CONTENT

Ⅰ.Power System ..................................................................................................................... 1

1.Engine for Forklift........................................................................................................... 1

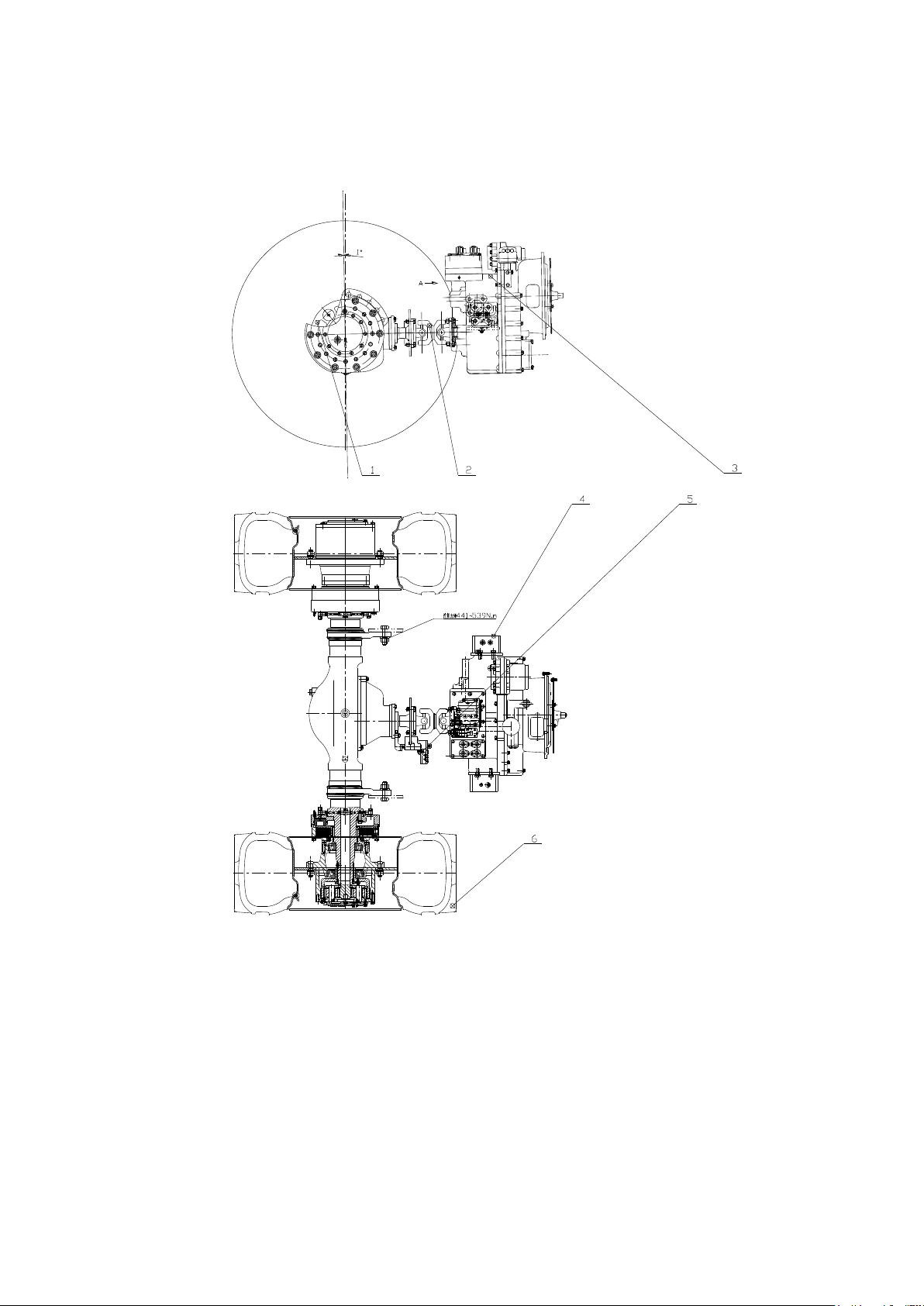

