ensure a comfortable environment by using reheat if

required.

•Optimize humidity control, including eliminating

condensation on windows by blanketing the windows

with airflow.

Refer to Sample Duct Layout 1 and 2 for typical

duct system designs.

All joints must be airtight, sealed and impervious to

moisture. See specification sheets for each unit for

exact duct sizes and location.

To minimize pressure drop and noise, galvanized

metal ducts, properly sized, are recommended. Keep

ducting as short as possible and use a minimum of

elbows and tees. Connecting sections and shorter

runs may be flexible ducting one size larger than the

metal equivalent. Use flexible duct connectors at

the HRV to avoid noise transmission.

All duct joints must be secured with screws, rivets or

duct sealant and sealed with aluminum duct tape to

prevent leakage.

The weatherhoods must have built-in “bird” screen with

1/4 in (6.35 mm) minimum mesh to prevent birds and

rodents from entering into the ductwork. Do not use

smaller mesh as it will be very susceptible to plugging

up. Gravity dampers at the vents must not be used as

they will restrict air flow and often “seize up”. The

preferred location of the outside weatherhoods is:

•no less than 10 ft. (3 m) apart from each other

•at least 18 in (46 cm) above snow line or ground

level

•away from sources of contaminants, such

as automobile exhaust fumes, gas meters, garbage

cans, containers, etc.

•not exposed to prevailing winds

The outside perimeter of the weatherhood must be

caulked to prevent leakage into the building.

The design and size of the weatherhoods or louvers

chosen by the installer must allow for adequate free

area. Water and snow penetration of the system is

minimized when the airflow does not exceed 1000

FPM (5.08 m/s) free area velocity.

Ducting from the Weatherhoods

Galvanized sheet metal ducting with sufficient cross

section with an integral single piece vapor barrier

should be used to connect the HRV to the

weatherhoods.

All ducting must meet UL Class 1 requirements.

A minimum R value of insulation should be equal to

4 (RSI 0.75).

A good bead of high quality caulking (preferably

acoustical sealant) and taping with a high quality

aluminum foil tape is recommended to seal the duct

to both the HRV and the weatherhood.

Warm-side Ducting - General

Ducting from the HRV to the different areas in the

building should be galvanized metal whenever possible.

To minimize airflow losses in the ductwork system, all

ducts should be as short as possible and with as few

bends or elbows as possible. 45° elbows are preferred

to 90° elbows. Use “Wye” (Y) fittings instead of

“Tees” (T) whenever possible.

All duct joints must be fastened with screws, rivets or

duct sealant and wrapped with a quality duct tape to

prevent leakage. We recommend aluminum foil tape.

The Ductwork System

Outside Weatherhoods

Fully insulated ducting with an

integral vapour barrier must be used

on all runs passing through unheated

areas in order to avoid condensation

problems and energy losses from the air

systems.

ATTENTION