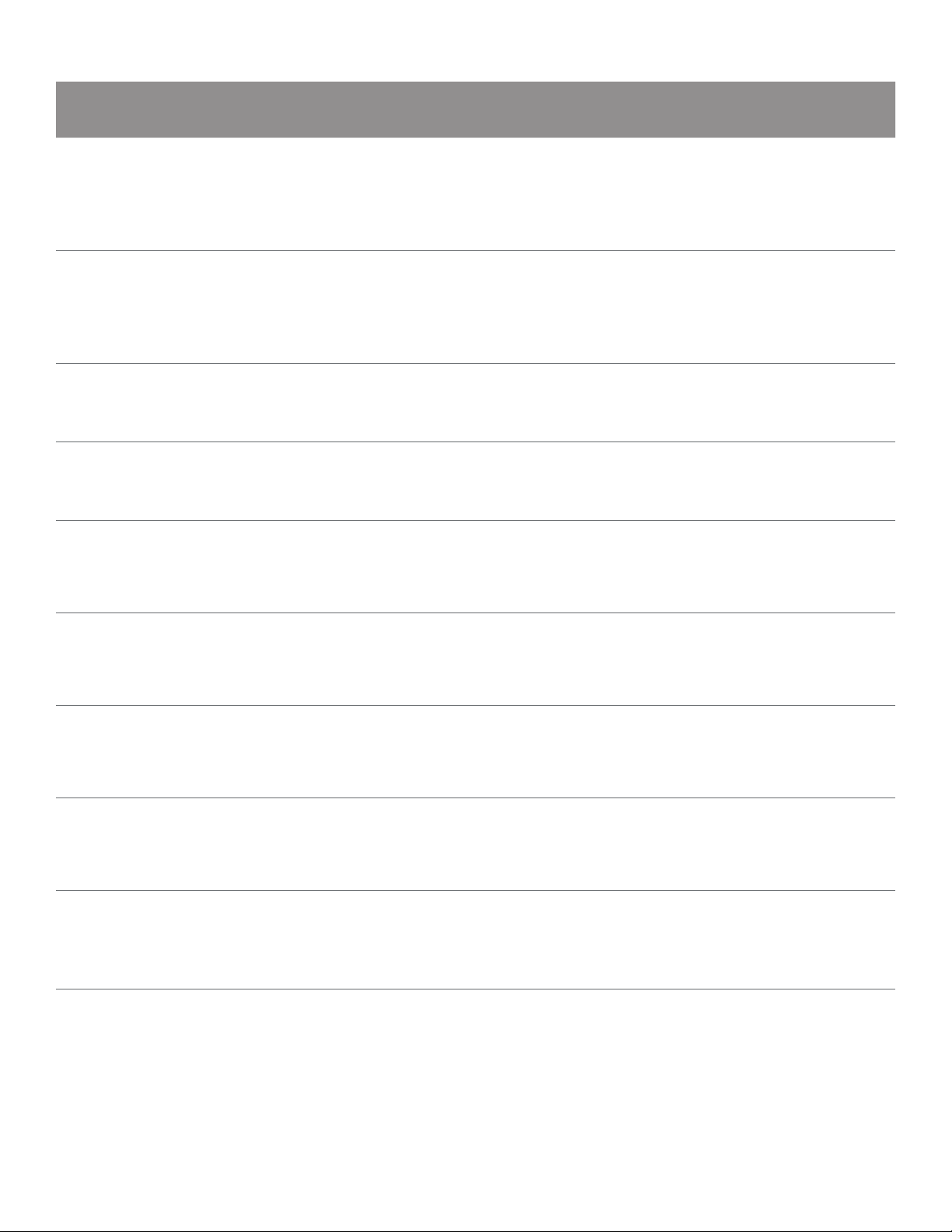

10

ERROR

CODE NAME DESCRIPTION POTENTIAL CAUSE TROUBLESHOOTING

E65

Ch1 pulse dir Pulses counted wrong

direction in channel 1

» Motor poles are crossed

» Hall sensor Cables are

crossed

• Check motor cable connections

and integrity (P2)

• Change Desk Leg

• Initialize the system (P1)

E66

Ch2 pulse dir Pulses counted wrong

direction in channel 2

» Motor poles are crossed

» Hall sensor Cables are

crossed

• Check motor cable connections

and integrity (P2)

• Change Desk Leg

• Initialize the system (P1)

E67

Ch3 pulse dir Pulses counted wrong

direction in channel 3

» Motor poles are crossed

» Hall sensor Cables are

crossed

• Check motor cable connections

and integrity (P2)

• Initialize the system (P1)

E68

Ch4 pulse dir Pulses counted wrong

direction in channel 4

» Motor poles are crossed

» Hall sensor Cables are

crossed

• Check motor cable connections

and integrity (P2)

• Initialize the system (P1)

E71

Ch1A shor t Short circuit on channel 1

[If T-splitter is used, short

circuit on 1A]

» Damage to motor cable

» Damage to cable exiting

leg (if applicable)

• Inspect motor cable for damage,

replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E72

Ch1B short Short circuit on channel 1

[If T-splitter is used, short

circuit on 1B]

» Damage to motor cable

» Damage to cable exiting

leg (if applicable)

• Inspect motor cable for damage,

replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E73

Ch2A short Short circuit on channel 2

[If T-splitter is used, short

circuit on 2A]

» Damage to motor cable

» Damage to cable exiting

leg (if applicable)

• Inspect motor cable for damage,

replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E74 Ch2B short Short circuit on channel 2

[If T-splitter is used, short circuit

on 2B]

» Damage to motor cable

» Damage to cable exiting

leg (if applicable)

• Inspect motor cable for damage,

replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E75 Ch3A short Short circuit on channel 3

[If T-splitter is used, short circuit

on 3A]

» Damage to motor cable

» Damage to cable exiting leg

(if applicable)

• Inspect motor cable for damage,

replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.

E76 Ch3B short Short circuit on channel 3

[If T-splitter is used, short circuit

on 3B]

» Damage to motor cable

» Damage to cable exiting leg

(if applicable)

• Inspect motor cable for damage,

replace if damaged

• Inspect cable exiting leg (if

applicable), replace if damaged.