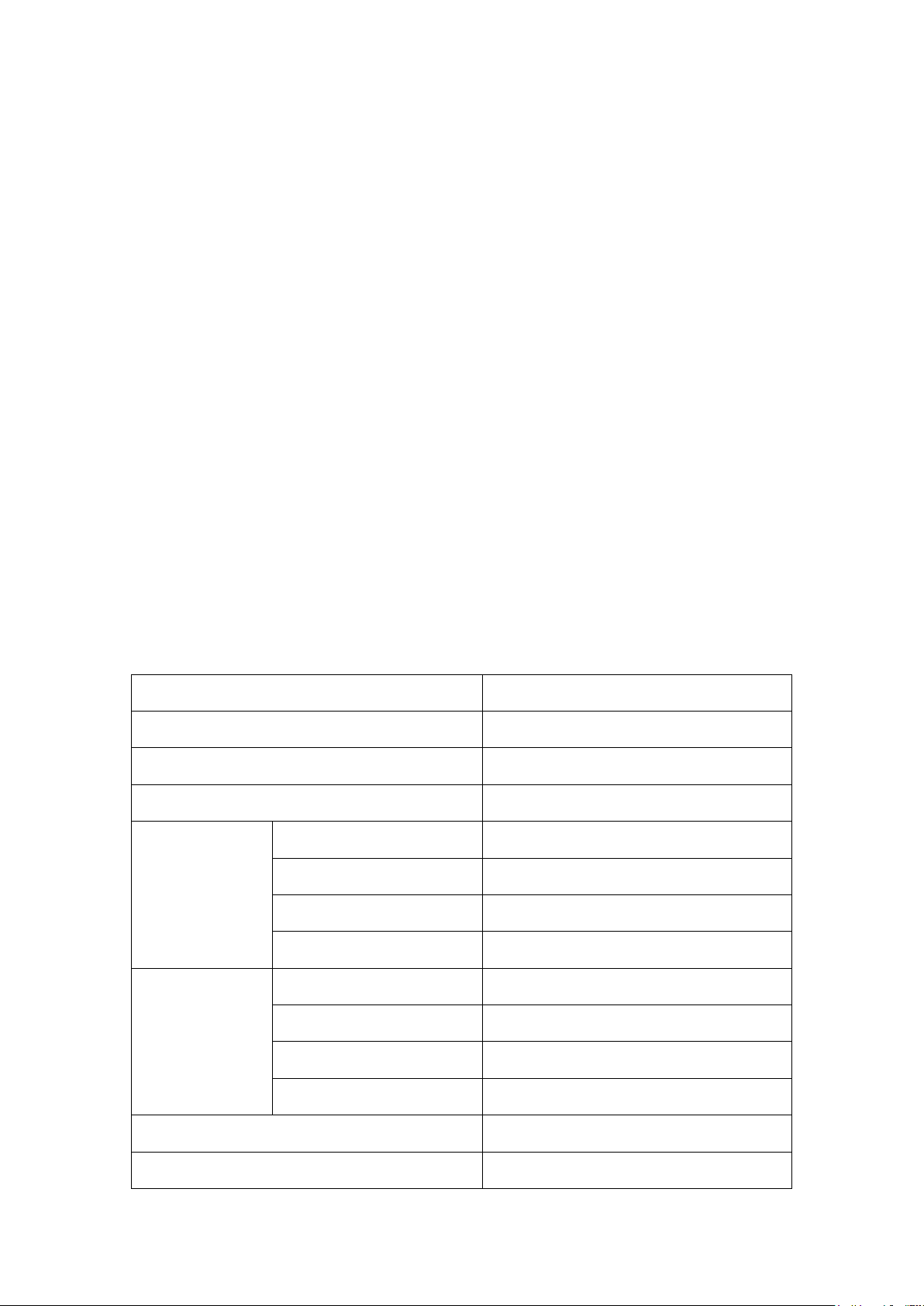

Ⅱ.Drive system ....................................................................................................................... 2

1.Summarize..................................................................................................................... 2

