Please note that the risks involved for users when using the forklift truck are, in particular:

Risk of loss of control, risk of loss of lateral and frontal stability of the forklift truck.

The operator must stay in control of the forklift truck. In the event of the lift truck overturning, do not try to leave the cab during the incident.

YOUR BEST PROTECTION IS TO STAY FASTENED IN THE CAB.

Fuses and relays

In the cab

See the lift truck's operator's

manual for the full list of fuses.

Under engine cover

Securing

Fix the chocks to the platform at the front and at the back of each tyre.

Also fix the chocks to the platform on the inside of each tyre.

Strap the lift truck to the flatbed, using the anchorage points 1 provided.

In order to ensure the lift truck is securely lashed to the flatbed, observe the lashing angles (α) and

(β) and the resistance (LC) of the straps.

Tighten the straps.

Reading a load chart

1 - Load lifting height.

2 - Load outreach distance.

3 - Zone accessible depending on the load.

4 - Zone inaccessible.

Read the function sheets for the load charts and hydraulic

controls.

Comply with the load chart(s).

1

2

3

4

Attachments

See the lift truck's operator's manual for

gripping device and list of attachments.

Before any use, ensure that the attachment is properly locked

Daily maintenance

Carry out a general inspection

around the lift truck. Check the engine oil level. Check the coolant level. Check the fuel pre-filter. Check the longitudinal stability

limiter and warning device.

Scan for more

information.

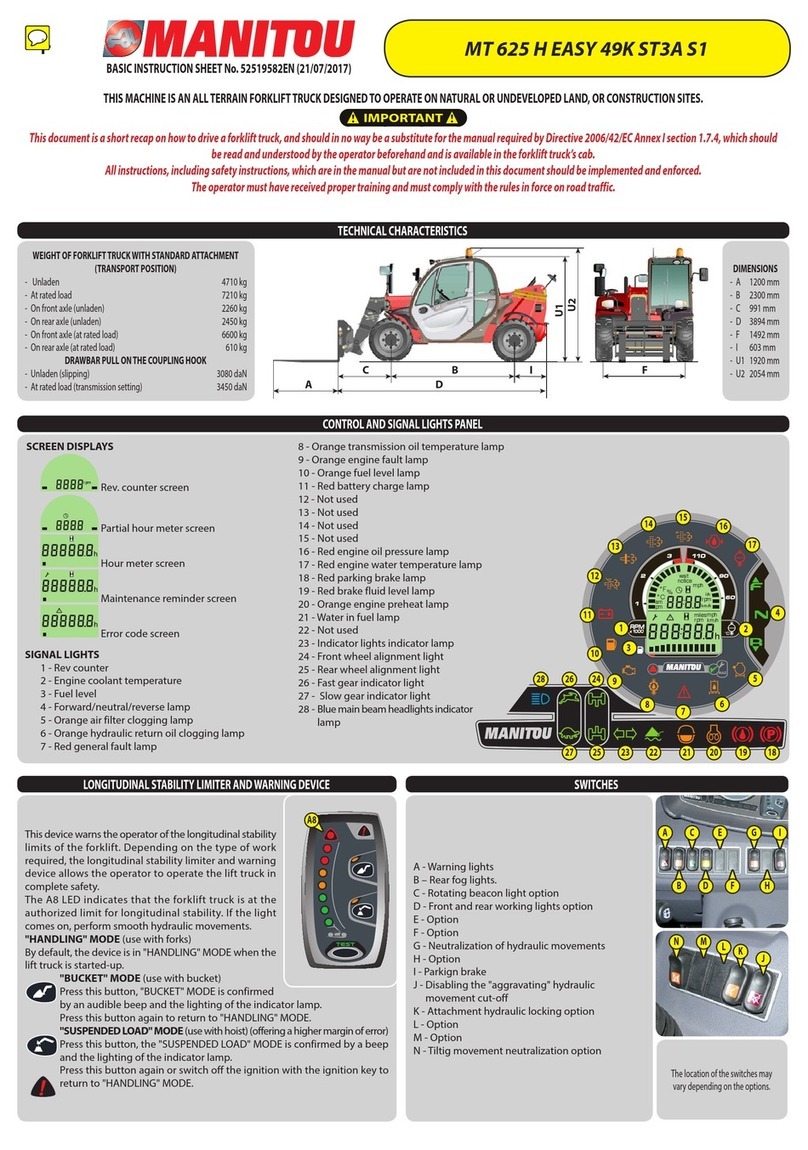

This device warns the operator of the forklift truck’s longitudinal stability limits.

Depending on the type of work required, the longitudinal stability limiter and warning device allows the operator to operate the lift truck in complete safety.

Lamp A8 indicates that the forklift truck is at the authorised longitudinal stability limit.

If the indicator lamp comes on, perform the “deaggravating” hydraulic movements.

"HANDLING" MODE (USE WITH FORKS)

By default, the device is in “HANDLING MODE each time the lift truck is started.

"BUCKET” MODE (USE WITH BUCKET)

Hold down the button, "BUCKET" MODE is confirmed by an audible signal and the indicator lamp coming on.

Press this button again or switch off the ignition with the ignition key to return to "HANDLING” MODE.

"SUSPENDED LOAD" MODE (USE WITH HOIST) offering a higher margin of error.

Hold down the button, "SUSPENDED LOAD" MODE is confirmed by an audible signal and the indicator lamp coming on.

Press this button again or switch off the ignition with the ignition key to return to "HANDLING” MODE.

A permanently lit fault indicator, accompanied by an audible signal, indicates a major fault likely to affect the safety of the forklift truck.

Contact your agent or dealer.

A8

Longitudinal stability limiter and warning device

Hydraulic controls

1-HYDRAULIC CONTROLS ACTIVATION

1

A

B

C

D

A-Lifting and tilting control lever.

B-Telescoping control button.

C-Attachment control button.

D-Control button (OPTION).