~ 7 ~

-Lower the fork to the lowered position.

-Close the electric lock and emergency stop switch.

3. Maintenance and charging of storage battery

-When the electricity indicator of the forklift indicates that the electricity of the battery is

insufficient, charging should be conducted at once. Otherwise the battery will be

damaged.

-Close the electric lock and emergency stop switch, connected with charge cable and

charging socket and then connected with the plug and power socket to start charging.

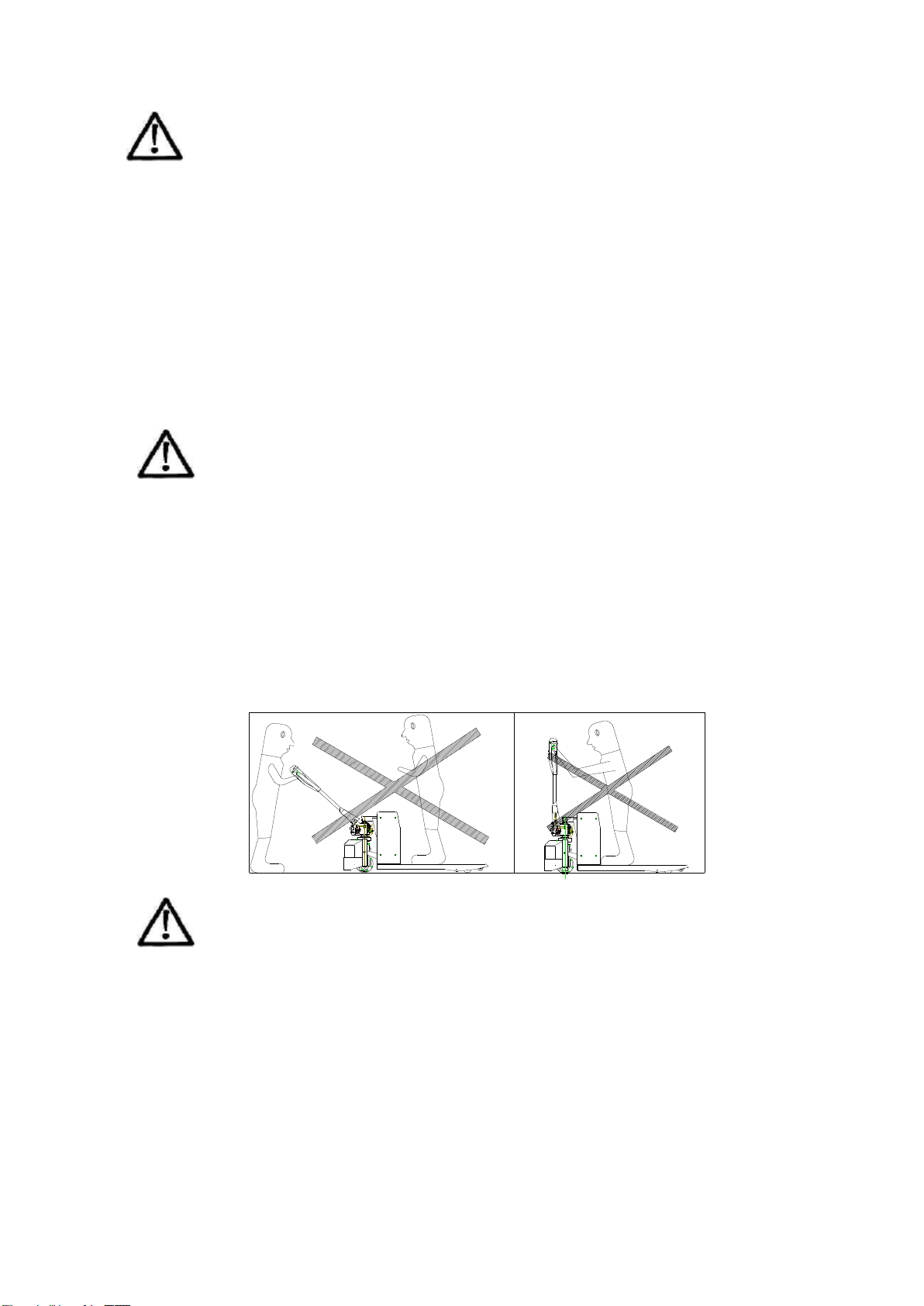

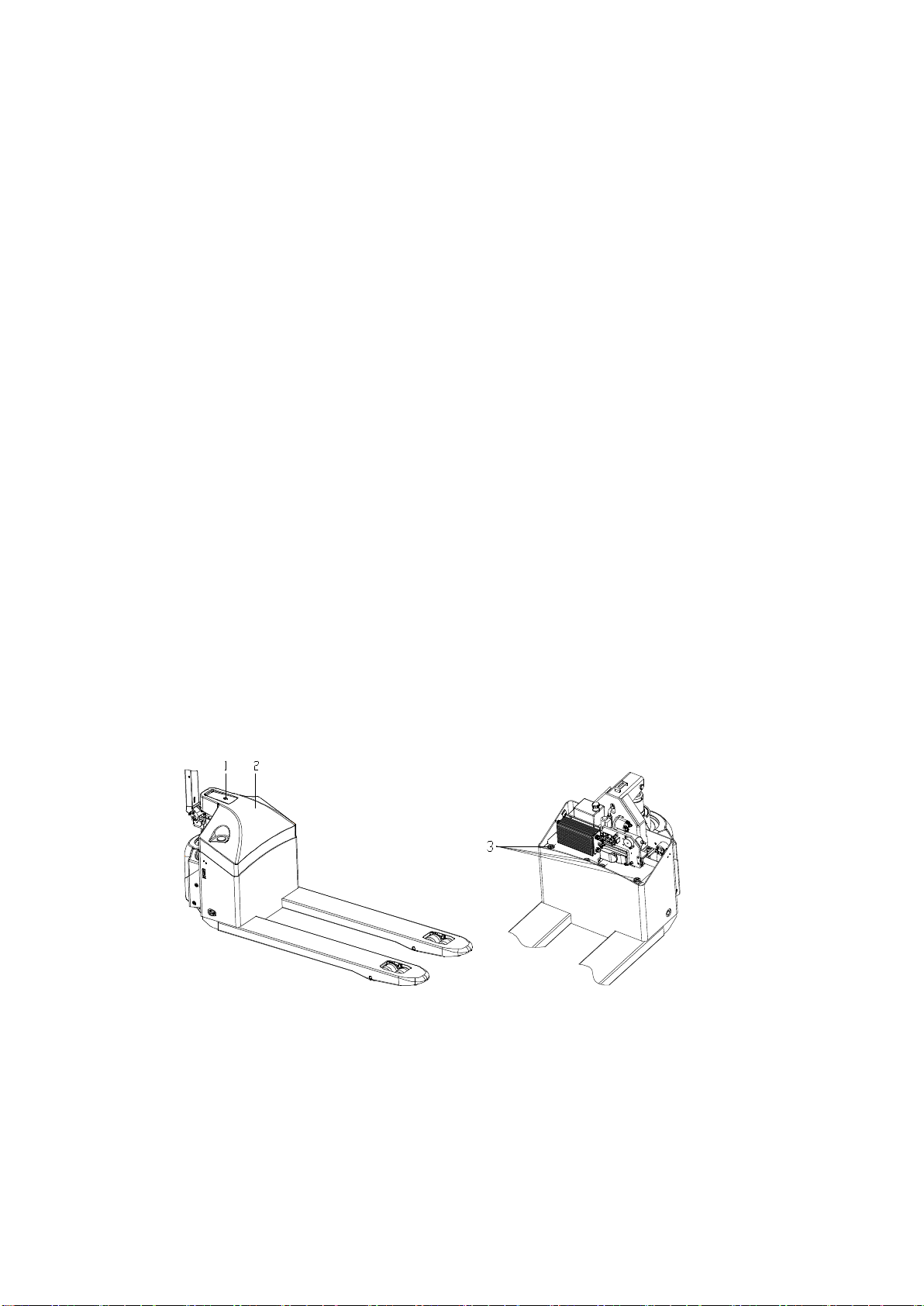

Fig 5

-When the green pilot light of the charger turns on, it indicates that the battery is fully

charged and in that case, the connecting cable can be pulled out and insert the socket into

the truck. Then the forklift is in ready state.

-If the battery is completely discharged, full charging must be conducted (about 12h).

-After discharging, the storage battery cannot be placed for a long time and charging

should be conducted as soon as the battery is discharged.

-When the forklift is not in operation, the general power supply must be turned off, the

electric lock must be pulled out and one supplementary charging must be conducted every

five months during the period when the forklift is in storage.

-It is strictly prohibited to open the storage battery air vent valve; otherwise, poor sealing

will be caused and the capacity and service life of the battery will be affected.

5. Maintenance

-5.1If the forklift is able to operate satisfactorily depends on careful maintenance.

-When maintenance is neglected, human safety may be endangered and property may be

damaged. When the truck is in operation, routine inspection should be conducted

frequently and abnormal should be removed in time. Do not operate forklift with trouble to

ensure safety and prolong the service life of the forklift.

-5.2 Maintenance: The maintenance of the forklift is usually divided into three levels,

routine maintenance, level 1 maintenance and level 2 maintenance.

-Routine maintenance: Once everyday and the main content are to keep the surface clean

and examine if the power supply cable is damaged.

-Level 1 maintenance: Once every week. The maintenance contents, besides the contents

of routine maintenance, should focus on if the operation of the components is normal, if

the fastening items are loose, if there is any oil leakage, if there is any abnormal wearing in

mechanical components, if there are abnormal temperature rise or sparks in electric

equipment, etc. Adjustment and trouble shooting should be conducted if any abnormal

Electricity shortage, immediately

charging