2. Hydrodynamic power transmission gear-box ................................................................ 4

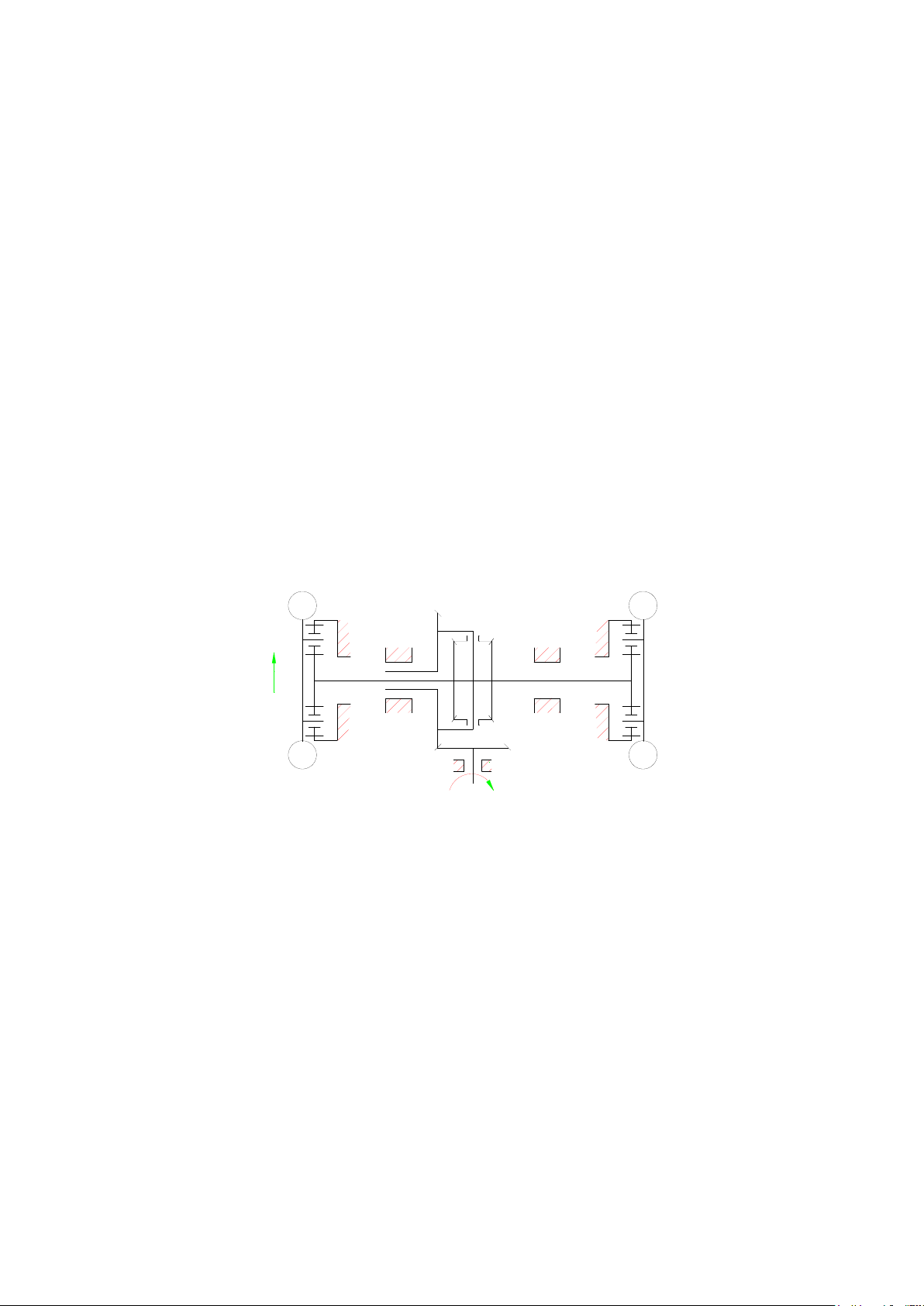

3. Driving axle..................................................................................................................... 6

ⅢSteering system.................................................................................................................. 13

1 Structure introduction ................................................................................................. 13

Ⅳ.Brake system...................................................................................................................... 26

1.Data............................................................................................................................... 26

2.Fault diagnoses and corrections................................................................................... 27

3.Brake inching pedal adjustment.................................................................................... 29

4.Brake valve and accumulator........................................................................................ 30

5.Hand brake.................................................................................................................... 32

6.Service brake................................................................................................................ 38

7.Hydraulic brake malfunction diagnosis......................................................................... 40

8.Exhaust of air in the hydraulic system.......................................................................... 40

Ⅴ.Hydraulic system ................................................................................................................ 40

1.Oil pump........................................................................................................................ 40

2.Multiple directional control valve................................................................................... 42

3.Rotary type piping filter ................................................................................................. 50

4.One-way governor valve............................................................................................... 50

5.Lifting cylinder............................................................................................................... 50

6.Tilting cylinder ............................................................................................................... 51

7.Air exhaust in hydraulic system .................................................................................... 51

8.Hydraulic system fault diagnosis and corrections......................................................... 52

9.Hydraulic system schematic diagram........................................................................... 53

Ⅵ. Lifting system..................................................................................................................... 54

1.Assemble debugging data ............................................................................................ 55

2.Fault diagnosis and corrections.................................................................................... 56

3.Summary....................................................................................................................... 61

4.Mast dismantle and install adjustment.......................................................................... 62

5.Disassembly and installation of lifting cylinder ............................................................. 67

6.Disassembly and installation of tilting cylinder ............................................................. 68

7.Noticing proceeding of debugging................................................................................ 69

Ⅶ.Electrical system ................................................................................................................ 70

1.Control box assembly.................................................................................................... 70

2.Instrument,sensor and relay ......................................................................................... 71

3.Lighting system............................................................................................................. 74

4.Electrical system diagram............................................................................................. 80