PMW20

14

PMW20

15

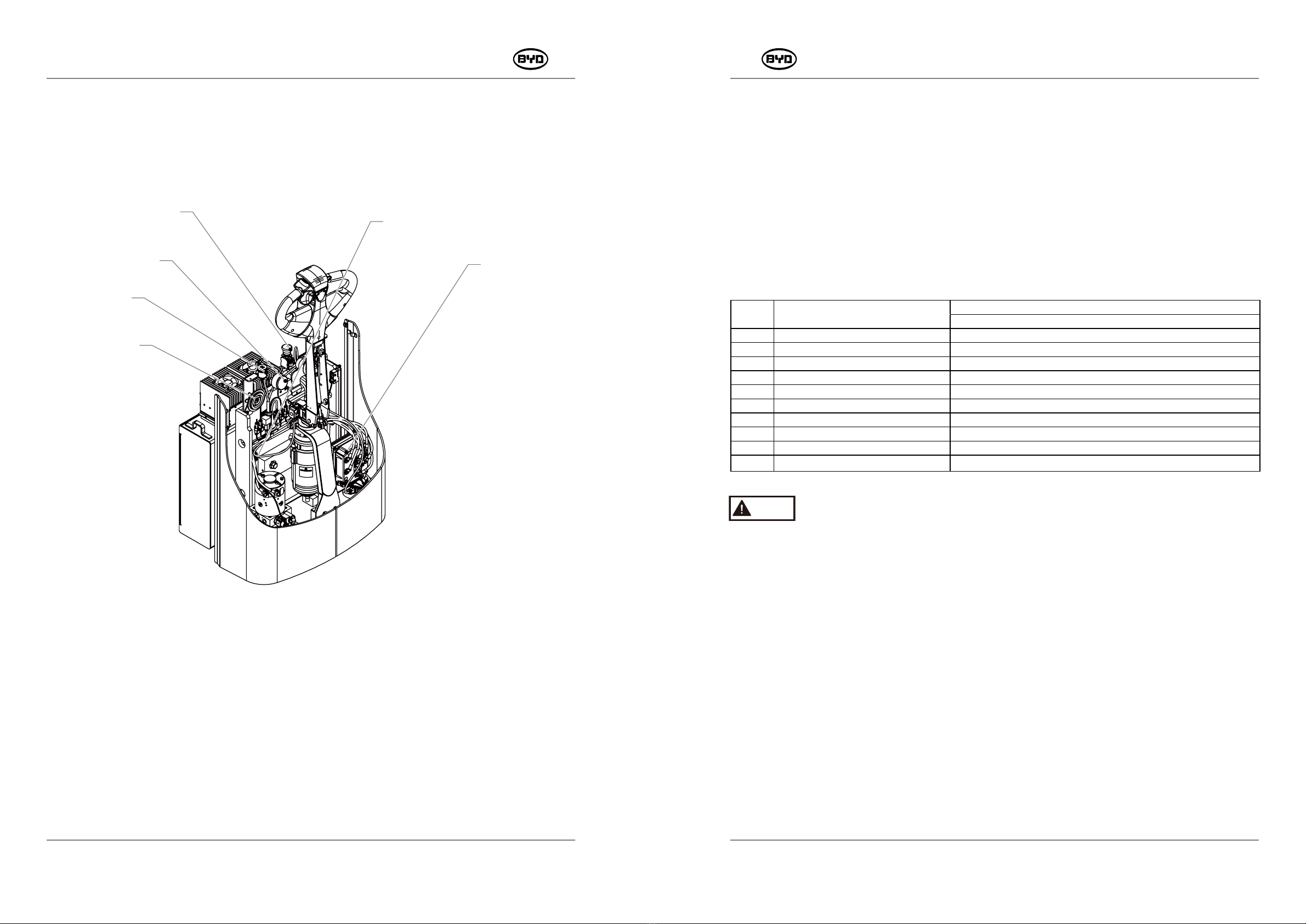

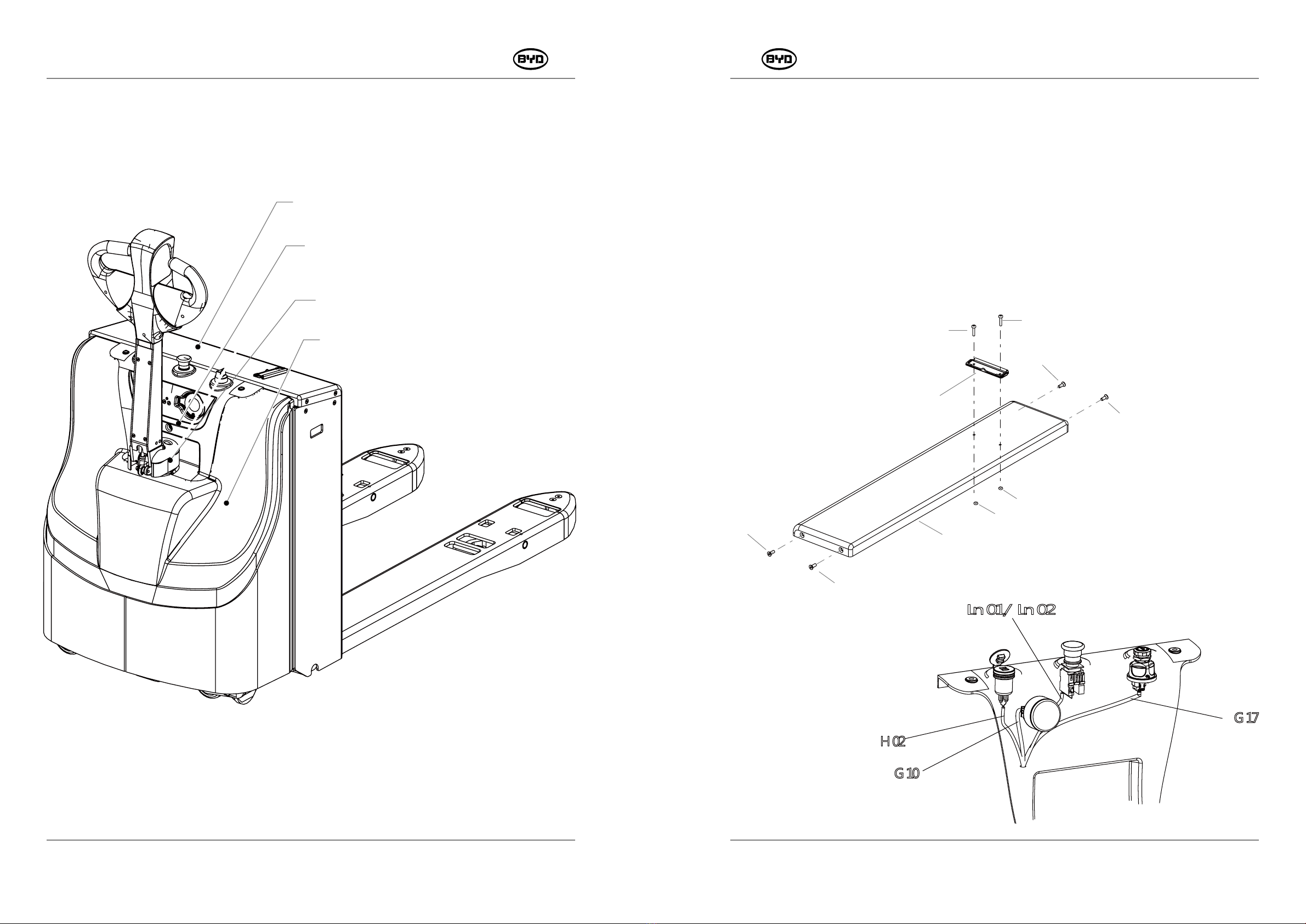

2.2 DESCRIPTION

1. Shape

(1) Check whether the forklift is damaged or deformed.

(2) Check whether oil is leaked on the ground where forklifts are put.

(3) Check whether nameplates or signs are complete.

(4) Check whether parts are loose or fall off.

Note

If oil leaks, please identify the position and contact after-sale personnel of BYD.

2. Wheels

(1) Check whether the fastener of wheels is loose. If yes, tighten it.Remove debris

embedded in the tire.

(2) If wheels are worn seriously wherein the wear between left and right wheels are

uneven, or rims are found broken or bent, please replace wheels.

3. Hydraulic Device

Check the device through the level of hydraulic oil.

4. Instrument

(1) Check whether the battery voltage and power on the instrument are displayed

normally.

(2) Check whether a fault indicating lamp appears on the instrument.

5. Warning Device

(1) Press "horn" button and check whether the horn can honk.

(2) Check whether other warning devices are working normally.

6. Brake Performance

Put the handle lever in the brake area and check whether the brake performance is good.

7. Driving, Steering and Checking

(1) Swing the control handle right and left and up and down. Check whether it can rotate

smoothly and make sure no abnormal sound appears in the operation process.

(2) Check whether buttons can work normally.

(3) Check whether fasteners are loose or fall off.

8. Electric Check

(1) Check whether connection terminals of electric device are loose. If any, tighten it.

Check whether joints among the wiring-connected sections are abnormally.

(2) Check whether the safety device of the master controller works normally. If necessary,

replace it.

(3) Check whether the copper bar of the master controller is burned. If

necessary, replace it.

(4) Check whether the low-voltage insurance and relay can work normally. If

necessary,replace them.

SM-PMW202020001-EN SM-PMW202020001-EN