N24 Installation Manual

4 5

9

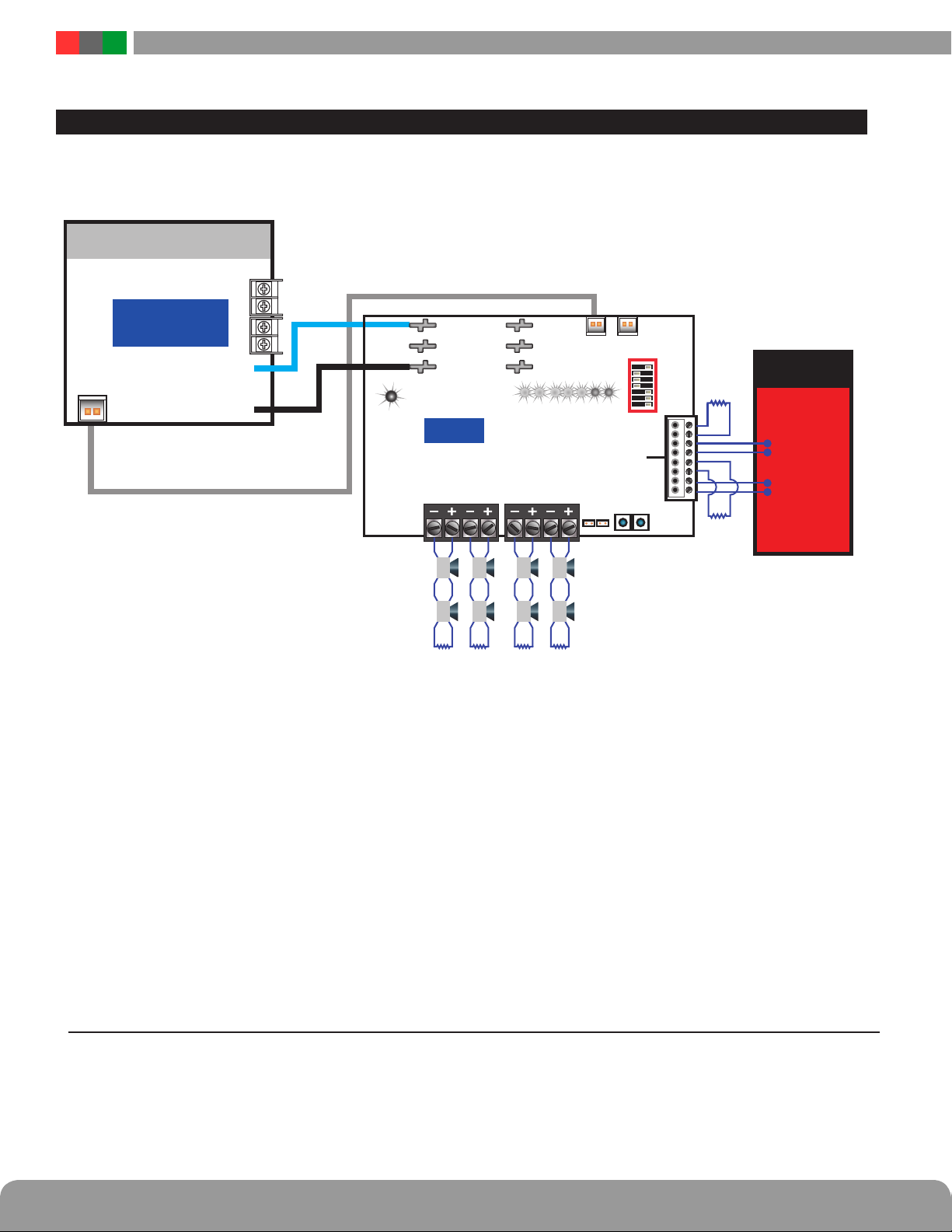

Zone Inputs (TB3)

The inputs for activating the outputs of the N24 board. The

usage of these inputs varies based on the settings of the DIP

switches – see DIP Switch settings for more information

(item 10).

• INxA EOL (Class B) or Return + (Class A)

• INxB EOL (Class B) or Return – (Class A)

• INxC Input -

• INxD Input +

(See input example wiring diagrams for details on Page 4.)

These terminals are not supervised by the N24 board -

supervision of these terminals and the entire input loop is

performed by the FACP.

These terminals are removable and accept wire sizes from

AWG14-AWG22.

bk

Configuration DIP Switches (SW3)

These switches configure the operation of the N24 board.

Note that Switches 1 and 2 MUST be ON when using any of

the Output Synchronization Protocols.

Refer to the chart below for settings:

b

FlexIO Connection

This connector supplies the fault and FAI status between the

FPO power supply system and the N24 board. The appropriate

cable is supplied with the N24 board. See the FPO power supply

manual for more information.

b

Input Power LED

This LED indicates that power is available at the input of the

N24 board. If this LED is not lit, check the Input Fuse of the

N24 and voltage at the B1/B2 power input.

b

Status LEDs

These LEDs indicate the status of the N24 board as follows:

IN1 / IN2 Light RED when a valid signal is received at

the corresponding input terminals. These

LEDs may flash if a coded input is applied

to the respective input.

OUT1 - OUT4 Light YELLOW if a fault is detected on the

corresponding output terminals. Faults

detected include open, short, or overcurrent.

COMFLT Lights YELLOW if any fault condition

is detected by the N24 board. Faults

detected include open or shorted outputs,

output overcurrent, and invalid Dip switch

configurations.

N24 – Accessory Overview

Switch Number

1234567

Input Configuration

IN1 controls all outputs Off Off

IN2 not used

IN1 controls all outputs Off On

IN2 controls all outputs

IN1 controls OUT1 and OUT2 On Off

IN2 controls OUT3 and OUT4

Use this setting when using an

Output Synchronization Protocol setting On On

IN1 controls strobes

IN2 controls horns (only when IN1 is also active)

Output Wiring Configuration

Four Class B Outputs (OUT1, 2, 3, 4) Off Off

Two Class A Outputs (OUT1-2 & OUT3-4) Off On

Two Class B (OUT1, 2)

and One Class A Output (OUT3-4) On Off

One Class A Output (OUT1-2) and Two Class

B Outputs (OUT3,4) On On

Output Protocol Configuration

Steady (follower mode) on OUT1 and 2 Off Off Off

ANSI Temporal Code on OUT3 and 4

ANSI Temporal Code on OUT1, 2, 3, 4 Off Off On

Gentex Synchronization Protocol Off On On

Wheelock Synchronization Protocol On Off On

AMSECO/Potter Synchronization Protocol On On Off