Site this appliance beneath an extraction canopy for the removal of combustion

products.

When making the gas connection, fit an isolating cock into the supply line close to

the appliance for emergency shutdown or servicing purposes.

Installation must include sufficient ventilation to prevent the occurrence of

unacceptable concentrations of substances harmful to health in the room of

installation. There must be a minimum free area of 4.5cm2per kW of total heat

input.

Allow for a sufficient flow of fresh air for complete gas combustion.

Do not connect directly to any flue, ducting or mechanical extraction system.

The gas supply hose or tubing shall comply with national requirements in force and

shall be periodically examined and replaced as necessary. If flexible hose is used,

secure the appliance to the wall with a chain.

Install this appliance on a level surface ensuring all vents are unobstructed. Any

partitions, walls or furniture must be of non-combustible material.

Gas supply and connection

Check that the gas supply corresponds to that specified on the data plate.

Connection is at the rear of the unit via a ½ G female thread. The gas supply tubing

or hose shall comply with the national requirements in force and shall be

periodically examined and replaced as necessary.

An isolating cock should be fitted into the supply line close to the unit for emergency

shutdown or servicing purposes.

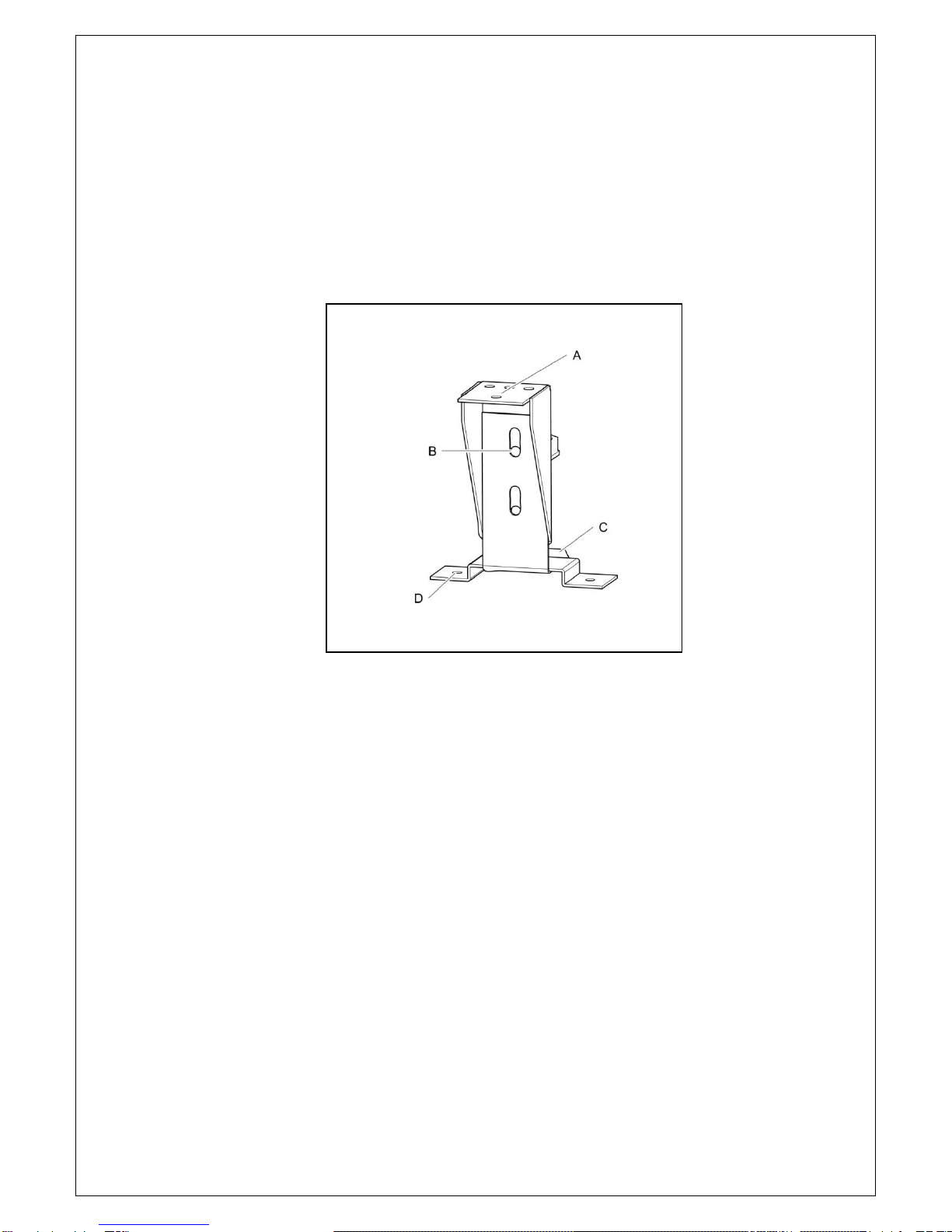

Fitting the Stabilising Kit (Fig 1)

The stabilising kit must be fitted to prevent accidental toppling of the appliance and

to ensure a safe working environment.

Fit the adjustable stabiliser centrally to the underside of the front cross member of

the appliance (A) using the M5 x 16 hex screws and shake proof washers provided.

Ensure the tongue of the bracket is facing rearward and adjusted to sit just off the

floor(C).